Lithium ion battery photo frame filled with phase change material

A technology of lithium-ion batteries and phase-change materials, which is applied in the field of lithium-ion battery photo frames filled with phase-change materials, can solve the problems of large battery system vehicle space, reduced vehicle cruising range, and complex structure of battery photo frames, etc., to improve thermal management effect, improvement of thermal management performance, effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

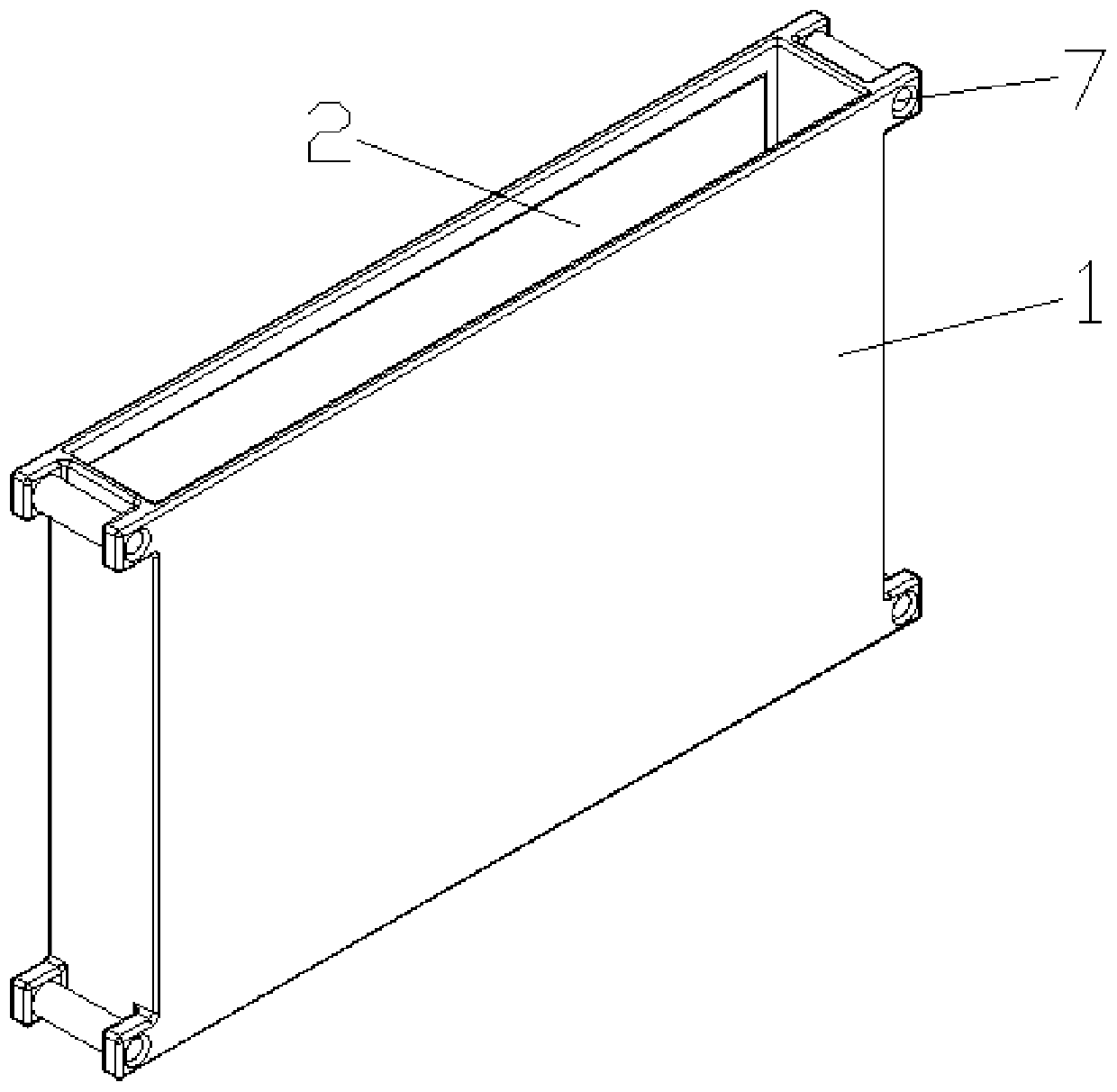

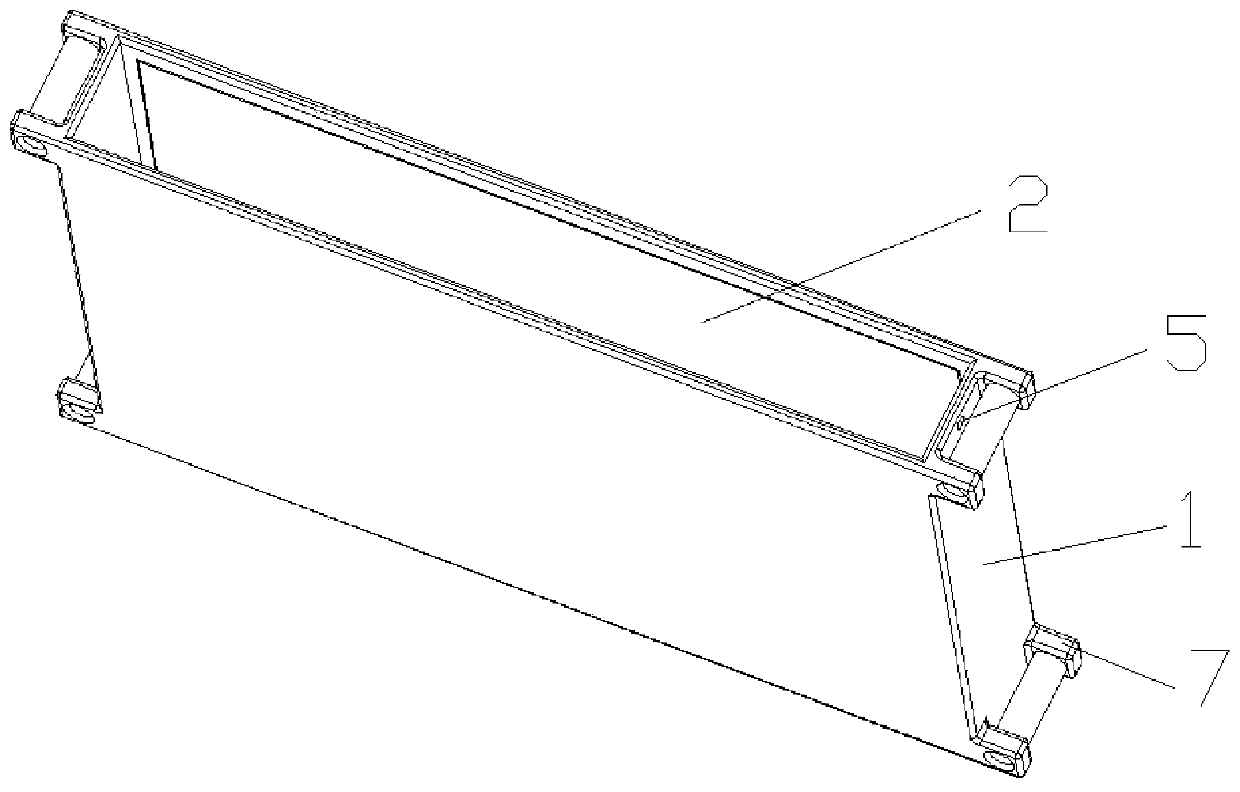

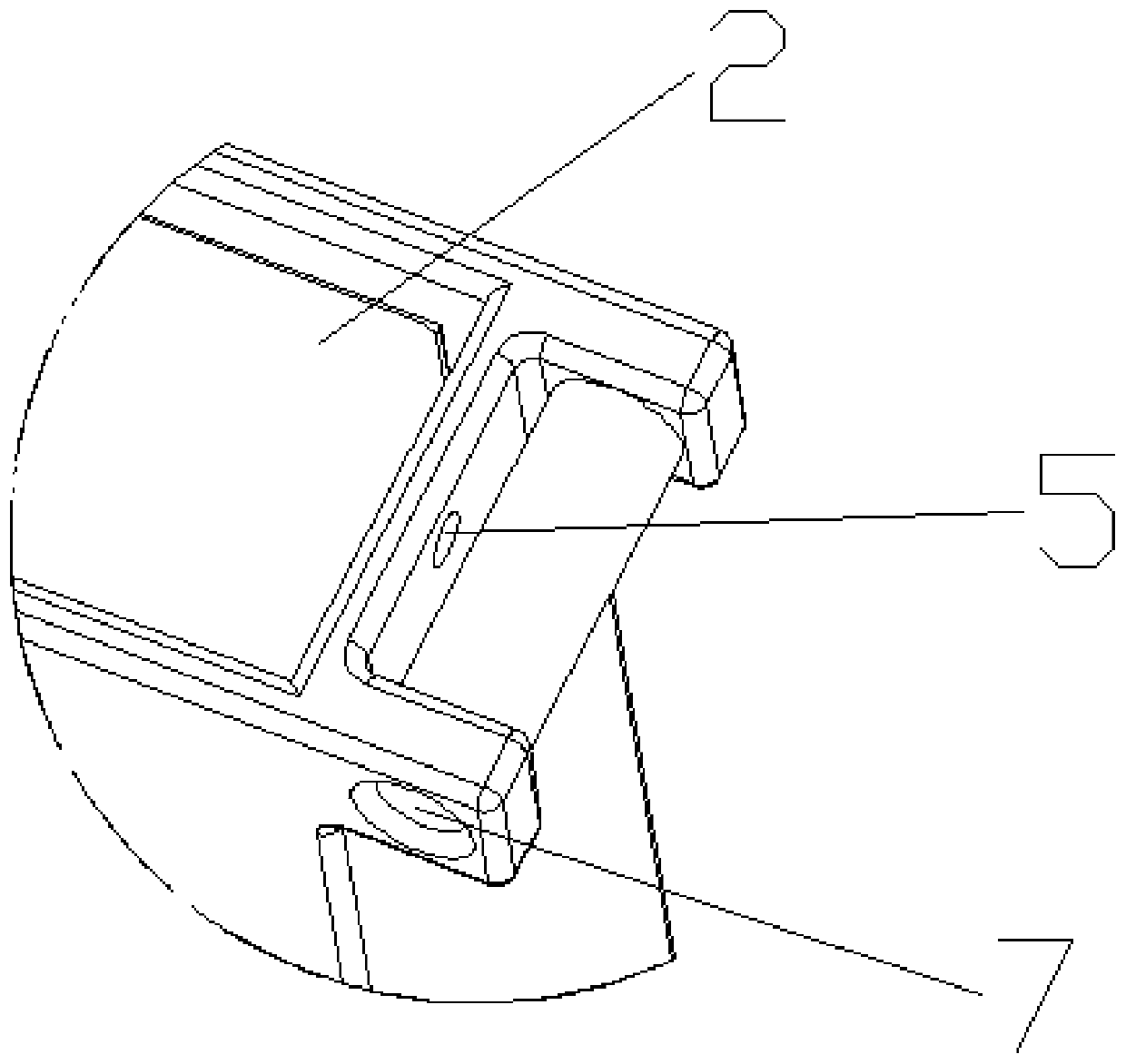

[0040] This embodiment provides a lithium-ion battery photo frame filled with phase-change materials, and its structure is detailed in the attached Figure 1-8 , shown in 12-14: including the photo frame body 1 that constitutes the photo frame module 6, the photo frame body 1 is provided with a battery cavity 2 for setting batteries and a phase change material filling cavity 3 filled with phase change materials. The phase-change material filling cavity 3 surrounds and is arranged outside the cell cavity 2 to cool the cells in the cell cavity 2. The phase-change material filling cavity 3 is provided with an exhaust hole 5 communicating with the outside for balancing internal and external pressures. An active surface of the photo frame body 1 for welding the battery lugs is open, and an aluminum sheet is arranged between the phase change material filling cavity 3 and the cell cavity 2 of a symmetrical active surface with the largest area of the photo frame body 1 4. The alumi...

Embodiment 2

[0050] This embodiment provides a lithium-ion battery photo frame filled with phase-change materials, and its structure is detailed in the attached Figure 9-14 As shown: it includes a photo frame body 1 that constitutes a photo frame module 6. The photo frame body 1 is provided with a battery cavity 2 for setting batteries and a phase change material filling cavity 3 filled with phase change materials. The phase change material filling cavity 3 Surrounding the outside of the cell cavity 2 to cool the cells in the cell cavity 2, the phase change material filling cavity 3 is provided with an exhaust hole 5 communicating with the outside to balance the internal and external pressure, the photo frame An active surface of the main body 1 for welding battery tabs is open, and an aluminum sheet 4 is provided between the phase-change material filling cavity 3 and the battery cavity 2 of a symmetrical active surface with the largest area of the photo frame body 1 . The aluminum shee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com