Disc polishing machine

A technology of polishing machine and disk, which is applied in the direction of surface polishing machine tools, grinding/polishing equipment, grinding/polishing safety devices, etc., and can solve problems such as uneven polishing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

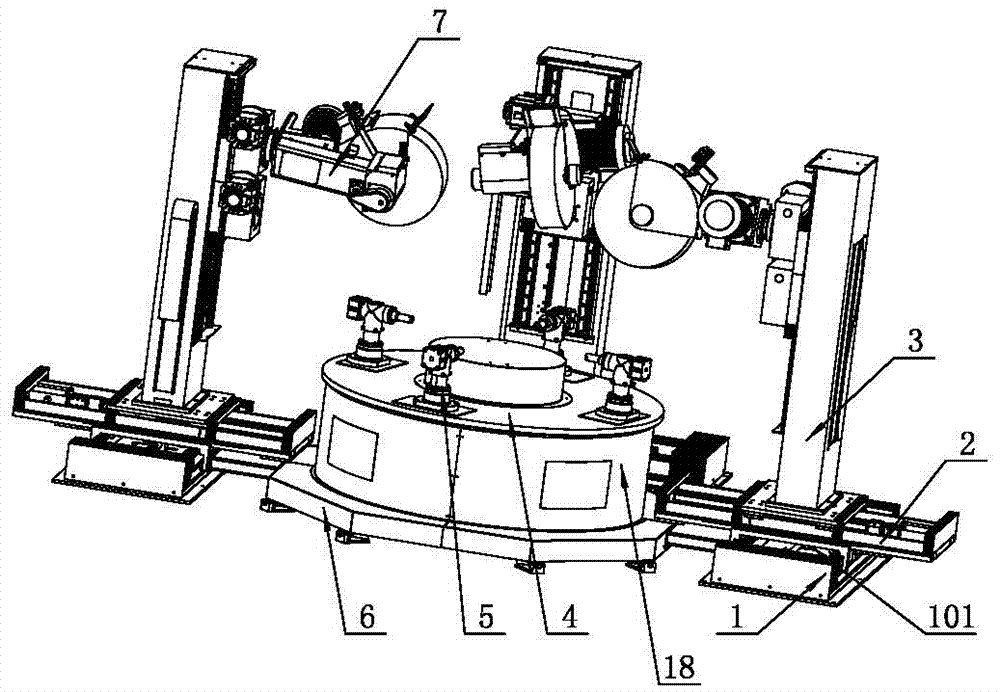

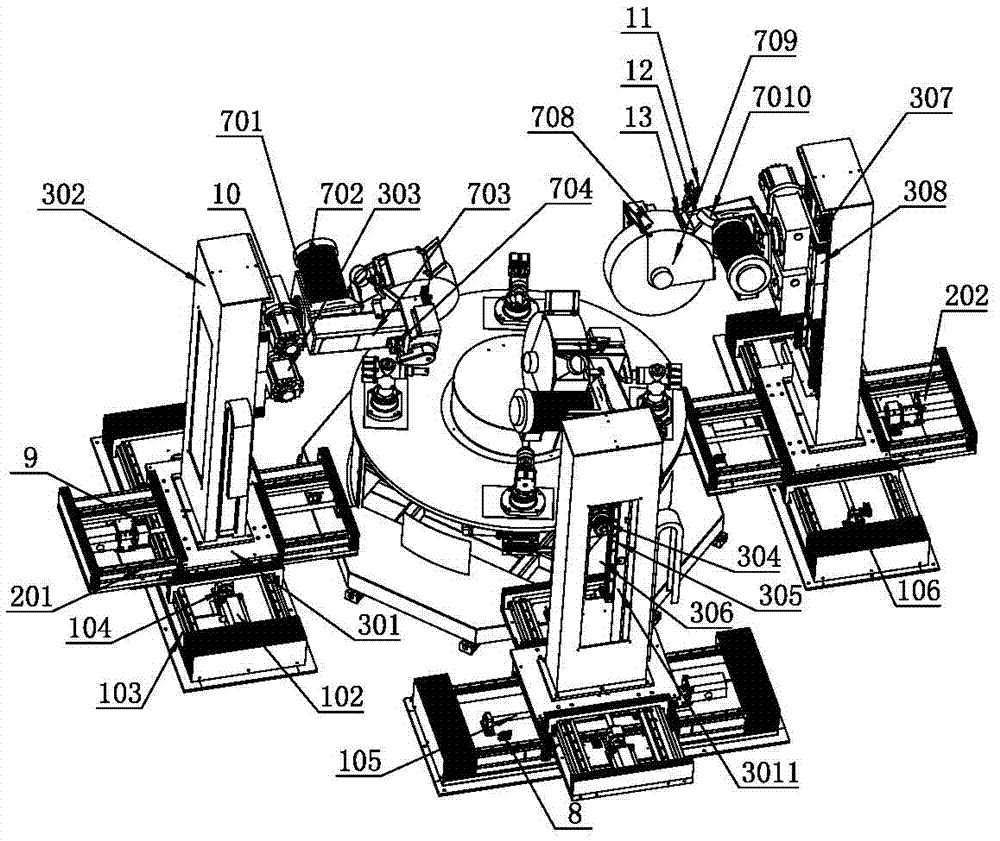

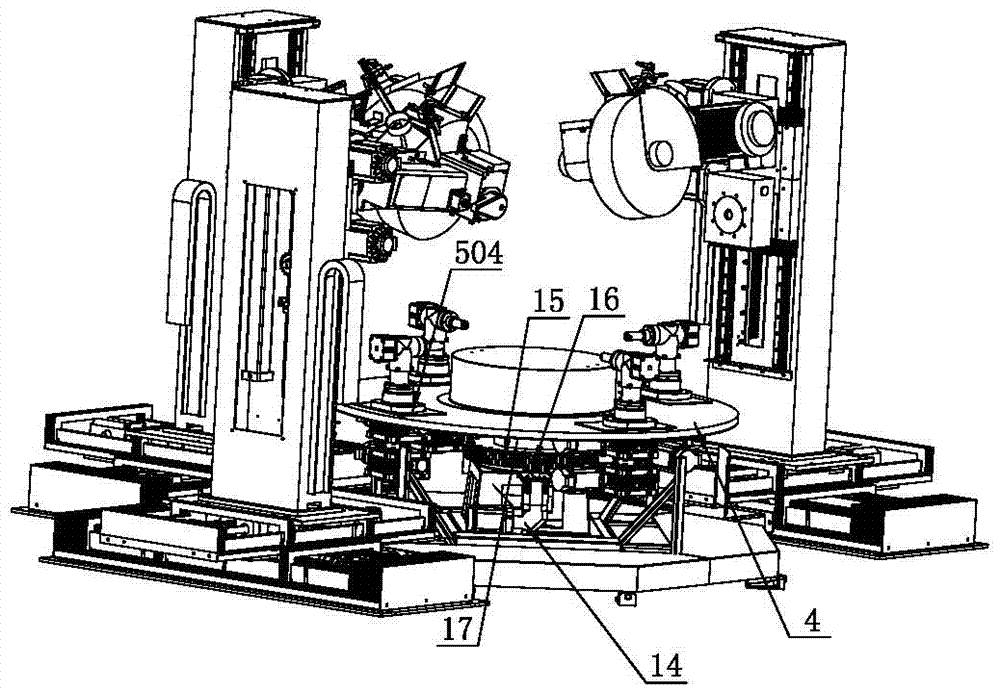

[0028] like Figure 1-10 The disc polishing machine shown includes a rotatable disc 4 on which 4 fixtures 5 for clamping the workpiece are arranged, and 3 fixtures 5 are arranged at intervals around the disc 4 for polishing the workpiece. The polishing device 7, the polishing device 7 polishes the workpiece on the fixture 5, and the polishing device 7 can move in the horizontal and vertical directions and can rotate;

[0029] In order to realize the lateral movement of the polishing device 7, it also includes a left and right movement mechanism 1, a front and rear movement mechanism 2 and a lifting mechanism 3. The left and right movement mechanism 1 includes a lower base 103, which is connected with a linear drive device 106, and the front and rear movement mechanism 2 Including an upper base 201, the upper base 201 is connected with a linear drive device 2 202, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com