Preparation method of sheet-shaped bismuth titanate and bismuth oxychloride composite material

A technology of bismuth titanate, bismuth oxychloride, and composite materials, which is applied in chemical instruments and methods, water/sludge/sewage treatment, water pollutants, etc., can solve the problems of no sheet catalyst, complicated operation steps, and high cost. Achieve the effects of reducing the hole-electron recombination rate, simple process and flow, and regular morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Take 0.34g of bismuth oxide, 0.087g of titanium dioxide, 1.359g of potassium chloride and 1.067g of sodium chloride in a mortar, and their molar ratios are 2:3:50:50, and grind evenly. The ground powder was transferred to a quartz boat and calcined at 800° C. for 2 h to obtain flaky bismuth titanate. Then take the bismuth titanate powder prepared above in a beaker, add 1 mol / L dilute hydrochloric acid, and stir for 4 hours. Filtering, washing and drying to obtain bismuth titanate bismuth oxychloride composite photocatalyst.

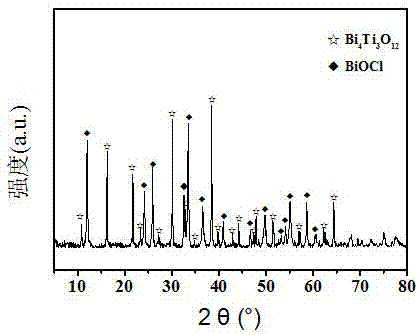

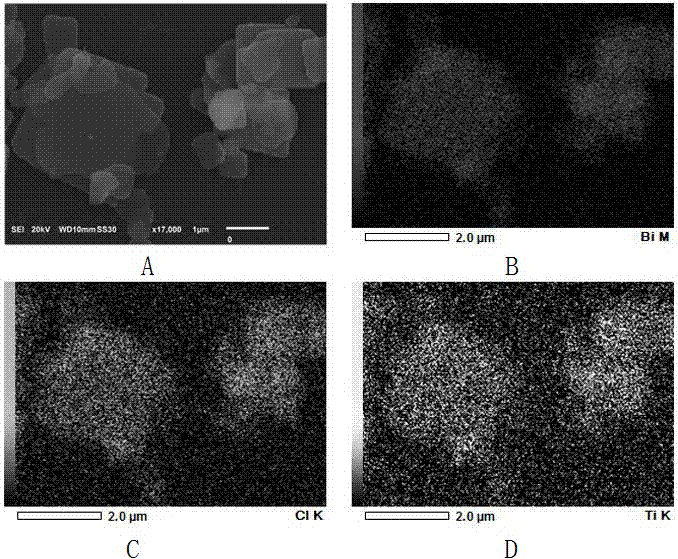

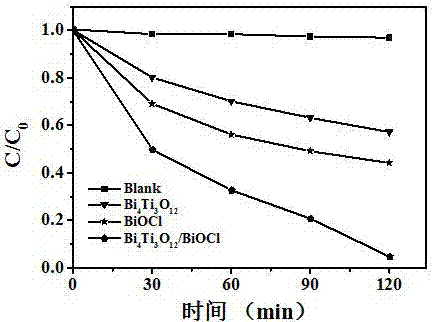

[0025] figure 1 The XRD diffraction pattern of the prepared material, the peaks at each position in the figure belong to bismuth titanate or bismuth oxychloride, and compared with the standard JCPDS card (21-1272, 82-0485), it can be determined that the prepared one is good crystallinity Bismuth titanate bismuth oxychloride composite powder material; Figure 2 is a scanning and mapping photo. From the scanning picture, it can be seen that some sma...

Embodiment 2

[0027] Take 0.34g of bismuth oxide, 0.087g of titanium dioxide, 0.815g of potassium chloride and 0.640g of sodium chloride in a mortar, and their molar ratios are 2:3:30:30, and grind evenly. The ground powder was transferred to a quartz boat and calcined at 600° C. for 0.5 h to obtain bismuth titanate. Then take the bismuth titanate powder prepared above in a beaker, add 4 mol / L dilute hydrochloric acid, stir for 1 hour, filter, wash and dry.

Embodiment 3

[0029] Take 0.34g of bismuth oxide, 0.087g of titanium dioxide, 1.087g of potassium chloride and 0.853g of sodium chloride in a mortar, their molar ratios are 2:3:40:40, and grind evenly. The ground powder was transferred to a quartz boat and calcined at 700°C for 1 hour to obtain bismuth titanate. Then take the bismuth titanate powder prepared above in a beaker, add 2 mol / L dilute hydrochloric acid, stir for 2 hours, filter, wash and dry.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap