Fiber-reinforced concrete for rapid repair of airport pavement, preparation and application

A fiber reinforced concrete and concrete technology, applied in the field of concrete, can solve the problems of poor airport pavement, and achieve the effects of high early strength, high later volume stability and high durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

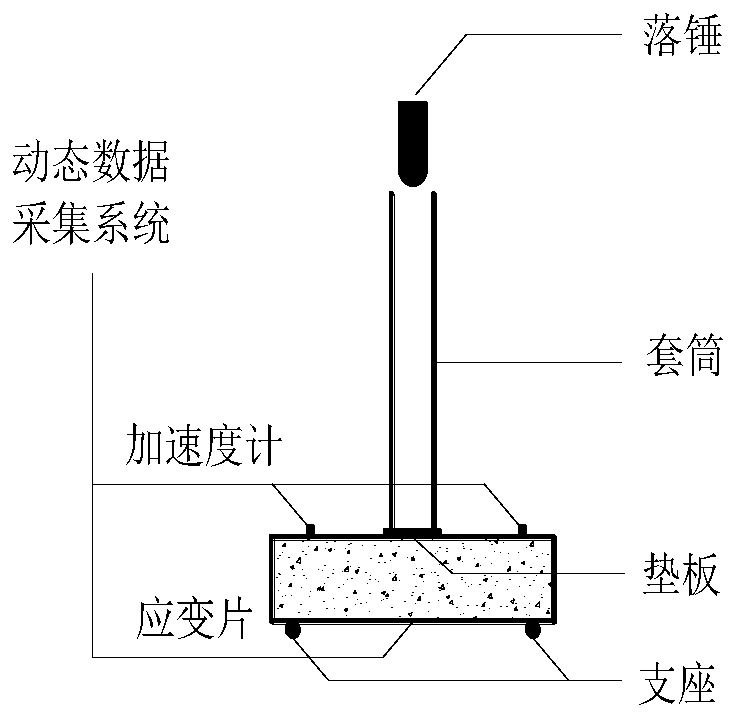

Image

Examples

Embodiment

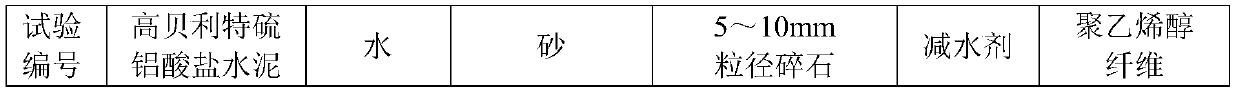

[0025] Numbers 2, 3, and 4 are examples, and number 1 is a comparative example.

[0026] The typical material mix ratios used in each embodiment and the comparative example are listed in Table 1.

[0027] Table 1 Example Mixing Ratio

[0028]

[0029]

[0030] A detailed description of the materials used in Table 1:

[0031] The cement used has a specific surface area of 480m 2 / kg of BS-HFR42.5 high Belite sulphoaluminate cement.

[0032] The sand is ordinary medium sand, the maximum particle size is not more than 2.5 mm, and the fineness modulus is 2.5.

[0033] The water used meets the requirements of "Water Standard for Concrete" JGJ 63-06. The quality of water in Table 1 is the quality of the water contained in the water reducing agent.

[0034] The stones are ordinary melon stones of 5-10 mm.

[0035] The polyvinyl alcohol fiber used has a diameter of 45μm, a length of 12mm, and a density of 1.3×10 3 kg / m 3 .

[0036] The water-reducing agent used is a high-efficiency composite wate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com