Four-degree-of-freedom double-push cylinder-type welding robot

A technology of welding robot and degree of freedom, which is applied in the field of machinery, can solve the problems of heavy robot arm, poor mechanism dynamic performance, joint error accumulation, etc., and achieve the effect of overcoming low overall rigidity, large space occupation and compact transmission structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

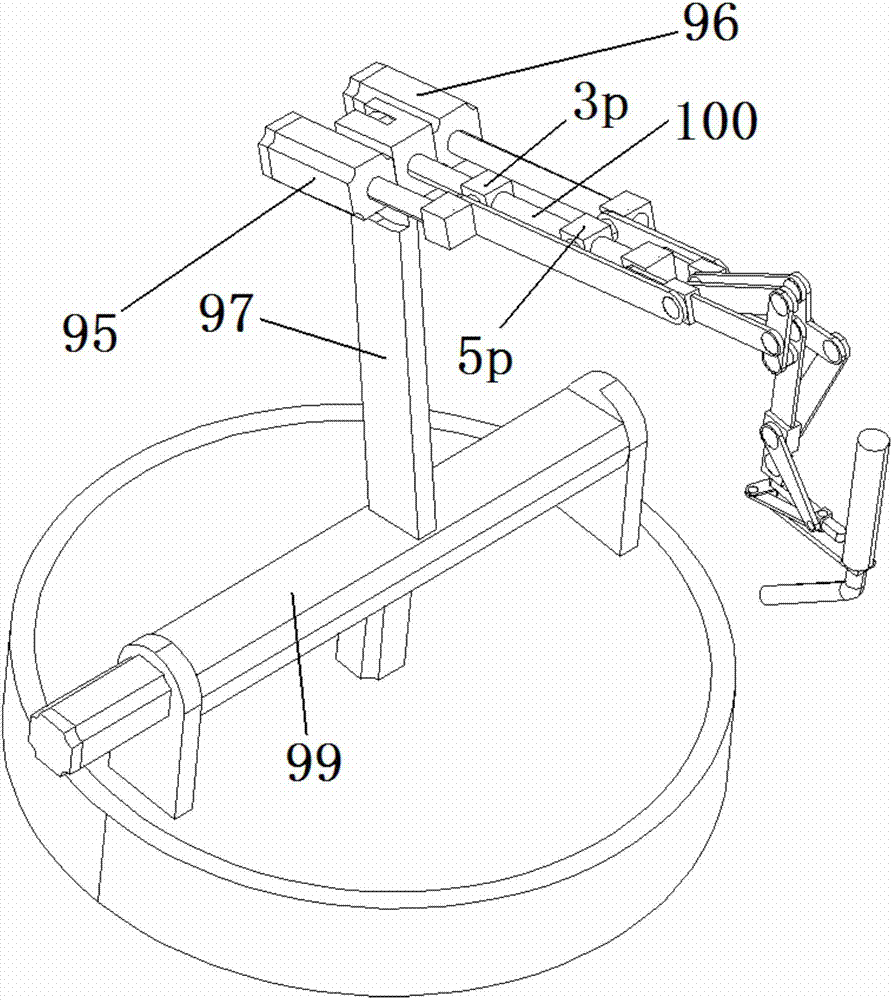

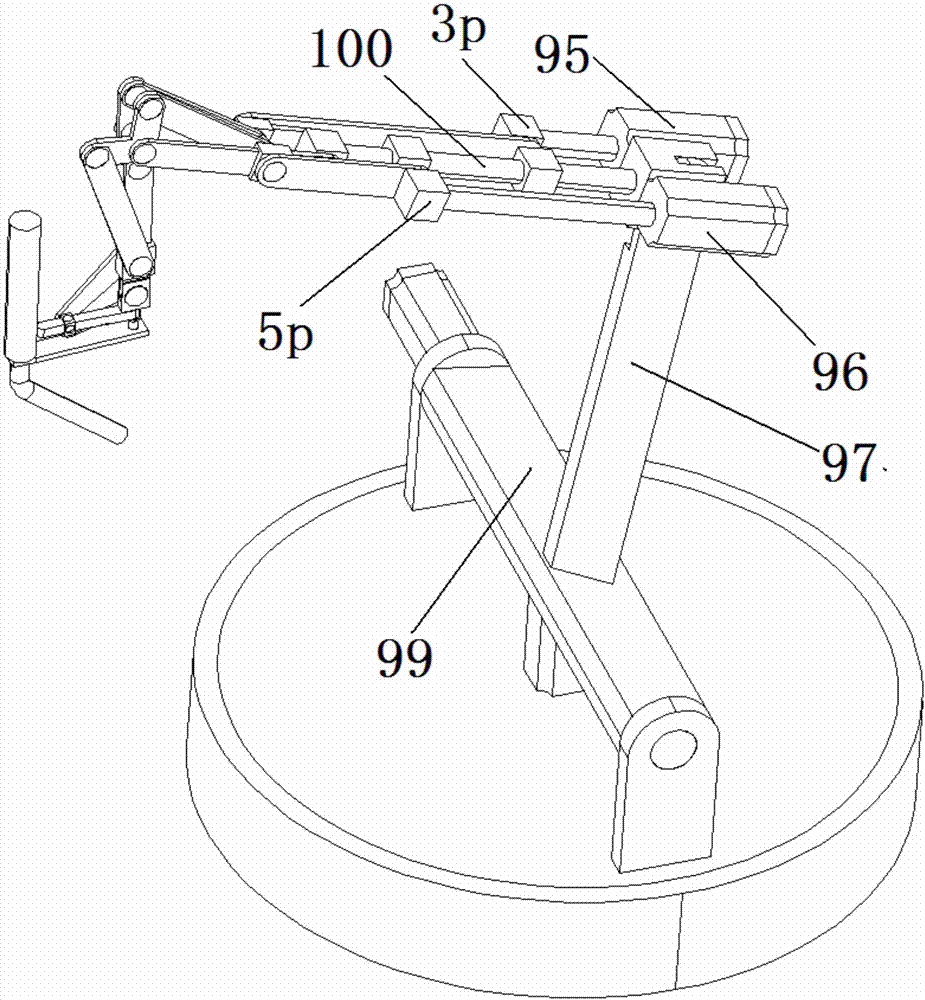

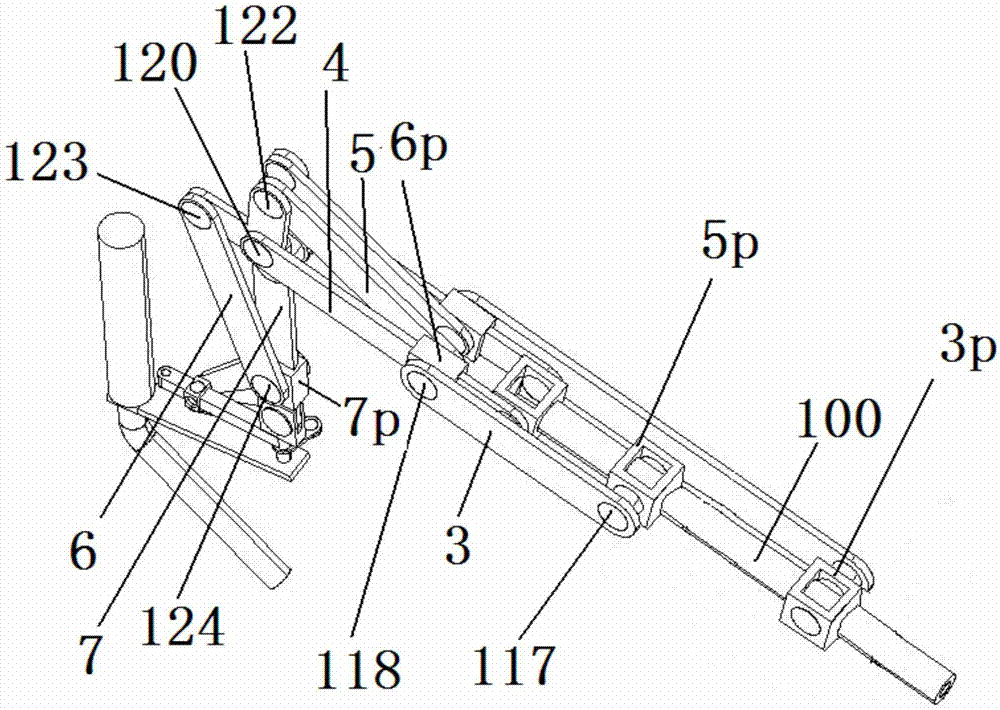

[0069]A four-degree-of-freedom double-push cylinder type welding robot, including a small arm 100, a frame 99, an actuator 98, a support rod 97, a guide rod 2q, a first electric push rod 96, a second electric push rod 95, a third slide Sleeve 3p, fifth sliding sleeve 5p, sixth sliding sleeve 6p, seventh sliding sleeve 7p, eighth sliding sleeve 8p, ninth sliding sleeve 9p, third connecting rod 3, fourth connecting rod 4, fifth connecting rod 5 , the sixth connecting rod 6, the seventh connecting rod 7, the eighth connecting rod 8, the ninth connecting rod 9, the tenth connecting rod 10, the eleventh connecting rod 11, the twelfth connecting rod 12, the thirteenth connecting rod 13. The fourteenth connecting rod 14 and the fifteenth connecting rod 15,

[0070] The specific structure and connection relationship are as follows:

[0071] Such as figure 1 and 2 Shown:

[0072] One end of the small arm 100 is connected to the upper end of the support rod 97 through the rotating j...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com