Large multilayer penetration screening method and screening machine

A screening machine, screening and grading technology, applied in chemical instruments and methods, screening, solid separation, etc., can solve the unfavorable large-scale vibrating screen, multi-layer development, difficult bearing installation and replacement, small distance between forced synchronization, etc. problems, to achieve the effect of high screening efficiency, compact structure, and stable self-synchronization trajectory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

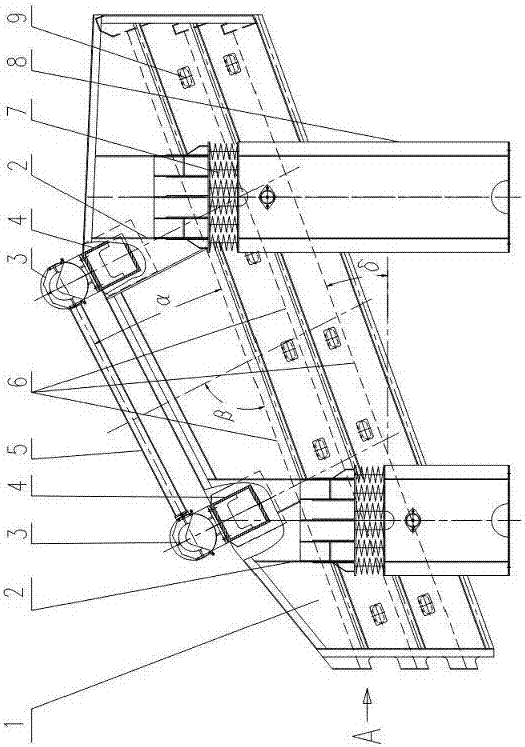

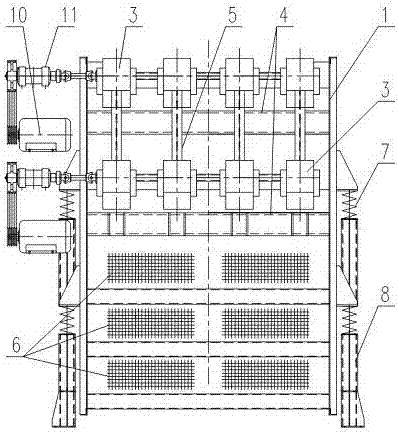

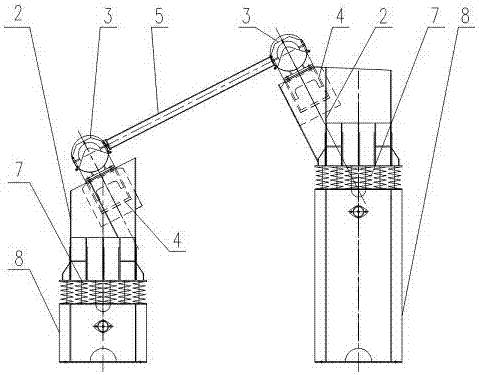

[0013] Embodiments of the present invention are described below in conjunction with the accompanying drawings: a large-scale multi-layer penetration screening method, which is characterized in that: the vibrating screen that uses the multi-layer screen surface in the screen frame to form a screen box, the inclination angle of each layer of screen surface and the horizontal plane The vibrator is two rows of single-axis box-type vibrators connected in series in parallel, with a large distance and self-synchronized operation, forming a linear vibration track with a resultant force. The angle between the resultant vibration line and the screen surface of each layer is 83°. The force direction of the material is nearly parallel to the axis of the sieve hole on the screen surface, so that the material is directly shot into the sieve hole of the screen surface; the material to be classified is placed in a screen box with multiple screen surfaces, and the material is on each layer of sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com