Environmental protection and energy saving pouring-type wall body and construction method thereof

A technology of environmental protection, energy saving and construction method, applied in the direction of building structure, wall, building, etc., can solve the problems of cracks in the joint, how much the workload is reduced, not generally recognized by the construction industry, etc., to prevent the collapse of the wall, The effect of ensuring property life safety and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

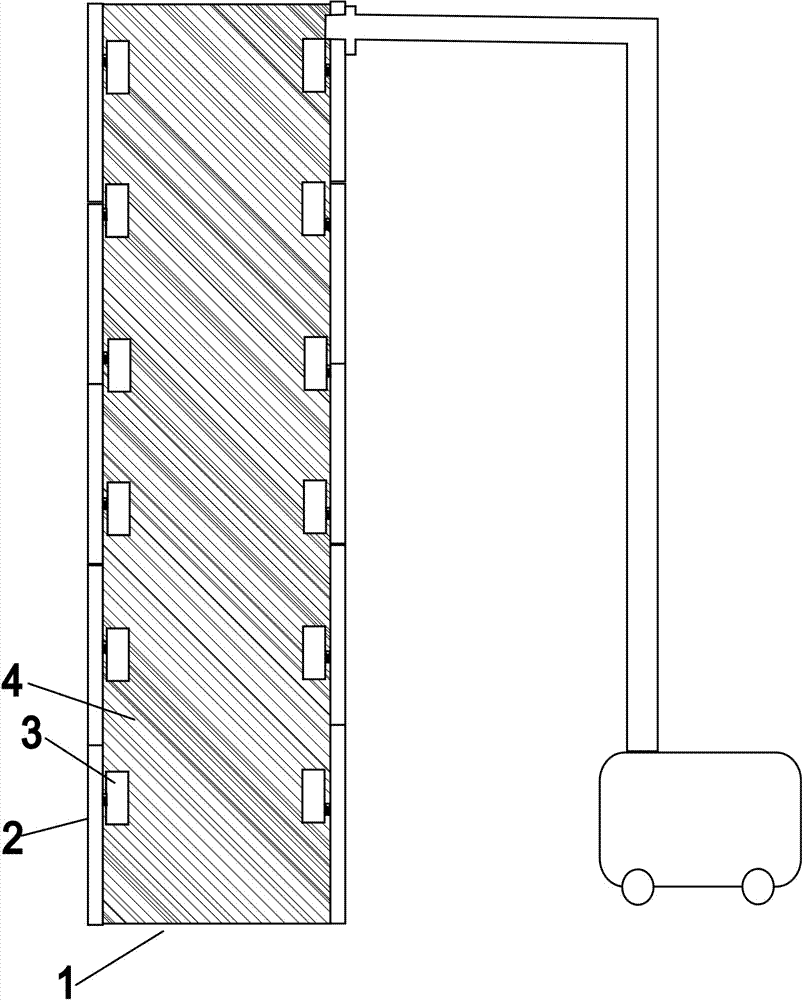

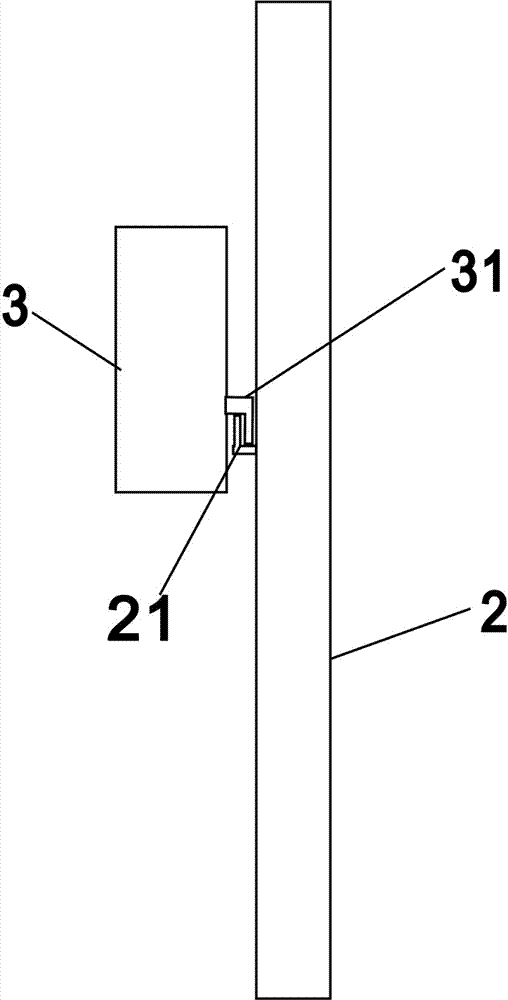

[0023] Such as Figure 1-2 As shown, an environment-friendly and energy-saving pouring wall body, the body wall 1 includes a panel 2, a metal bracket 3 and a pouring material layer 4, the back of the panel is provided with a hook 21, and the metal bracket 3 is formed by a telescopic column The side of the metal bracket 3 is provided with buttons 31, and the body wall 1 skeleton is composed of two or more metal brackets 3 parallel to each other. The exterior of the entire metal bracket 3 is covered by a plurality of panels 2, and the hooks 21 and the buttons 31 are fastened to each other. To prevent the panel 2 from falling off and deforming during pouring, one or more panels 2 are provided with a pouring port or a socket switch reserved port, and the pouring material layer 4 fills the interior between the panels 2 hung by the two sets of metal brackets space, and wrapped in metal brackets.

[0024] The panel is a light alloy cement composite panel, and the pouring material la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com