Fuel injector needle valve displacement curve prediction method for jerk fuel injection system

A technology of fuel injection system and displacement curve, which is applied in the field of prediction of needle valve displacement curve of injector in pulsating fuel injection system, to achieve the effects of convenient combustion analysis, solving installation difficulties and simple working principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

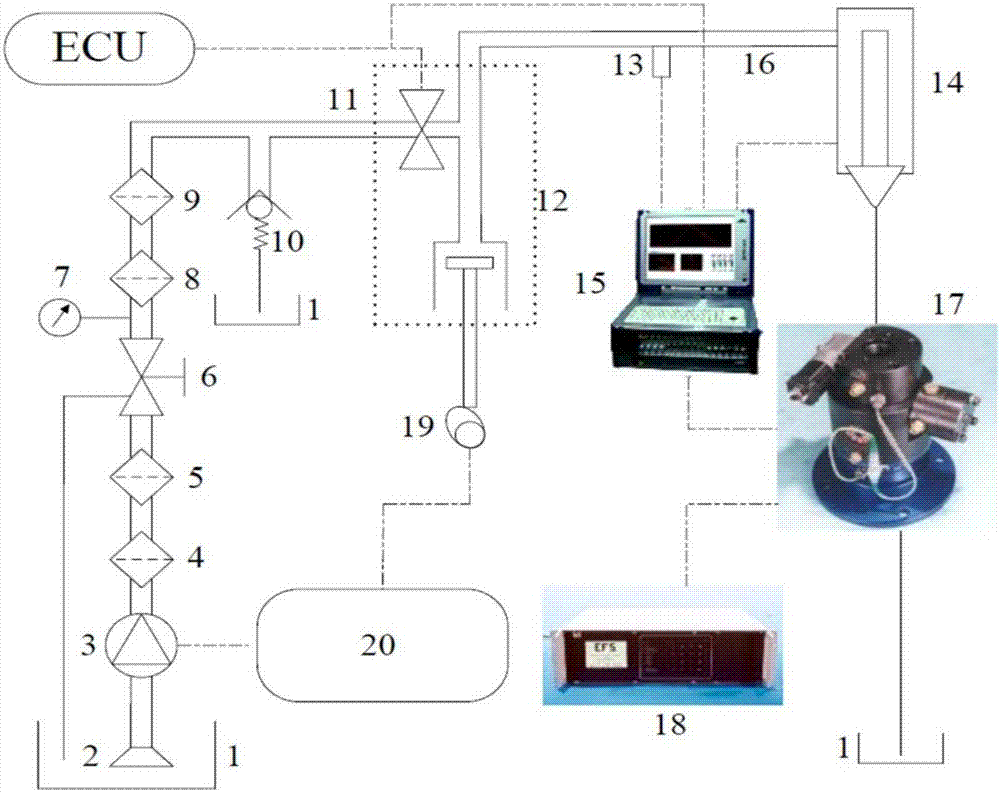

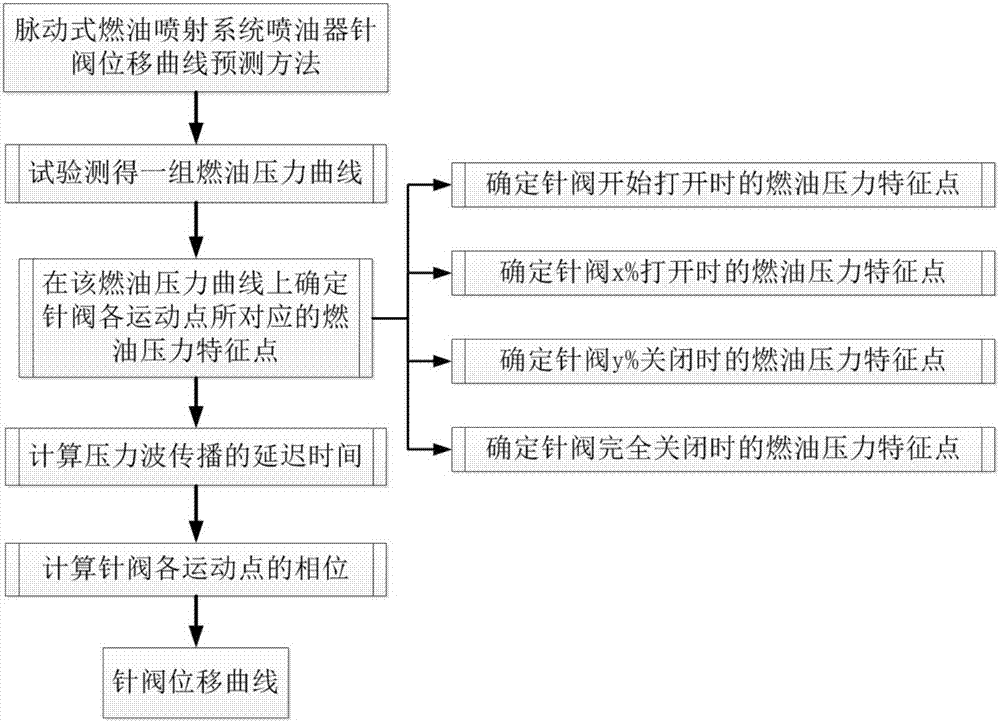

[0025] The present invention will be described in detail below with reference to the accompanying drawings and examples.

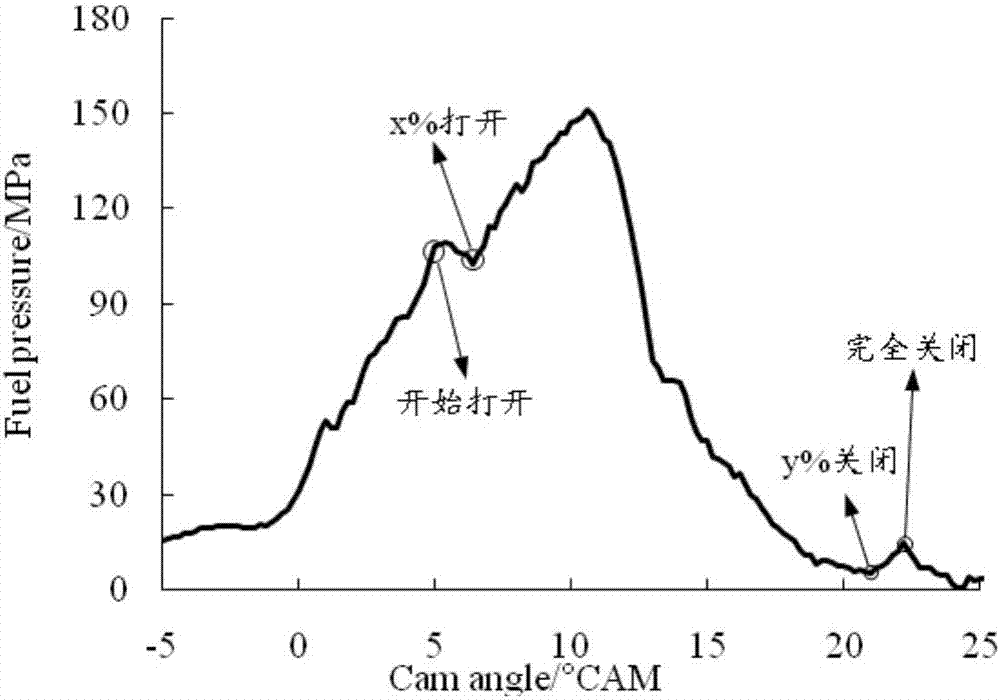

[0026] The motion state of the injector needle valve mainly includes two steady states of normally closed and normally open, and two transient states of open and closed. When the needle valve is normally closed and normally open, its displacement is 0 and the maximum lift respectively, so the key is to determine the phase and displacement corresponding to the two transient states of the needle valve opening and closing. Since the time it takes for the needle valve to open and close is extremely short, it can be assumed that both opening and closing are a constant speed process. In addition, the maximum lift of the needle valve is known and can be provided by the manufacturer. Therefore, it is only necessary to determine the phases when the needle valve begins to open, x% open, y% close, and fully closed, and then calculate the delay of the pressure wave t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com