Aluminum Profile Heavy Machining Center

A technology for machining centers and aluminum profiles, applied in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., can solve the problems of reducing processing efficiency and automation, limiting processing efficiency and accuracy, and less types of heavy-duty machining centers. To achieve the effect of reasonable design of positioning device, improvement of machining accuracy, and reasonable design of fixtures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the drawings.

[0027] Refer to figure 1 To Figure 8.

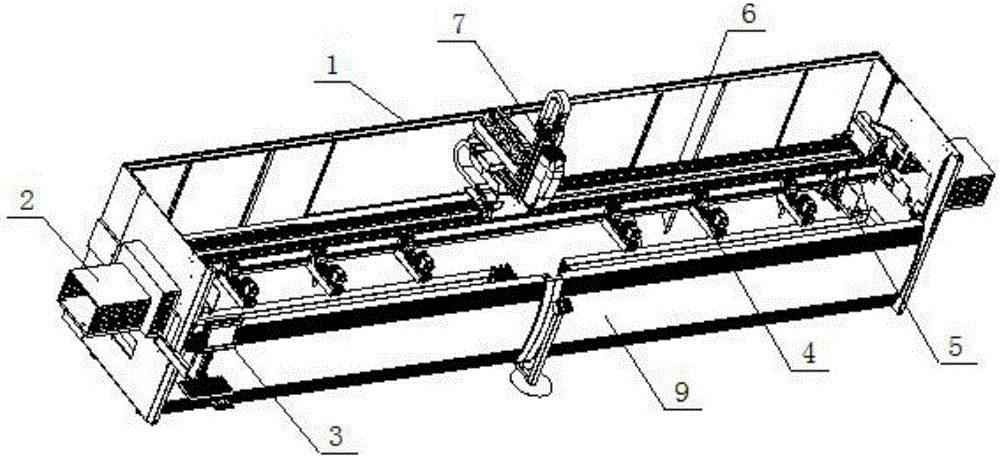

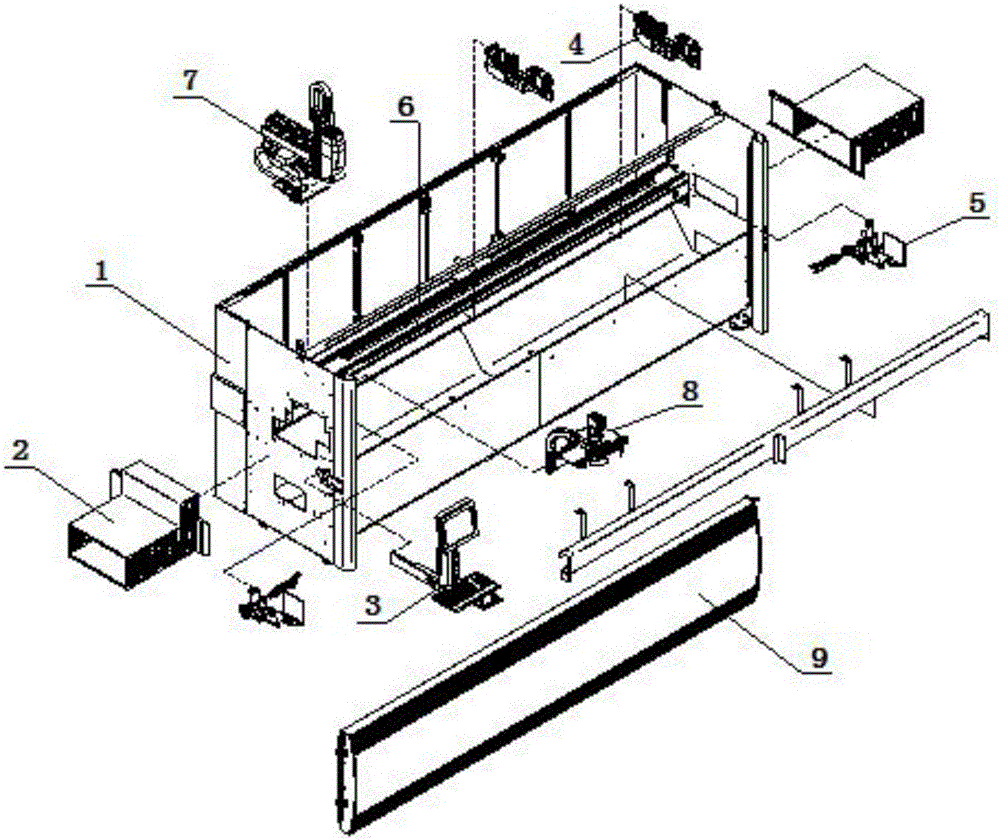

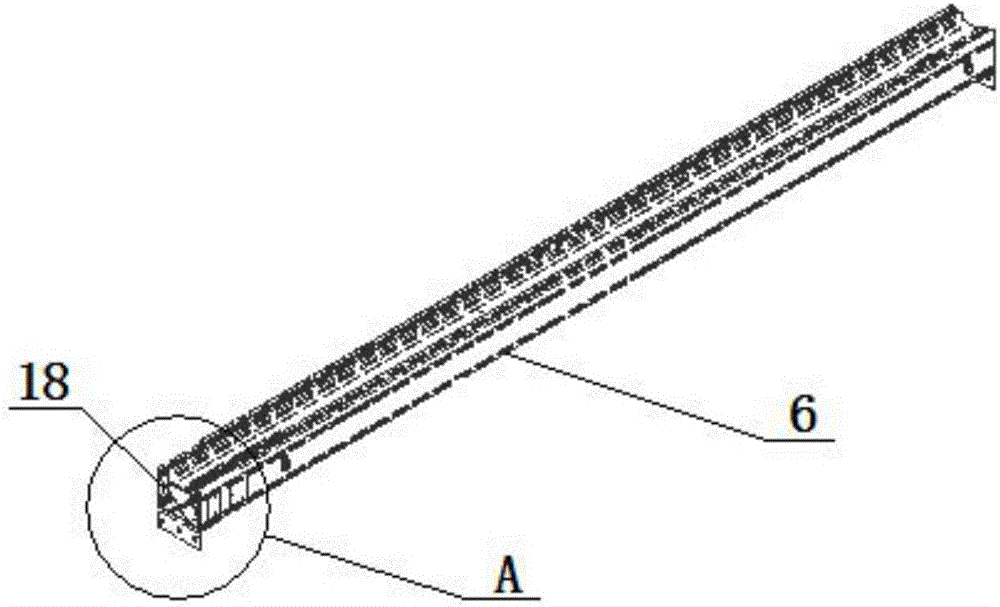

[0028] An aluminum profile heavy-duty machining center, including a fuselage body 1, the left and right sides and the rear side of the fuselage body 1 are provided with shells, and the front side of the fuselage body 1 is an open workbench. The outer side is provided with a PVC protective shell 9, the fuselage body 1 is provided with a feeding support structure 2 at both ends, the fuselage body 1 is provided with a cross beam 6 in the middle position, and the cross beam 6 connects the left and right sides of the fuselage body 1 Shell, the bottom of the beam 6 is provided with a support frame, the left end of the beam 6 is provided with a tool magazine 8 and a spindle portion 7 in sequence, a clamp 4 and a positioning device 5 are provided between the beam 6 and the body 1, so The number of the positioning device 5 is two, and a computer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com