Preparation method of high thermal conductivity nano cellulose based electrical insulating composite film

A nanocellulose and electrical insulation technology is applied in the field of preparation of high thermal conductivity nanocellulose-based electrical insulation composite films, which can solve the problems of poor thermal conductivity of nanocellulose films, achieve optimal application value, high thermal conductivity, and improve insulation. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

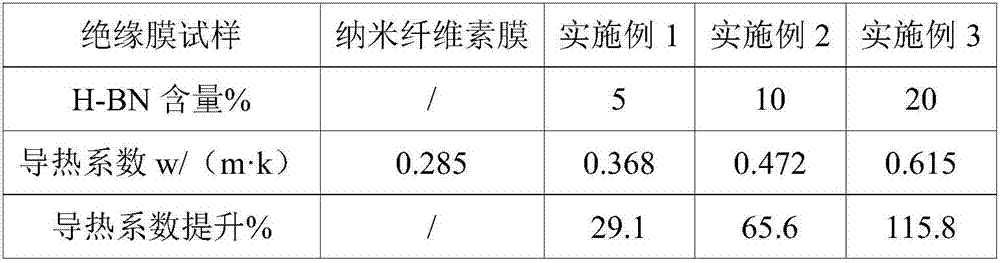

Examples

Embodiment 1

[0025] The bleaching kraft softwood pulp is subjected to beating pretreatment. The treatment process is as follows: the softwood pulp board is torn off and soaked in deionized water for 4 hours, and then torn into small pulp pieces of 25mm×25mm. Then pour the pulp into the Wall-E beater, add deionized water to the water tank, so that the pulp concentration reaches 2%, and start the beater to decompose until there are no small pulp lumps. Finally, hang the heavy thallium on the lever arm to start beating, and stop when the beating degree reaches 50-55°SR; take 5g of pretreated absolute dry slurry and add it to a three-necked flask, and then add 0.5g NaBr, 0.08g 2,2 , 6,6-Tetramethylpiperidine oxynitride radical (TEMPO) and 50mL NaClO solution were added to a three-necked flask, and deionized water was added to make the total volume 500mL, and the reaction was stirred at room temperature for 8h, during which dilute HCl and NaOH solution were used to Adjust the pH of the reaction...

Embodiment 2

[0027] The bleaching kraft softwood pulp is subjected to beating pretreatment. The treatment process is as follows: the softwood pulp board is torn off and soaked in deionized water for 4 hours, and then torn into small pulp pieces of 25mm×25mm. Then pour the pulp into the Wall-E beater, add deionized water to the water tank, so that the pulp concentration reaches 2%, and start the beater to decompose until there are no small pulp lumps. Finally, hang the heavy thallium on the lever arm to start beating, and stop when the beating degree reaches 50-55°SR; take 5g of pretreated absolute dry slurry and add it to a three-necked flask, and then add 0.5g NaBr, 0.08g 2,2 , 6,6-Tetramethylpiperidine oxynitride radical (TEMPO) and 50mL NaClO solution were added to a three-necked flask, and deionized water was added to make the total volume 500mL, and the reaction was stirred at room temperature for 8h, during which dilute HCl and NaOH solution were used to Adjust the pH of the reaction...

Embodiment 3

[0029] The bleaching kraft softwood pulp is subjected to beating pretreatment. The treatment process is as follows: the softwood pulp board is torn off and soaked in deionized water for 4 hours, and then torn into small pulp pieces of 25mm×25mm. Then pour the pulp into the Wall-E beater, add deionized water to the water tank, so that the pulp concentration reaches 2%, and start the beater to decompose until there are no small pulp lumps. Finally, hang the heavy thallium on the lever arm to start beating, and stop when the beating degree reaches 50-55°SR; take 5g of pretreated absolute dry slurry and add it to a three-necked flask, and then add 0.5g NaBr, 0.08g 2,2 , 6,6-Tetramethylpiperidine oxynitride radical (TEMPO) and 50mL NaClO solution were added to a three-necked flask, and deionized water was added to make the total volume 500mL, and the reaction was stirred at room temperature for 8h, during which dilute HCl and NaOH solution were used to Adjust the pH of the reaction...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com