Comfortable and natural type OPTIM fiber, pima cotton, real silk and cashmere mixture knitting yarn knitted fabric structure

A technology of knitted fabrics and blended yarns, applied in knitting, fiber treatment, weft knitting, etc., can solve the problems of expensive, hard, easy to fluff, etc., and achieve the effect of simple preparation method, improved durability, and soft luster

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

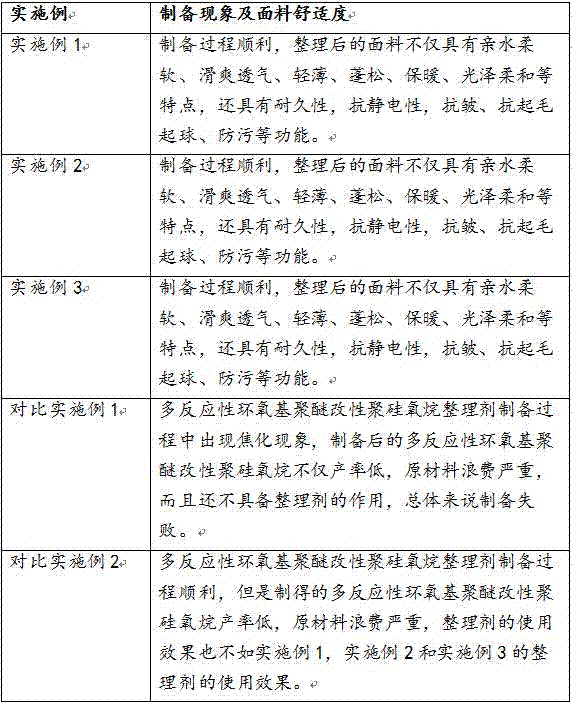

Embodiment 1

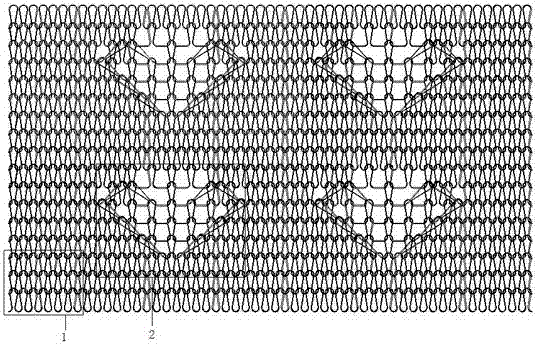

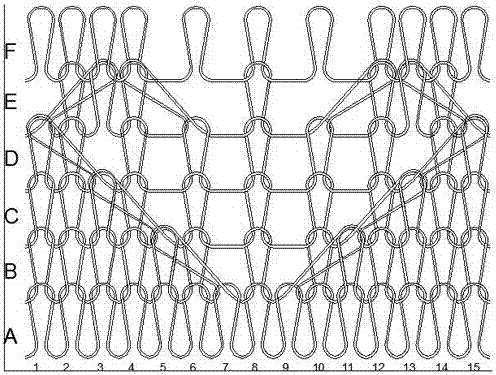

[0042] Such as figure 1 and figure 2 As shown, the knitted fabric structure of comfortable natural OPTIM fiber, pima cotton, silk and cashmere blended yarn includes basic weave 1 and leno weave 2. Leno weave 2 includes multiple independent units, and each independent unit includes A, B, C, D, E, F six rows, fifteen columns, A, B, C, D, E, F six rows, each row corresponds to a yarn;

[0043] The A course and B course consisted of fifteen stitches, the C course consisted of thirteen stitches, and the D, E and F courses contained eleven stitches.

[0044] This scheme adopts the pattern structure design combined with two-way transfer, and uses different fiber raw materials for multi-component blending, which can make full use of the advantages of various fibers and realize the complementarity of their performance. New multicomponent yarns and fabrics with unique performance and appearance provide the basis. The structure of comfortable natural OPTIM fiber, pima cotton, real si...

Embodiment 2

[0070] Embodiment 2 is the same as Embodiment 1, and the difference is:

[0071] The multi-reactive epoxy polyether modified polysiloxane finishing agent comprises the following components and their parts by weight:

[0072] 800 parts by weight of polyreactive epoxy polyether

[0073] Polysiloxane 600 parts by weight

[0074] 0.16 parts by weight of chloroplatinic acid

[0075] Octoxynol 60 parts by weight

[0076] The preparation method of polyreactive epoxy polyether modified polysiloxane finishing agent comprises the following steps:

[0077] (10) Weigh the polyreactive epoxy polyether in parts by weight, add it into the reaction kettle, heat it at 13°C per hour to 55°C, and feed nitrogen;

[0078] (20) Weigh polysiloxane and chloroplatinic acid in parts by weight, add them into the reaction kettle, start stirring, continue heating, and heat to 80°C at a rate of 7°C per hour, and keep warm for 6h;

[0079] (30) Cool down the reactor at 18°C / h, then weigh octoxynol by w...

Embodiment 3

[0087] Embodiment 3 is the same as Embodiment 1, and the difference is:

[0088] The multi-reactive epoxy polyether modified polysiloxane finishing agent comprises the following components and their parts by weight:

[0089] 1000 parts by weight of polyreactive epoxy polyether

[0090] Polysiloxane 800 parts by weight

[0091] 0.2 parts by weight of chloroplatinic acid

[0092] Octoxynol 100 parts by weight

[0093] The preparation method of polyreactive epoxy polyether modified polysiloxane finishing agent comprises the following steps:

[0094] (10) Weigh the multi-reactive epoxy-based polyether by weight, add it to the reaction kettle, heat it at 15°C per hour to 60°C, and feed nitrogen;

[0095] (20) Weigh polysiloxane and chloroplatinic acid in parts by weight, add them to the reaction kettle, start stirring, continue heating, and heat to 90°C at a rate of 10°C per hour, and keep warm for 7h;

[0096] (30) Lower the temperature of the reactor at 15°C / h, then weigh oc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com