Wheel train energy storage power generation device

A power generation device and energy storage technology, which is applied in the direction of transmission, engine, machine/engine, etc., can solve the problems of only 120km/h maximum speed, reduced driving torque, unsuitable for electric vehicles, etc., to reduce heat, prolong life, improve The effect of high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

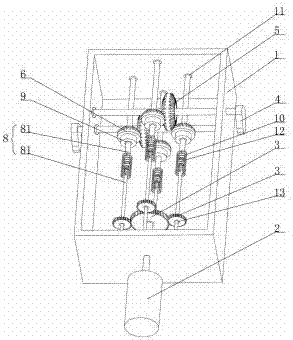

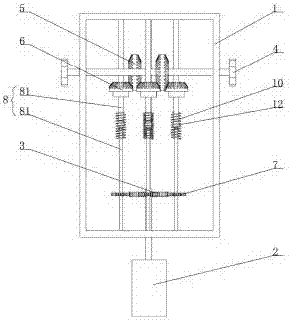

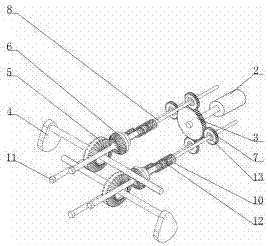

[0023] like Figure 1-4 As shown, a gear train energy storage power generation device includes a gearbox body 1, a generator 2 connected to the gearbox body 1, and a drive assembly is arranged in the gearbox body 1, including an eccentric weight 4, a disk gear 5, a cone Shaped gear 6 and driven gear 7, the eccentric weight 4 is coaxially connected with the disk gear 5, the front and back sides of the disk gear 5 are provided with teeth, and the front and back sides of the disk gear 5 are meshed with a bevel gear 6, the cone The gear 6 is coaxially connected with the driven gear 7 through the rotating shaft 8, and the driven gear 7 is meshed with the power generation gear 3. The power generation gear 3 is installed on the main shaft of the generator 2, and the bevel gear 6 has a built-in one-way lock with the same locking direction. Bearing one 9 and one-way bearing one 9 are set on the corresponding rotating shaft 8, a cavity 401 is arranged in the eccentric weight 4, and a ro...

Embodiment 2

[0034] like Figure 1-4 As shown, a gear train energy storage power generation device includes a gearbox body 1, a generator 2 connected to the gearbox body 1, and a drive assembly is arranged in the gearbox body 1. There are two sets of drive assemblies, and the two sets of drive assemblies are in the form of Relatively arranged, including eccentric weight 4, disk gear 5, bevel gear 6 and driven gear 7, the eccentric weight 4 is coaxially connected with the disk gear 5, the front and back of the disk gear 5 are provided with teeth, the disk gear 5 There are bevel gears 6 meshed on the positive and negative sides of the shaft, and the bevel gears 6 are coaxially connected with the driven gears 7 through the rotating shaft 8. The driven gears 7 are meshed with the generator gears 3, and the generator gears 3 are installed on the main shaft of the generator 2. , the bevel gears 6 have built-in one-way bearings-9 with the same locking direction, and the one-way bearings-9 are sle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com