Welding type metallurgy slag pot without bolt connection and manufacturing method of welding type metallurgy slag pot

A manufacturing method and a technology without bolts, applied to welding equipment, furnace types, manufacturing tools, etc., can solve the problems of increased costs, short life of casting slag pots, and reduced manufacturing costs of welded structure slag pots, so as to simplify cost input, The effect of saving costs and saving national economic costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

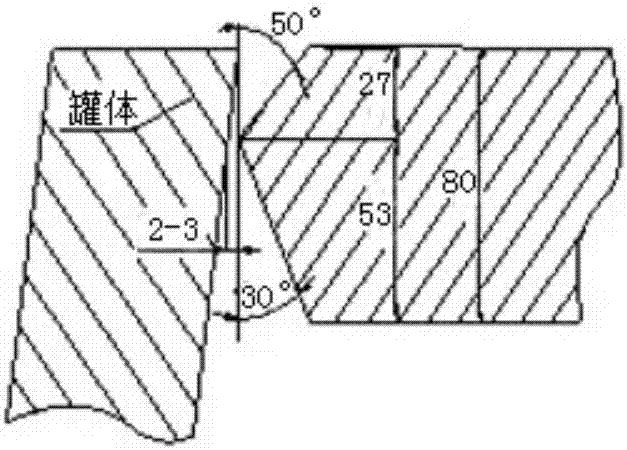

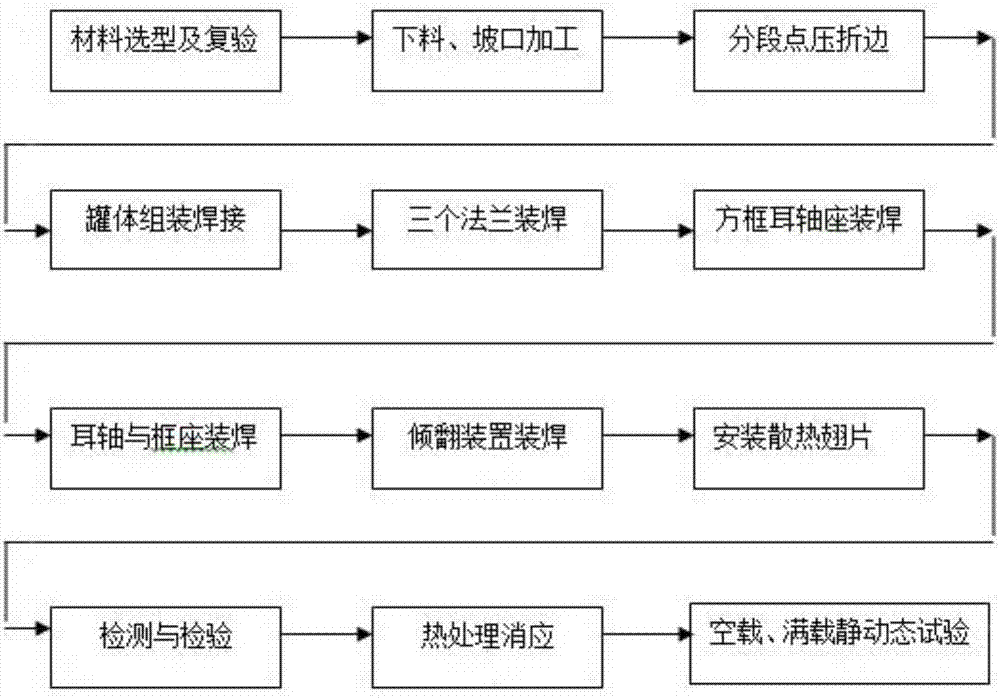

[0126] First, the square frame trunnion seat design. After the main body of the slag tank is manufactured, a square frame-shaped trunnion seat (centralized restraint frame) is designed in the central area of the trunnion axis at the two ends of the tank body. Inside the square frame-shaped trunnion seat, there are four groups of 8 steel plates in total, upper, lower, left, and right, together with the trunnion to form the overall force-bearing structure of the square frame-shaped trunnion seat. Depending on the working conditions, the outer surface of the rib plate in the four directions of up, down, left, and right can be welded with a surface cover plate, and the total number of cover plates can be 4 to 8 pieces. All adopt symmetrical welding and are double-number symmetrical rib structure.

[0127] Second, the structural design of the three flange rings. Three flange rings are respectively designed on the tank mouth, the tank waist and the lower part of the waist of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com