Method for mechanically prethinning cross section transmission electron microscope test sample

A technology of transmission electron microscopy and cross-section, which is applied in the direction of material analysis by measuring secondary emissions, and can solve problems such as sample loss, non-parallel pre-thinning success rate, sample grinding and perforation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

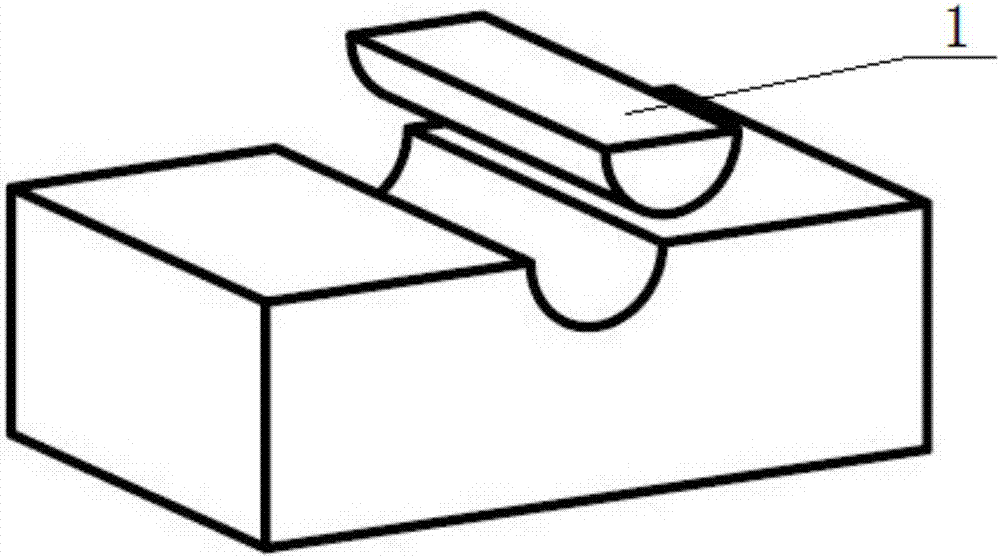

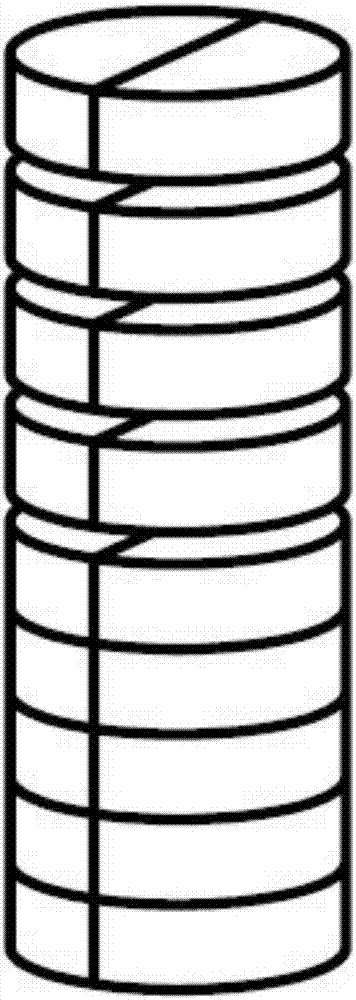

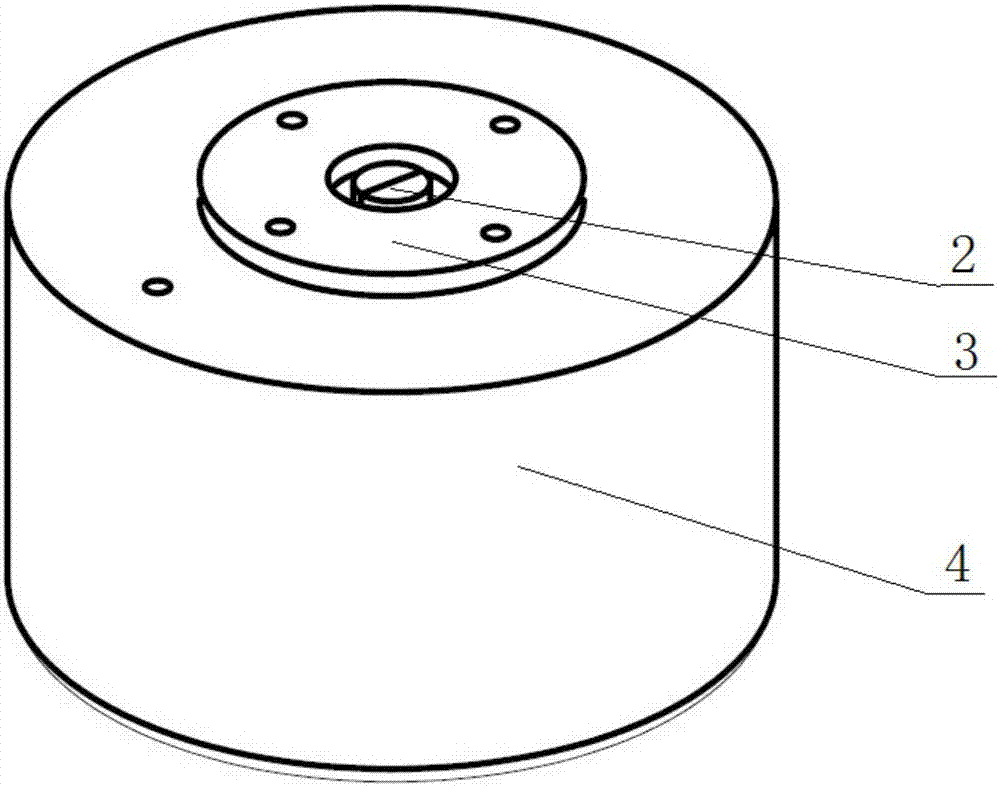

[0024] Such as figure 1 , figure 2 , image 3 , Figure 4 A mechanical pre-thinning method for a cross-sectional transmission electron microscope sample is shown, including a semicircular sample strip 1 with a diameter of 3 mm, a sample 2, a gasket 3, a stainless steel column 4, and a digital display dial indicator fixed on the base 5 , characterized by the following steps:

[0025] Step 1: Cut out a semicircular sample strip 1 with a diameter of 3mm from the sample by wire cutting, and heat and cure the two semicircular sample strips 1 with Gatan G2 resin. The curing temperature is 80-120°C and the curing time is 1 hour;

[0026] Step 2: Cut the sample strip with a diameter of 3mm after the resin is cured, and cut a sample 2 with a thickness of 0.8mm with a low-speed saw;

[0027] Step 3: Make a washer 3 with an outer diameter of 20mm, an inner diameter of 6mm, a thickness of 0.8mm, and a material of No. 45 steel;

[0028] Step 4: making a stainless steel cylinder 4 wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com