Shape-preserving and positioning tool for composite wing wallboard

A composite material, positioning tooling technology, applied in aircraft assembly, aircraft parts, ground installations, etc., can solve problems such as increased operational complexity, deformation of wing panels, damage to support points, etc., to improve assembly quality and uniform external force distribution. , The effect of preventing stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

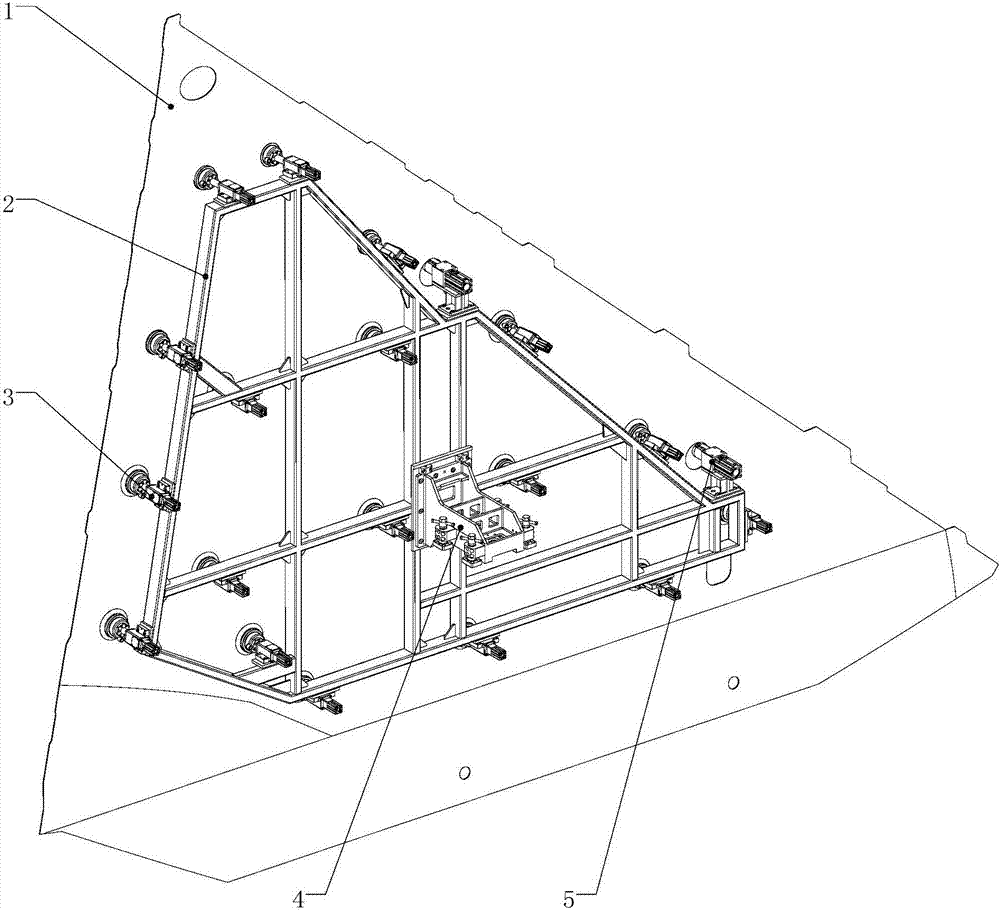

[0043] Such as Figure 1~4 As shown, the conformal positioning tool for the composite wing panel of this embodiment includes: conformal frame 2 , telescopic suction cup assembly 3 , transition support joint 4 and adaptive support assembly 5 .

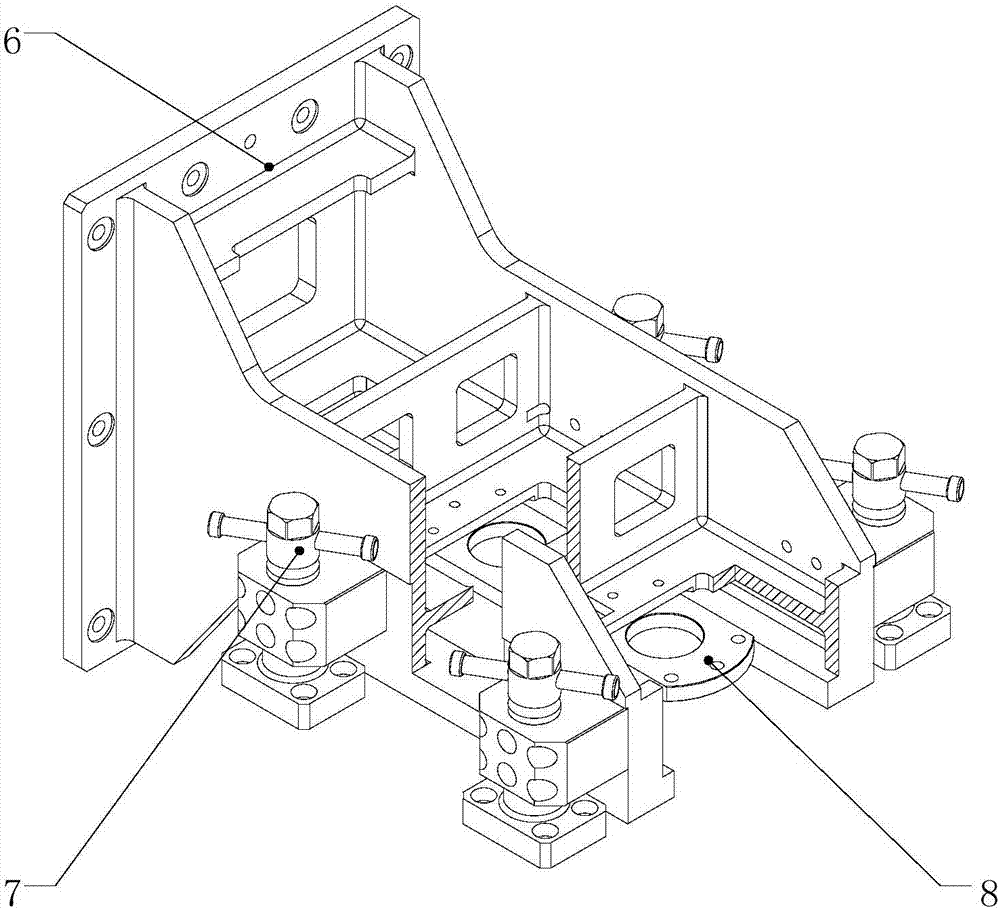

[0044] The transition support joint 4 includes: a support mounting seat 6, a locking bolt assembly 7 and a positioning seat 8, which are used for joint connection with a wing panel decomposition / fitting machine tool.

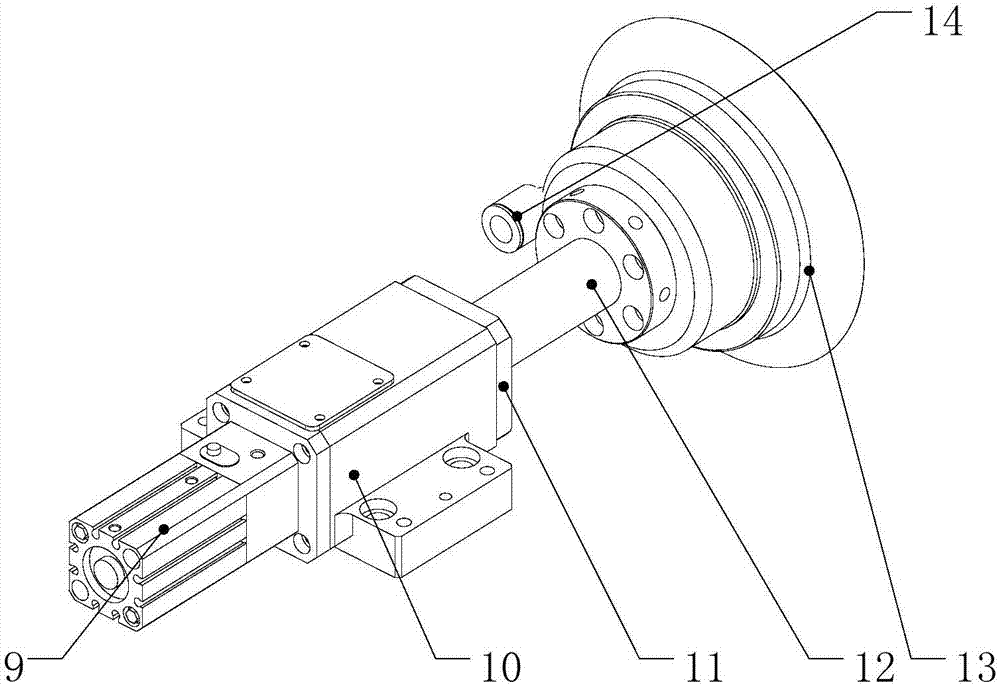

[0045] The telescopic suction cup assembly 3 comprises a suction cup locking cylinder 9, a suction cup assembly mount 10, a ball guide bush 11, a telescopic connecting rod 12, a vacuum suction cup 13 and an air pipe joint 14, and is used to realize vacuum adsorption and fixation of the wing panel 1.

[0046] The adaptive support assembly 5 includes a mounting seat 15, a support locking cylinder 16 as a driving mechanism, a mounting bracket 17, a push block with a wedge 18 at the end, an end cover 19, a movable support cla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com