Ring compression type wireless electric energy transmission system suitable for automatic tool change of ultrasonic machining center

A technology of wireless power transmission and automatic tool change, applied in metal processing equipment, metal processing mechanical parts, circuits, etc. The effect of processing efficiency and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

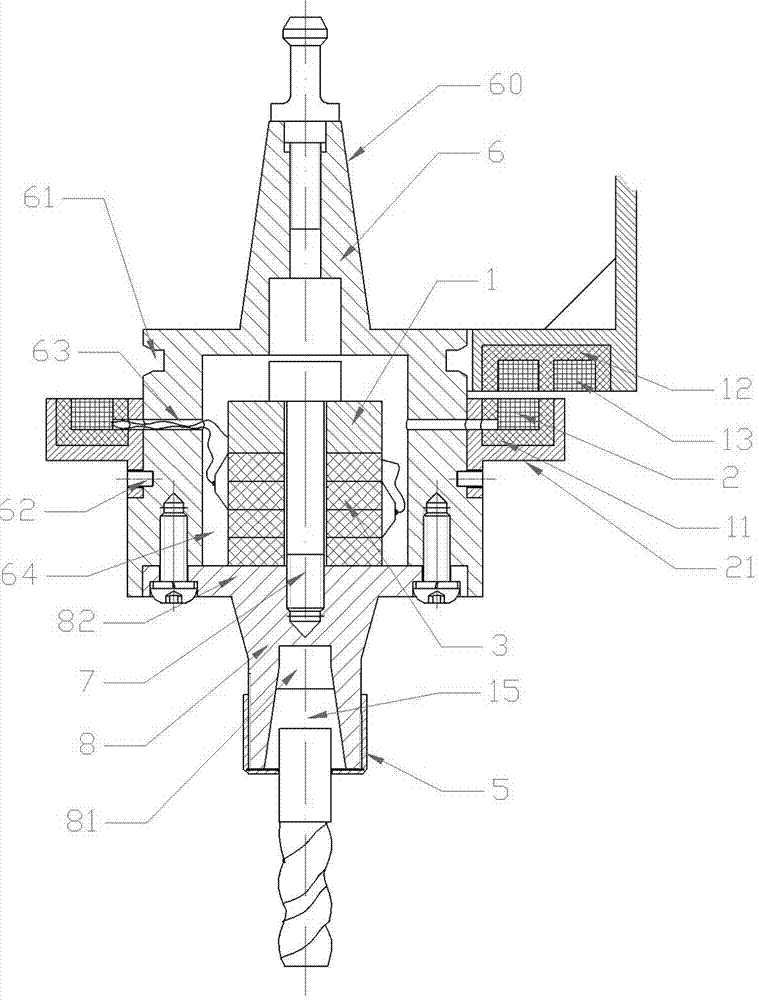

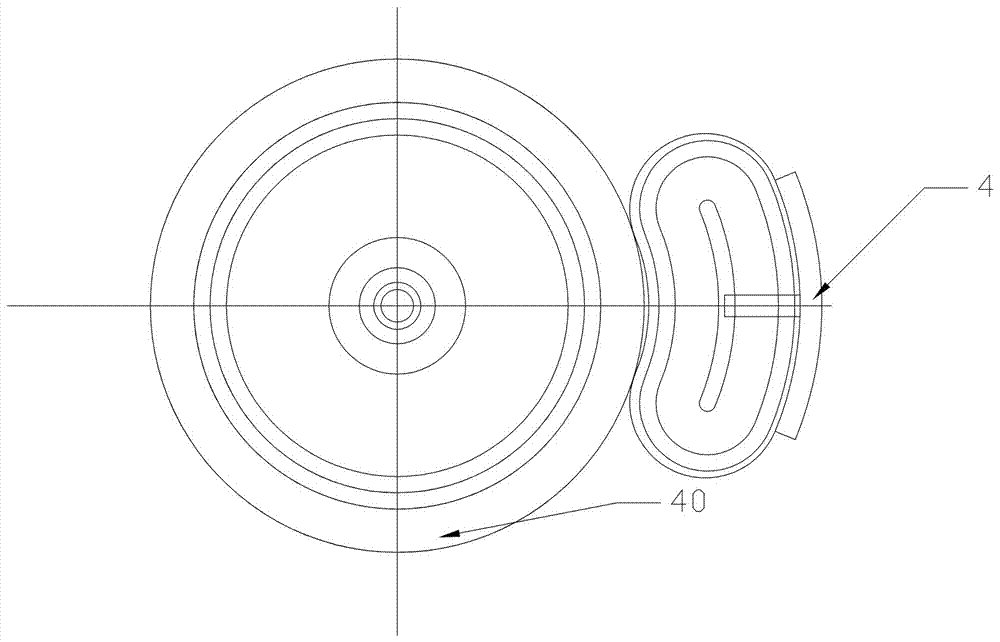

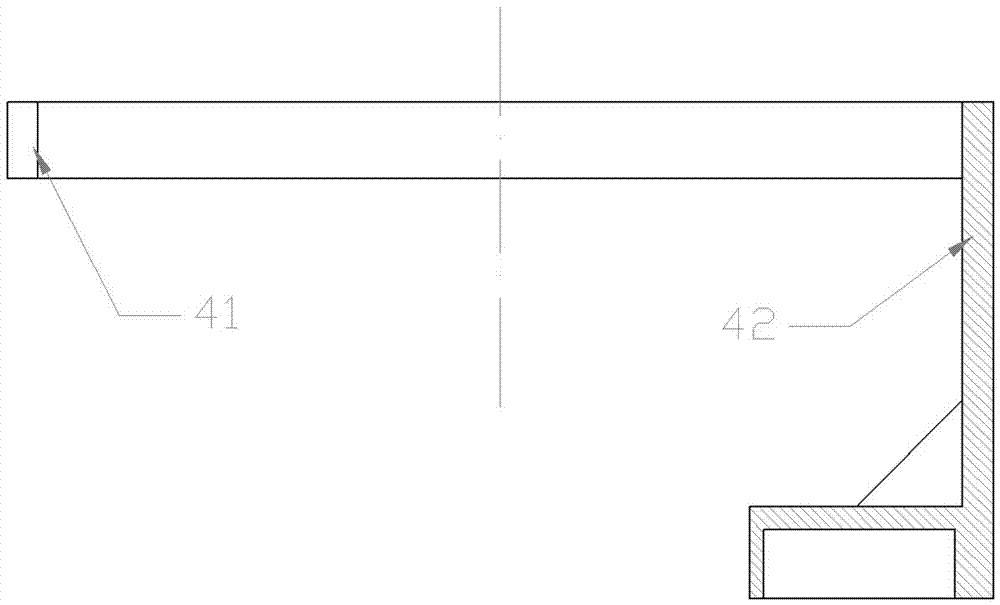

[0028] Example: see figure 1 , in the picture, 1-piezoelectric ceramic pressure plate, 2-disc-shaped power receiving coil, 3-piezoelectric ceramics, 4-quarter disc-shaped power transmitting coil support, 5-lock nut, 6-knife handle , 7-bolt, 8-horn, 11-disc ferrite, 12-quarter disc ferrite, 13-quarter disc power transmitting coil, 15-spring clip Head, 21-Disc-shaped power receiving part, 40-Ferrite fixed tank body, 41-Open ring, 42-Narrow fixed bracket, 60-Holding part, 61-Automatic tool change card slot, 62-Threaded hole, 63-lead hole, 64-cavity, 81-inner tapered hole, 82-flange.

[0029] A ring pressure wireless power transmission system suitable for automatic tool change in ultrasonic machining centers, including tool holder 6, piezoelectric ceramic plate 1, piezoelectric ceramic 3, horn 8, spring collet 15, and quarter disc shape Electric energy transmission coil 13, quarter disk-shaped ferrite 12, disk-shaped electric energy receiving coil 2, disk-shaped ferrite 11 and q...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com