Vacuum glass and construction door using vacuum glass

A technology of vacuum glass and glass, which is applied to buildings, building components, sustainable buildings, etc. It can solve the problems of troublesome construction, high cost, and opacity of ceramic points, and achieve the advantages of easy vacuuming, enhanced support force, and increased lighting rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

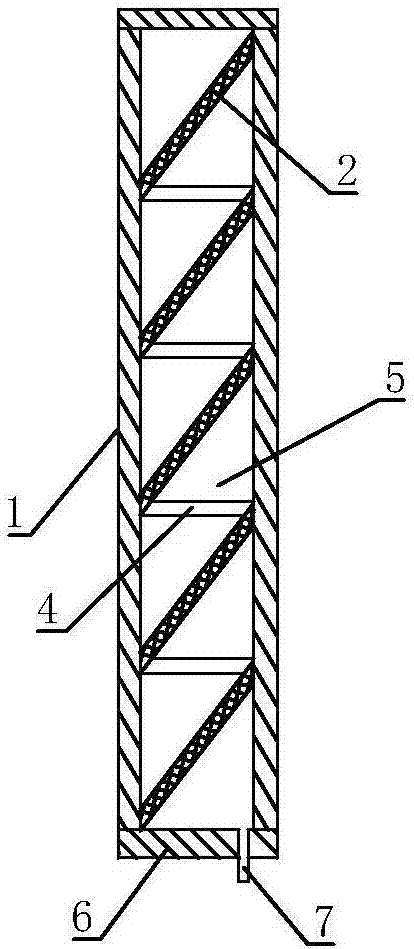

[0036] refer to figure 1 and figure 2 , the vacuum glass of the present embodiment comprises two oppositely arranged main glass plates 1, a side plate 6 is connected between each side of the two main glass plates 1, and the main glass plate 1 and the side plates 6 jointly form a glass lumen. A one-way valve 7 for evacuating the glass inner cavity is provided on the main glass plate 1 or on the side plate 6 .

[0037] The outside of the joint between the main glass plate 1 and the side plate 6 is coated with a sealant to increase the overall pressure bearing capacity of the vacuum glass.

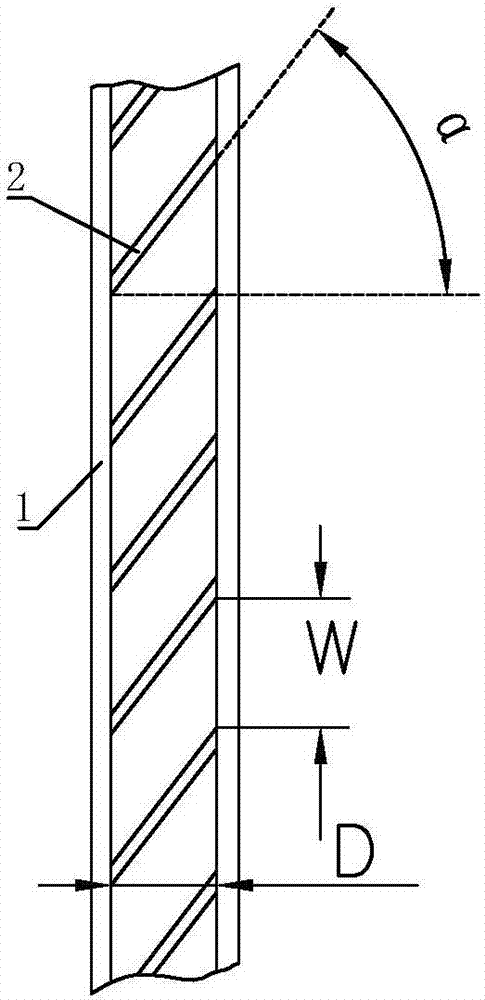

[0038] Multiple layers of first supporting layers 2 are arranged in parallel at intervals in the glass cavity, and each layer of first supporting layers 2 extends obliquely downward from the inner surface of the main glass plate 1 on one side to the inner surface of the main glass plate 1 on the other side, correspondingly A light-transmitting second support layer 4 is laterally connected...

Embodiment 2

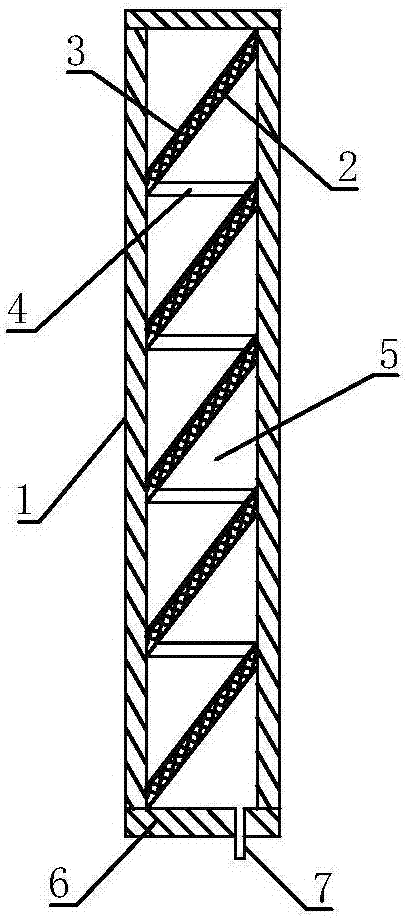

[0045]refer to image 3 , the structure of this embodiment is basically the same as that of Embodiment 1, the difference is that:

[0046] A solar energy utilization device is fixed on each first supporting layer 2 . The solar energy utilization device shown in this embodiment is a solar battery panel 3 , of course, the solar energy utilization device may also be a solar vacuum heat collecting tube or the like.

Embodiment 3

[0048] refer to Figure 4 The mechanism of this embodiment is basically the same as that of Embodiment 2, except that the second support layer 4 is arranged obliquely, with one end abutting on the upper first support layer 2 and the lower end abutting on the lower first support layer 2 . When one end of the second support layer 4 is in contact with the first support layer 2 and the other end is in contact with the main glass plate 1 on one side, the first support layer 2, the second support layer 4 and the main glass plate 1 jointly form a longitudinal The strong supporting structure with a triangular cross-section greatly enhances the supporting force and makes the vacuum glass stronger as a whole, which can meet the strength and firmness requirements of building blocks, and is suitable for use as building blocks, doors and windows, etc.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com