Soft soil area railway station platform subsidence mini-pile repairing structure and construction method

A technology for repairing structures and micro-piles, which is applied in basic structure engineering, sheet pile walls, buildings, etc., can solve the problems of narrow construction site, limited construction height, and high construction equipment, and achieve the effect of avoiding intrusion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

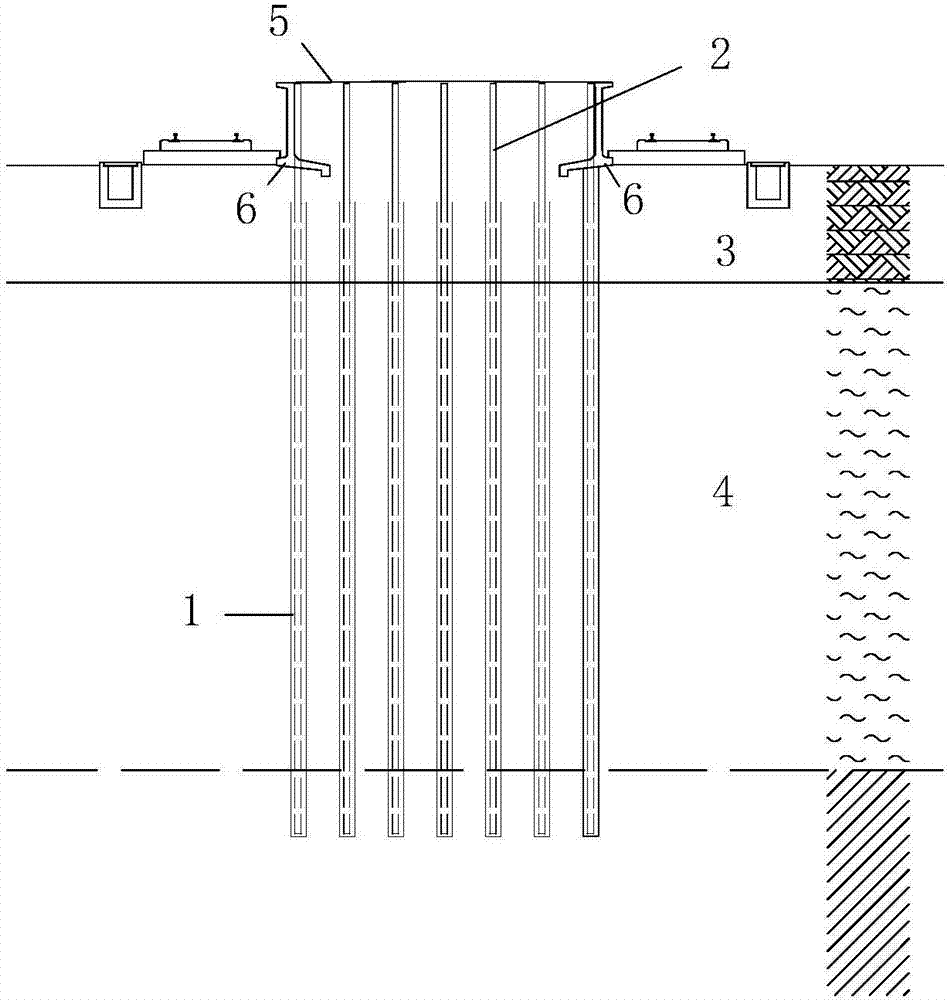

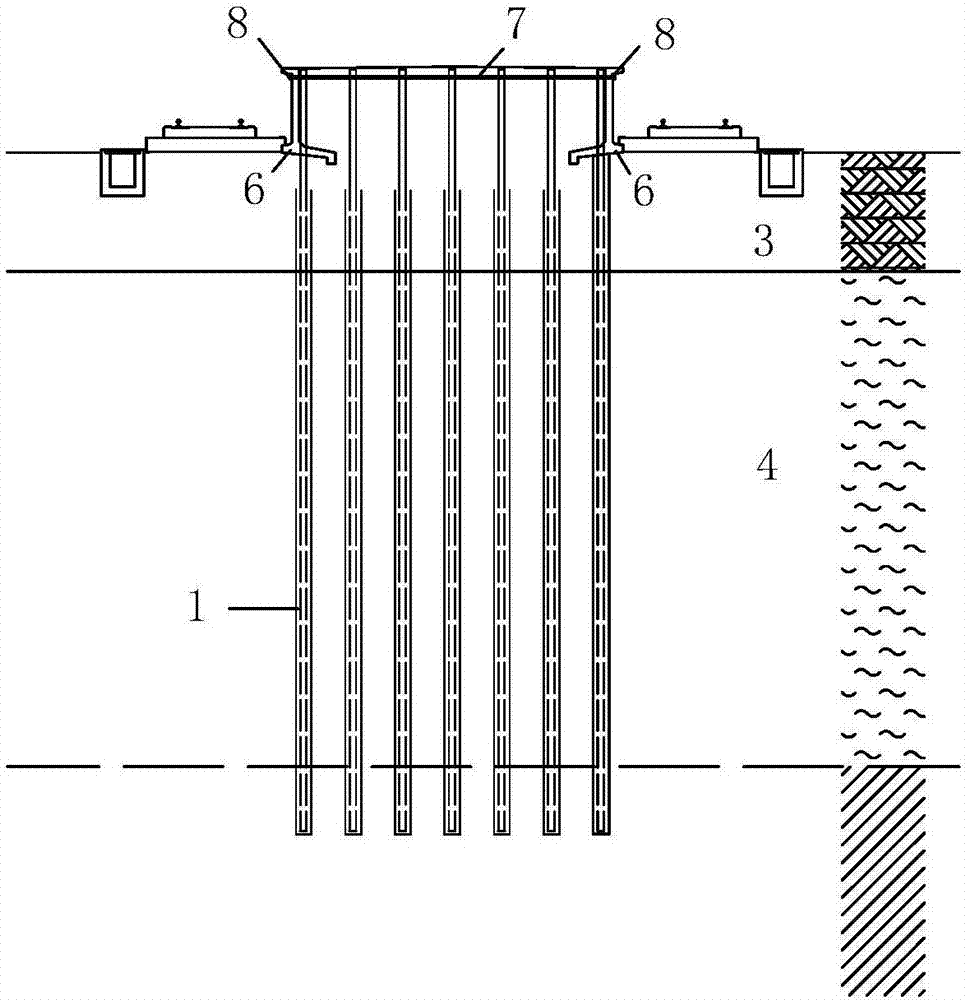

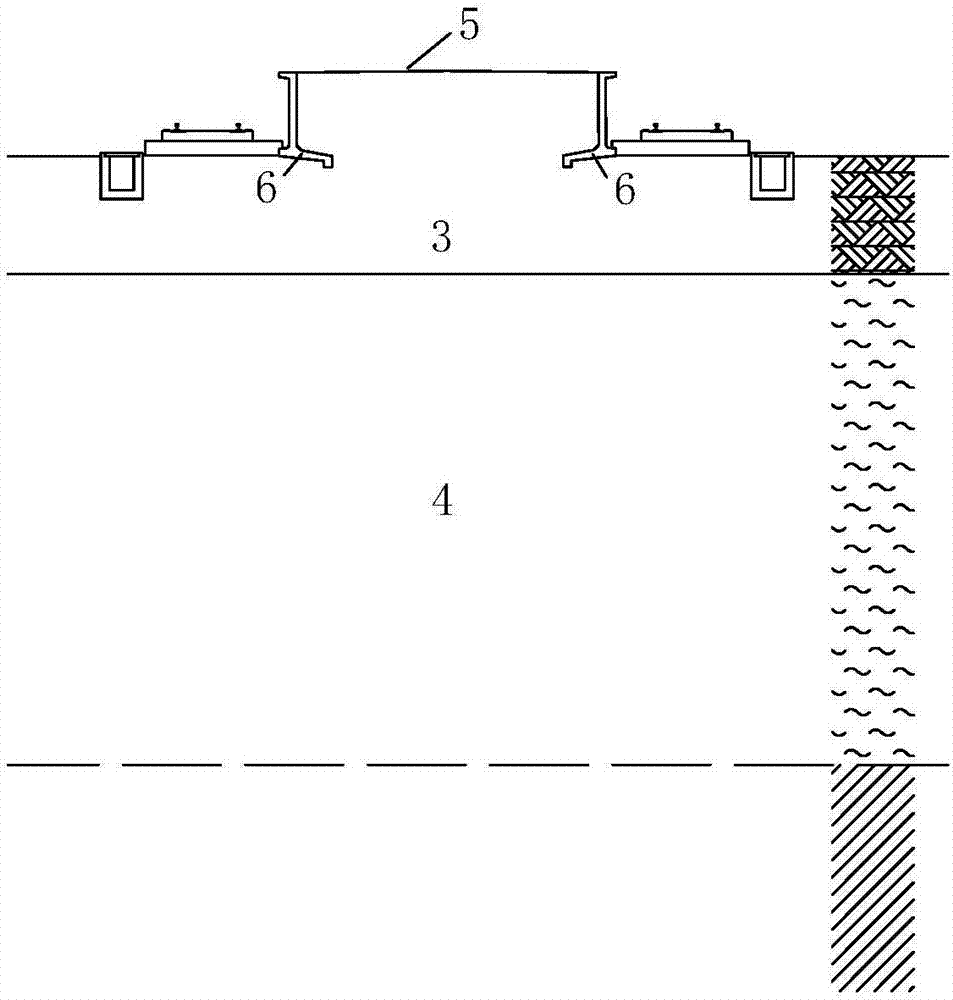

[0030] Such as figure 1 As shown in the present invention, a subsidence mini-pile repair structure of a railway station platform in a soft soil area includes reinforcement holes 9 arranged in the subgrade fill soil 3 in the area to be repaired on the platform. The hollow seamless steel pipe 2 is adopted, the outer diameter of the hollow seamless steel pipe 2 is 90-200 mm, the wall thickness is 5-10 mm, and the vertical direction is connected by joints. The hollow seamless steel pipe 2 is provided with grouting eyes for grouting out along the periphery, and the grouting eyes are arranged in a quincunx shape. The cement slurry is injected from the top of the hollow seamless steel pipe 2 and solidified inside and outside the hollow seamless steel pipe 2 to form a micro pile 1. The bottom of the micro pile 1 goes deep below the soft soil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com