Water-cooling system and heat exchange method of Smart Rack integrated cabinet

A water-cooling system and a complete cabinet technology, applied in cooling/ventilation/heating renovation, electrical components, electrical equipment structural parts, etc., can solve problems such as loud noise and insufficient air supply in the machine room, and achieve the effect of enhancing heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

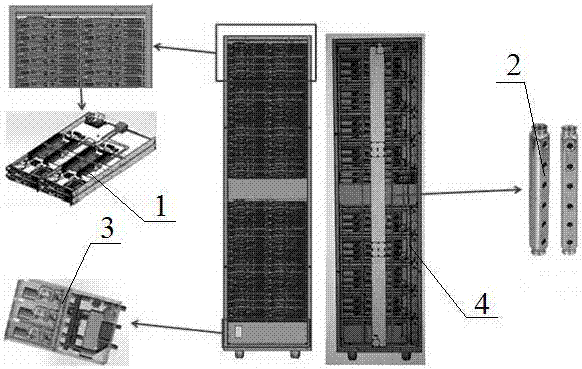

[0022] like figure 1 As shown, the water cooling system of the Smart Rack cabinet of the present invention includes a liquid cooling terminal 1 , a water diversion device 2 , a CDU control unit and a heat exchange unit 3 . The liquid cooling terminal 1 is located at the high power consumption device inside the node of the cabinet 4. The liquid-cooled terminal 1 is formed by connecting liquid-cooled plates through pipelines. The water diversion device 2 is arranged on the back of the cabinet 4 . The CDU control and heat exchange unit 3 is arranged under the cabinet 4, and a height of 4U is reserved at the bottom of the cabinet 4, and the CDU control and heat exchange unit 3 is installed. The water diversion device 2 is connected to the liquid cooling terminal 1, the CDU control and heat exchange unit 3 through blind-mating quick connectors.

Embodiment 2

[0024] In the water-cooled heat exchange method of the Smart Rack complete cabinet of the present invention, the cold medium enters the liquid-cooled terminal 1 from the water inlet of the liquid-cooled terminal 1 along the pipeline, and is carried out by the liquid-cooled plate and the internal high-power consumption device of each U node in the cabinet 4. Heat exchange, transfer the heat to the cold medium, and take it out of the node by the water outlet. The heat medium coming out of each U node is collected by the water diversion device 2 and transported to the heat exchanger of the CDU control and heat exchange unit 3, through which heat exchange occurs with the cold water provided by the external water tower, and the heat exchange occurs through the wall during this process. Without mixing, the heat is transferred to an external water tower and taken out of the engine room. The hot medium turns into cold medium after passing through the heat exchanger, and is evenly retu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com