Integrated two-dimensional rotation flexible hinge

A technology of flexible hinges and rotating shafts, which is applied in the directions of instruments, installations, optics, etc., can solve the problems of motion accuracy requirements that cannot be used to control the bandwidth, the existence of starting friction torque, and low motion resolution, and achieve compact structure and no starting torque. , the effect of high motion resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] It will be described in detail below in conjunction with the accompanying drawings in order to better illustrate the structural features and functional features of the present invention, rather than limiting the protection scope of the present invention.

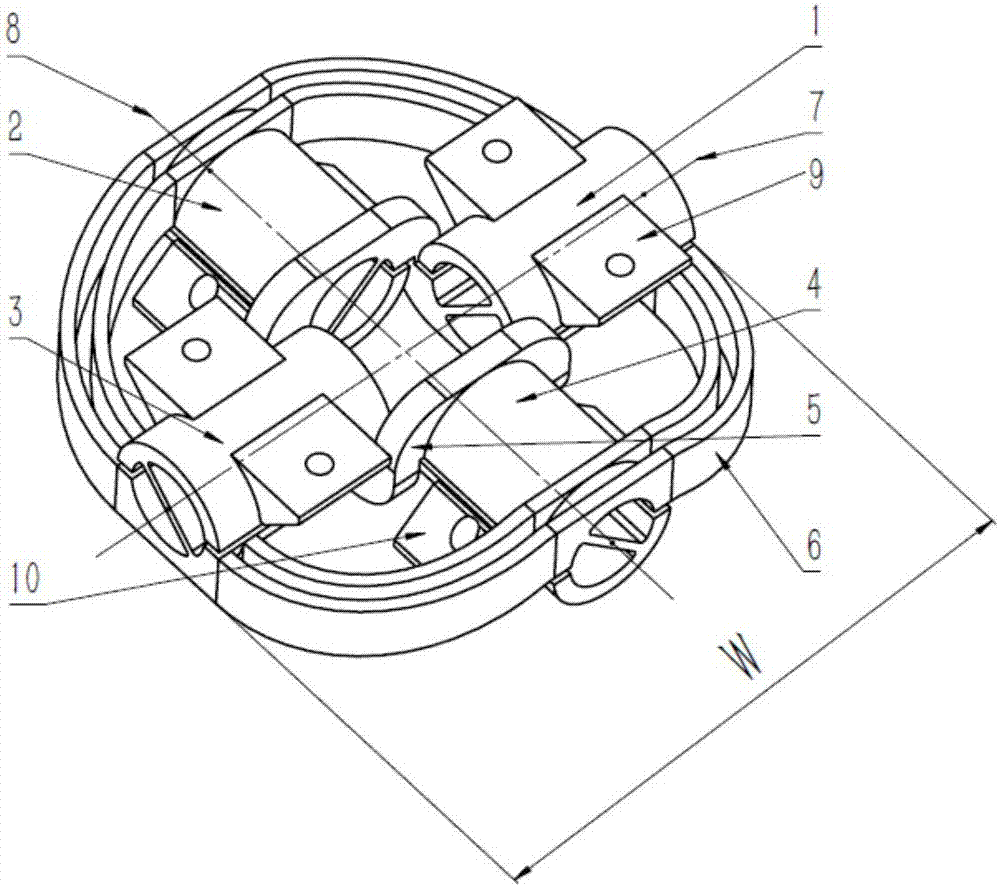

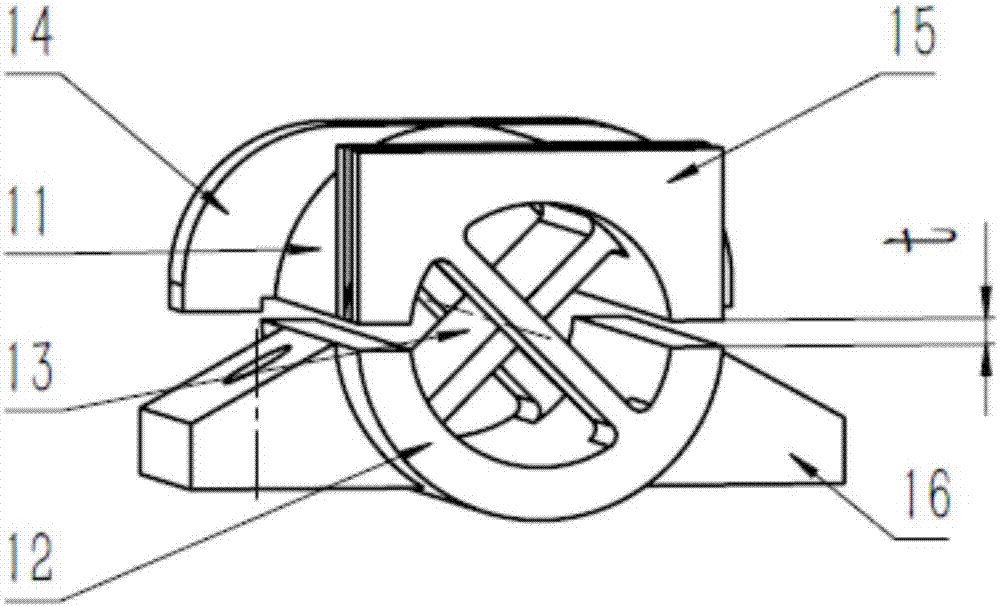

[0039] See attached figure 1 , the two-dimensional rotating flexible hinge of the present invention is composed of one part. Made using selective laser melting technology in 3D printing technology, the material is titanium alloy TC4. Tensile strength σ after processing b Between 1040MPa and 1100MPa, the yield strength σ 0.2 It is between 870MPa and 1030MPa, and the elastic modulus of the material is E=113GPa.

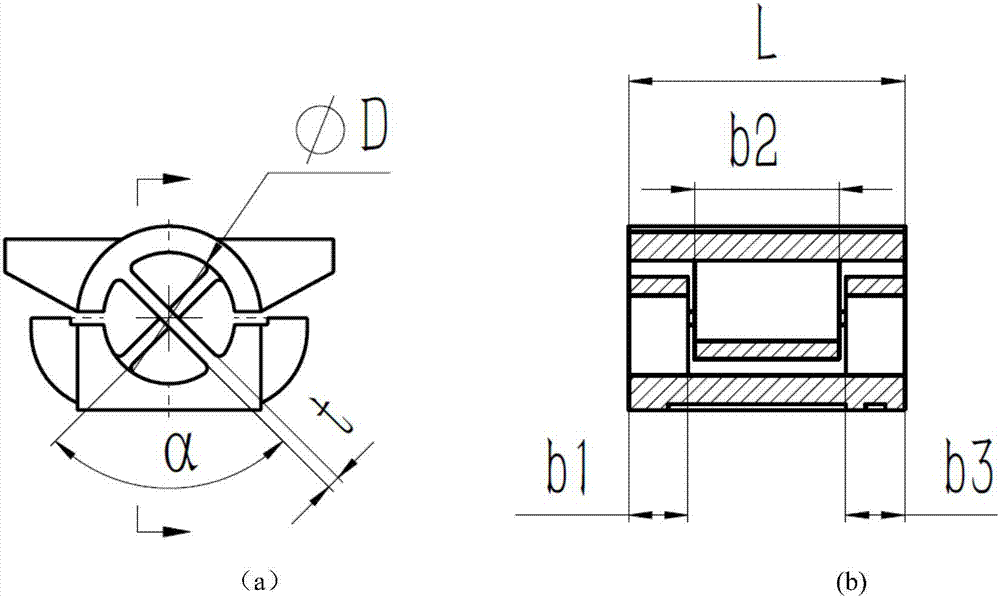

[0040] The torsional stiffness in the rotational dimension of the part can be estimated using the following formula:

[0041]

[0042]

[0043] The coefficient 2 means that two reed flexures arranged coaxially have the same cross reed parameters, E represents the elastic modulus of the material, D re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com