Organotin molecularly imprinted polymer microsphere, solid phase extraction column and use of solid phase extraction column

A technology of molecular imprinting and polymers, which is applied in the fields of alkali metal compounds, inorganic chemistry, separation methods, etc., can solve the problems of non-compliance, increased extraction times and costs, and molecularly imprinted polymers have not yet been seen, and achieves simple steps and purification effects Good, highly selective and adsorptive as well as class-specific effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

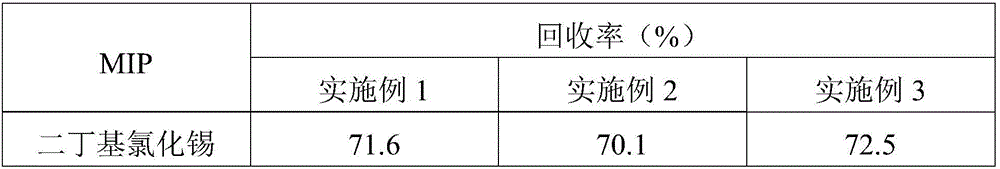

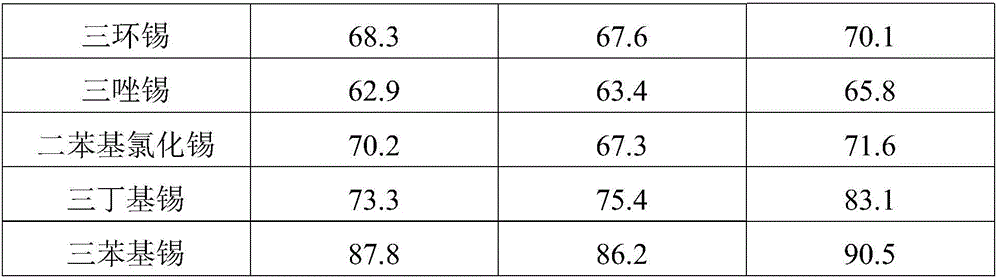

[0061] This example provides a preparation method of organotin molecularly imprinted polymer microspheres, and its application as a MISPE column prepared as a filler.

[0062] A) Dissolve the double template molecules of dibutyltin chloride (DBT) and diphenyltin chloride (DPT) and 0.14mL methacrylic acid (MAA) in 2mL dichloromethane, then add a certain amount of acetonitrile , pre-action in the oscillator for 25 minutes;

[0063] Wherein, the final concentrations of DBT and DPT in the final inert solvent system are each 0.1mmol; the final concentration of the methacrylic acid is 0.7mmol;

[0064] B) Add 0.1825mL TRIM (final concentration 0.6mmol) and 40.0mg AIBN to the mixture in A) and mix thoroughly. Ultrasound at room temperature for 5 minutes, nitrogen deoxygenation for 10 minutes, and then seal;

[0065] C), heating in a constant temperature water bath at 55°C for 26 hours, cooling, centrifuging, sieving, discarding the supernatant to obtain a precipitate, and then dryi...

Embodiment 2

[0070] This example provides a preparation method of organotin molecularly imprinted polymer microspheres, and its application as a MISPE column prepared as a filler.

[0071] A) Dissolve the double template molecules of dibutyltin chloride (DBT) and diphenyltin chloride (DPT) and 0.3mL methacrylic acid (MAA) in 2mL of dichloromethane, then add a certain amount of acetonitrile , pre-action in the oscillator for 35 minutes;

[0072] Wherein, the final concentrations of DBT and DPT in the final inert solvent system are each 0.3mmol; the final concentration of the methacrylic acid is 1.5mmol;

[0073] B) Add 0.5475mL TRIM (final concentration 1.8mmol) and 40.0mg AIBN to the mixture in A) and mix thoroughly. Ultrasound at room temperature for 5 minutes, nitrogen deoxygenation for 10 minutes, and then seal;

[0074] C), heating in a constant temperature water bath at 65°C for 22 hours, cooling, centrifuging, sieving, discarding the supernatant to obtain a precipitate, and then dr...

Embodiment 3

[0079] This example provides a preparation method of organotin molecularly imprinted polymer microspheres, and its application as a MISPE column prepared as a filler.

[0080] A), dissolve the double template molecules of dibutyltin chloride (DBT) and diphenyltin chloride (DPT) and 0.24mL methacrylic acid (MAA) in 2mL of dichloromethane, then add a certain amount of acetonitrile , pre-action in the oscillator for 30min;

[0081] Wherein, the final concentrations of DBT and DPT in the final inert solvent system are each 0.2mmol; the final concentration of the methacrylic acid is 1.2mmol;

[0082] B) Add 0.365mL TRIM (final concentration 1.2mmol) and 40.0mg AIBN to the mixture in A) and mix thoroughly. Ultrasound at room temperature for 5 minutes, nitrogen deoxygenation for 10 minutes, and then seal;

[0083] C), heating in a constant temperature water bath at 60°C for 24 hours, cooling, centrifuging, sieving, discarding the supernatant to obtain a precipitate, and then drying...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com