Thermal management based piston ring-cylinder liner low friction experimental system and use method thereof

An experimental system and piston ring technology, applied in the field of piston ring-cylinder liner low-friction experimental system, can solve the problems of small segmented samples, inability to reflect the spatial distribution of temperature, insufficient investigation of heat transfer, etc., and achieve low friction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

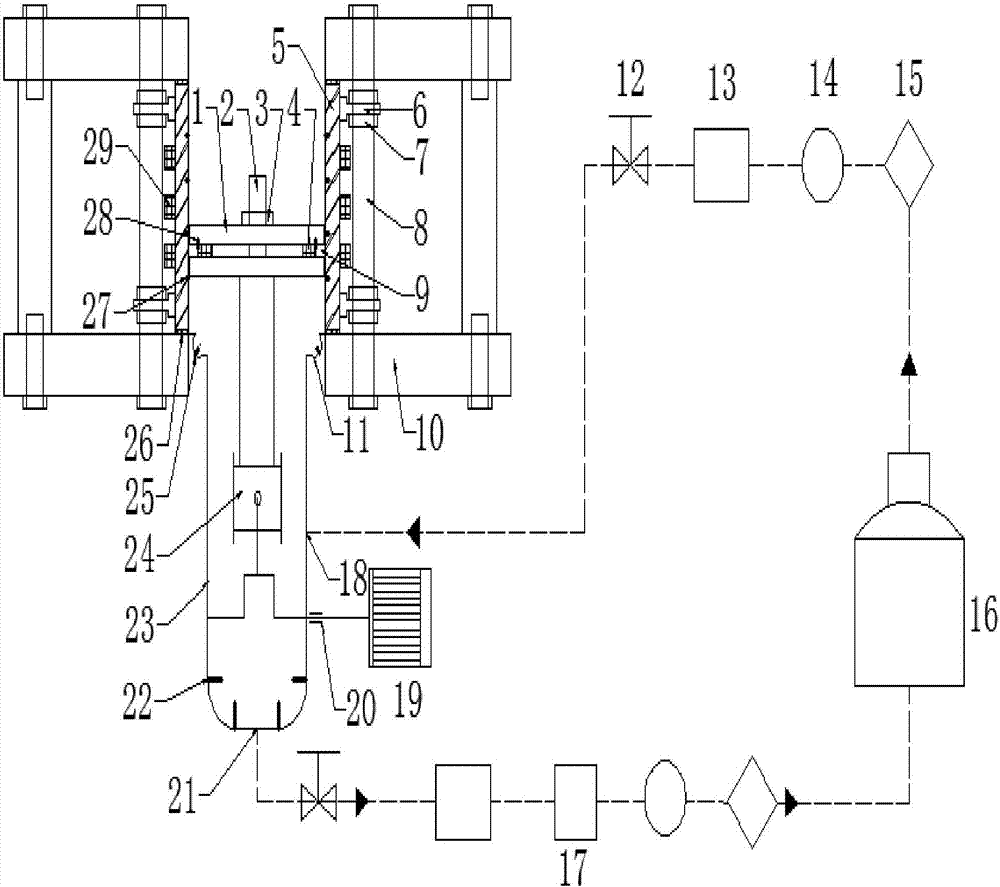

[0036] The piston ring-cylinder liner low-friction experimental system based on thermal management in this embodiment includes a cylinder liner fixing and heat transfer device for piston ring-cylinder liner fixing and heat transfer, a constant temperature lubricating oil circuit and a user for providing constant temperature lubricating oil for the system. The speed-regulating motor 19 used to drive the crank-connecting rod mechanism and the piston ring-cylinder liner parts;

[0037] The cylinder liner fixing and heat transfer device includes a longitudinal fixing plate 10, a clamp 1, a cylinder liner electric heater 29, a piston ring electric heater 4, a cylinder liner thermocouple 27, a piston ring thermocouple 28 and a radially elastic fixing ring 6 , a longitudinal fixing plate 10 is respectively arranged symmetrically on the left and right sides of the cylinder liner, and the cylinder liner 5 is fixed between the upper and lower inner surfaces of each longitudinal fixing pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com