Preparation method of cationic polymerization bifunctional initiator and telechelic polyisobutene

A cationic polymerization, bifunctional technology, which is applied in the application field of synthesizing high end-capping selective polyisobutylene, achieves the effects of reducing cost, increasing polymerization temperature and reducing energy consumption

Active Publication Date: 2017-09-01

BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

View PDF4 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

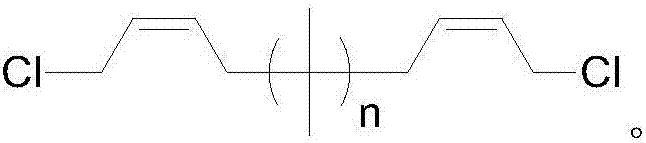

[0004] The literature (Macromolecules 2006,39,6861-6870) reported that 1,3-butadiene was used as an end-capping agent to synthesize a structure containing double bonds at the end, but because of the selection of traditional initiators, it could not be completely transformed into

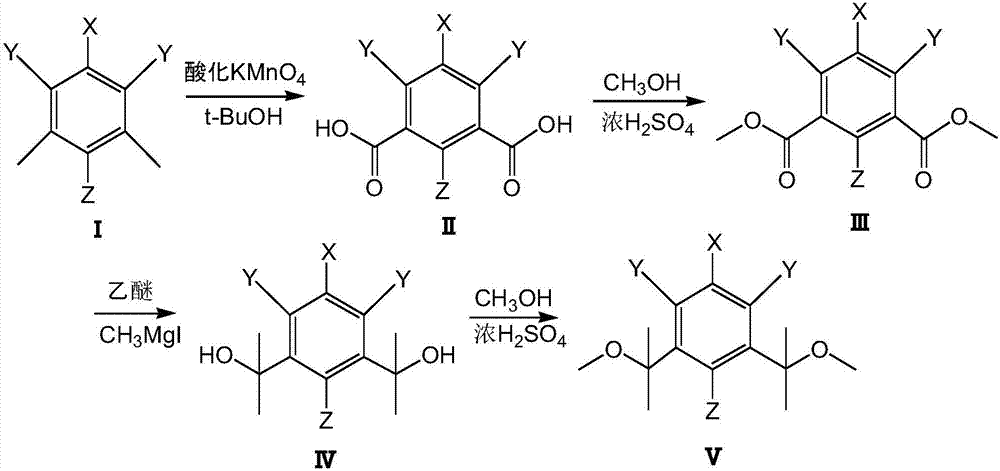

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

example 2

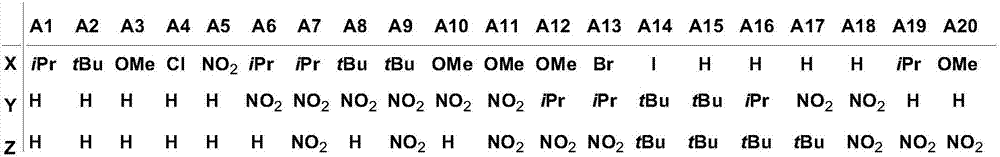

[0027] In Example 2, V was synthesized from A2. The synthesis procedure was similar to Example 1, and the yield was about 56%.

example 3

[0028] In Example 3, V was synthesized from A3. The synthesis procedure was similar to that in Example 1, and the yield was about 58%.

example 4

[0029] Example 4, starting from A4 to synthesize V, the synthesis steps are similar to Example 1, and the yield is about 55%.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a preparation method of a novel cationic polymerization bifunctional initiator. The initiator is produced to a kilo grade scale meeting industrial production from a laboratory gram-grade scale, so that the synthetic cost of the initiator is greatly lowered. By developing a series of novel initiator derivatives, the brand new initiator which is higher in initiating efficiency, lower in energy consumption and higher in production efficiency are found, and telechelic polyisobutene, the functional groups (hydroxyl, double bonds or chlorine group) of which are fully terminated and the molecular structure of which is controllable, can be synthesized.

Description

Technical field [0001] The invention belongs to the technical field of polymer material preparation, and particularly relates to a series of preparation methods of a series of novel isobutylene cationic polymerization bifunctional initiators, and the application in the synthesis of high end-capping selectivity polyisobutylene. Background technique [0002] Telechelic type polyisobutene is a very useful macromonomer and synthetic intermediate. It can be used to prepare rocket propellant due to the thermal stability, air tightness, hydrophobicity and impermeability brought by its saturated carbon chain structure. The adhesive can also react with diisocyanate to generate polyisobutylene-based polyurethane for use in the biomedical field. The synthesis methods of telechelic polyisobutylene are mainly divided into two categories: one is polymer degradation, that is, butyl rubber is degraded by ozonization, and then reduced with aluminum hydride files or other reducing agents to obtain...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C07C41/09C07C43/164C07C43/205C07C43/174C07C201/12C07C205/34C07C205/37C08F210/10C08F236/06C08F4/00

CPCC07C29/36C07C41/09C07C51/16C07C67/08C07C201/12C08F210/10C07C43/164C07C43/205C07C43/174C07C205/34C07C205/37C07C63/15C07C69/76C07C33/26C07C63/72C07C65/21C07C205/57C07C33/46C07C205/19C08F236/06C08F4/00

Inventor 伍一波张敏张民郭文莉李树新崔秀国杨丹王浩胡月丽

Owner BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com