Polyisocyanate composition and its production method, blocked polyisocyanate composition and its production method, resin composition, and cured product

A polyisocyanate and diisocyanate technology, applied in the fields of polyisocyanate composition and its manufacture, blocked polyisocyanate composition and its manufacture, resin composition, and cured products, can solve the problems such as polyisocyanate is difficult to disperse, and achieve excellent Effect of water resistance and heat resistance strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

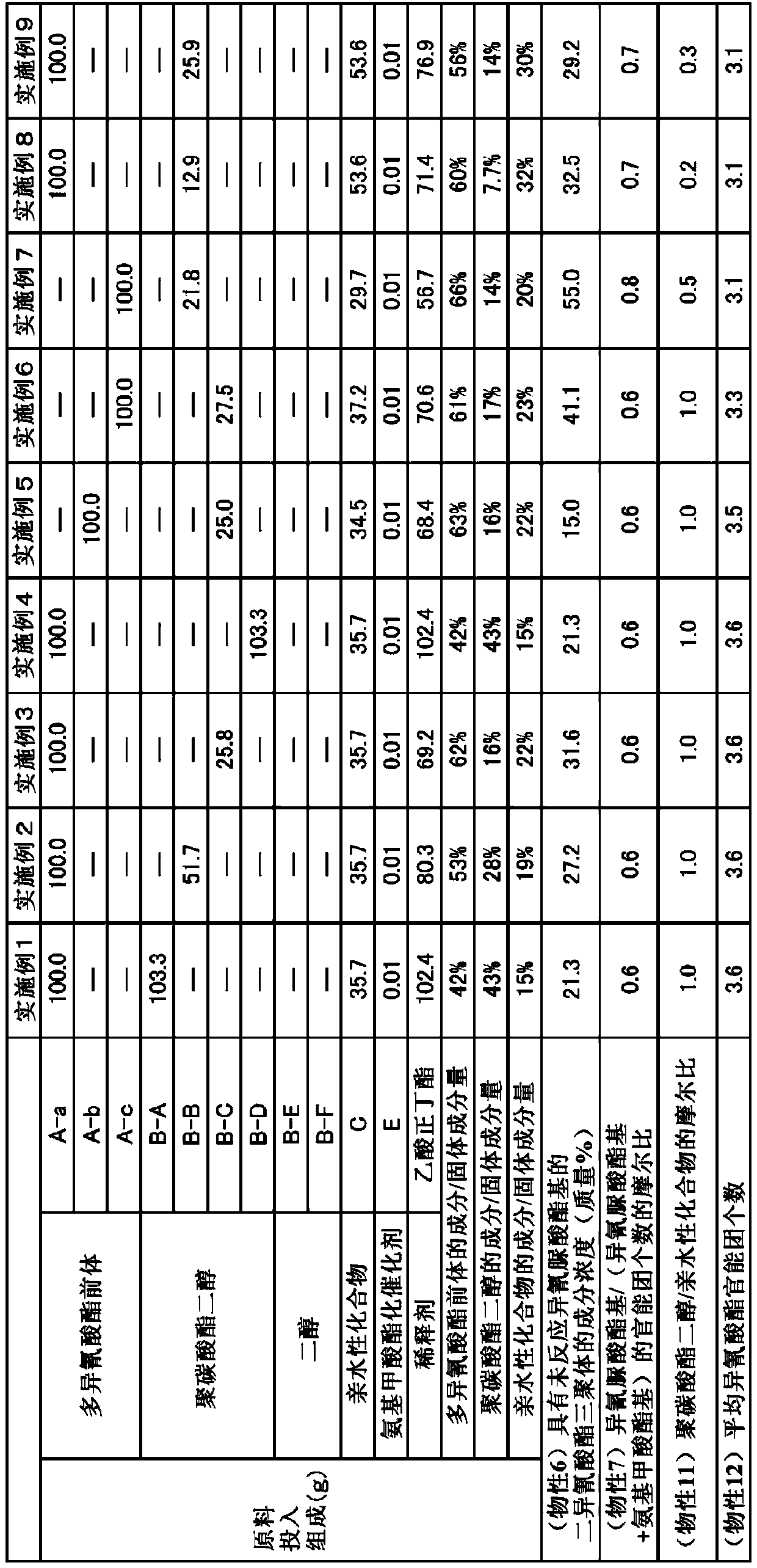

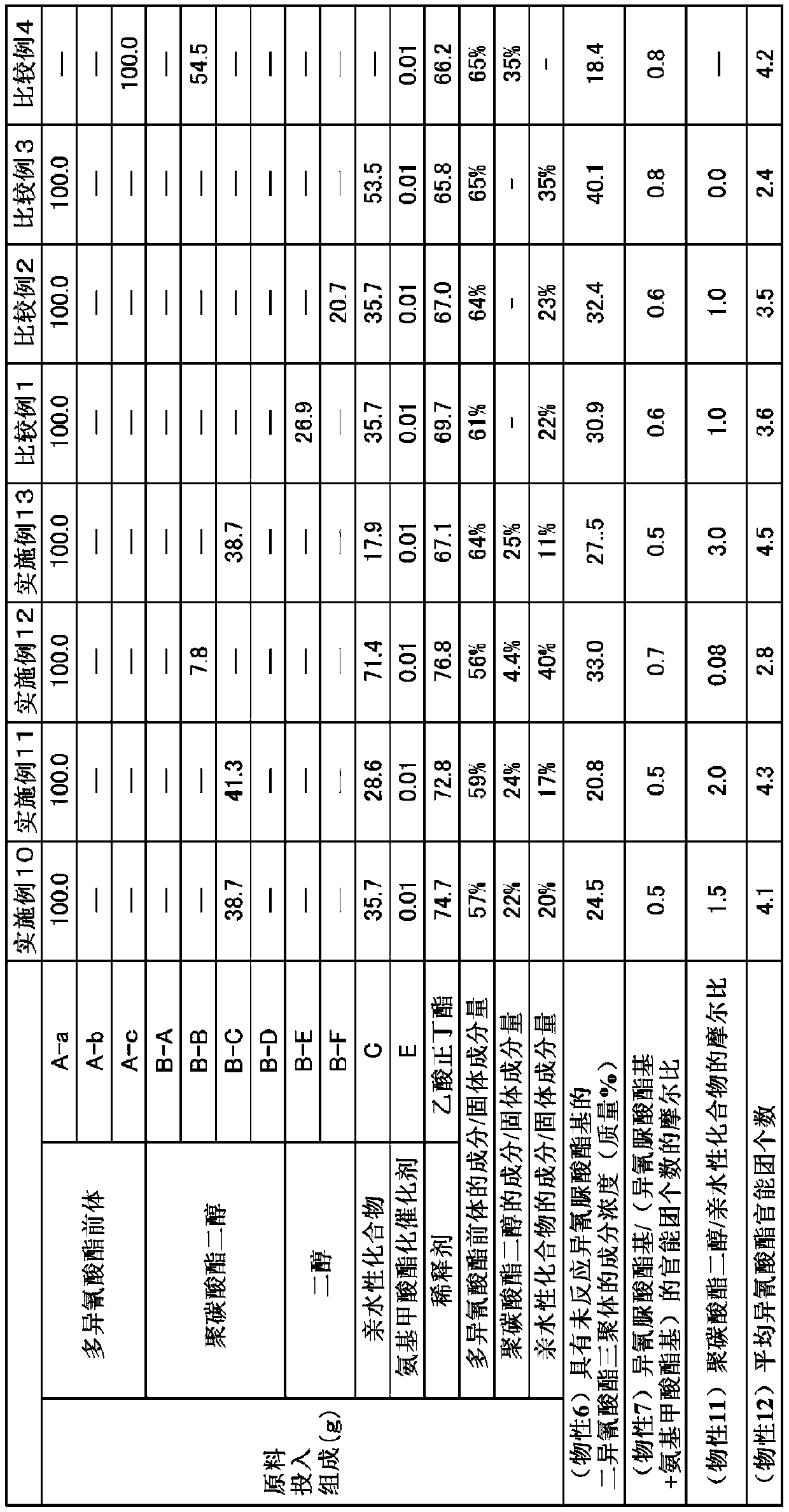

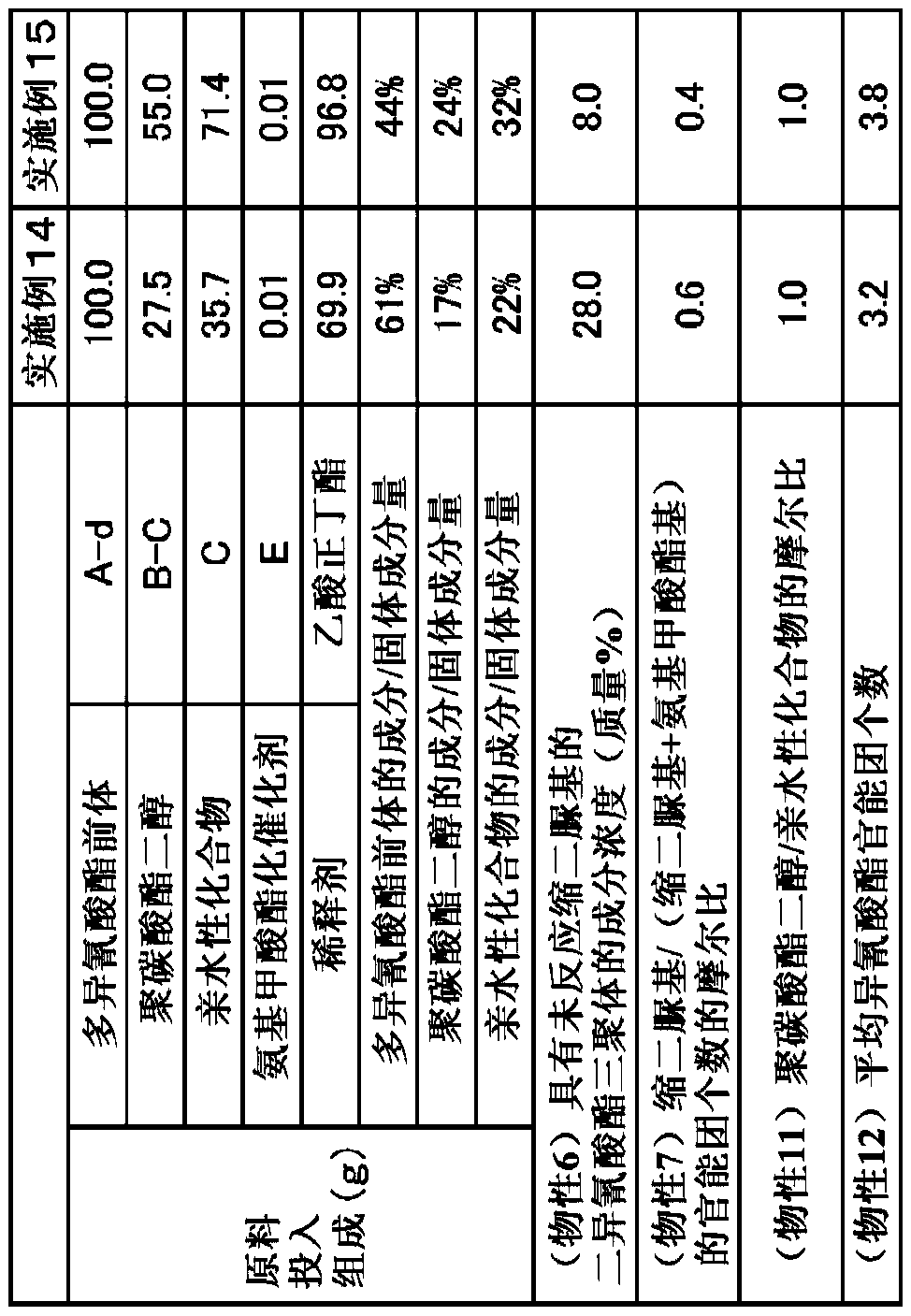

[0182] Specific examples and comparative examples are shown below, and the present embodiment is described in more detail, but the present embodiment is not limited at all by the following examples and comparative examples within the scope not exceeding the gist thereof. Various physical properties and evaluations in Examples and Comparative Examples were measured and evaluated as follows.

[0183] (Properties 1) Yield

[0184] Using the polyisocyanate precursor as a sample, the yield of the polyisocyanate precursor was determined by measuring the refractive index of the reaction liquid.

[0185] (Properties 2) Viscosity

[0186] Using the polyisocyanate precursor as a sample, the viscosity of the polyisocyanate precursor at 25°C was determined using an E-type viscometer RE-80U (manufactured by Toki Sangyo Co., Ltd.).

[0187] (Property 3) Isocyanate group concentration

[0188] In the Erlenmeyer flask, 1 to 3 g (Wg) of the polyisocyanate precursor was precisely weighed, an...

Embodiment 28~42

[0236] Examples 28 to 42, Comparative Examples 10 to 14: 80°C, 60 minutes

Embodiment 43~54

[0237] Examples 43 to 54, Comparative Examples 15 to 19: 160°C, 60 minutes

[0238] A rubber ring having a diameter of 2 cm was placed on the obtained coating film, and water was added dropwise thereto. In order to prevent volatilization, a watch glass was placed on the top, and it was left to stand at 23°C for 2 days. After 2 days, the water was removed, and the haze before and after the dropwise addition of water was measured. The haze value of the coating film was measured according to JIS K7361 using a trade name Haze meter manufactured by Suga Test Instruments Co., Ltd.

[0239] The evaluation criteria are as follows. In addition, when precipitation etc. generate|occur|produced in the said coating composition, it described as "evaluation impossible".

[0240] ○: The difference between the haze values before and after the dropwise addition of water is less than 0.5, and the water resistance is good.

[0241] ×: The difference between the haze values before and afte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com