Failure effect assessment dimension optimization method based on discriminability coefficient

A discriminating and dimensional technology, applied in data processing applications, instruments, resources, etc., can solve problems such as poor consideration, deviation of final results, and lack of systematic scientific theoretical basis for dimension selection, so as to ensure completeness and enhance responsibility. effect of consciousness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

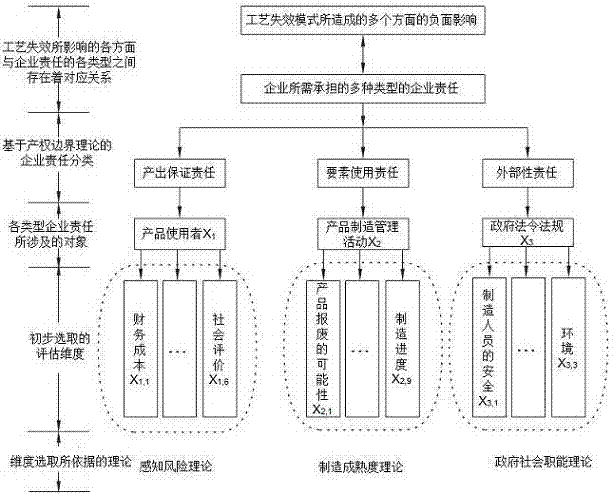

[0027] The present invention will be further described below in conjunction with drawings and embodiments. see figure 1 , the dimension optimization method of failure impact assessment based on discrimination coefficient, the implementation steps are as follows:

[0028] (1) According to the corresponding relationship between the aspects involved in the impact of process failure and the types of corporate responsibility, according to the theory of property rights boundary, perceived risk theory and manufacturing maturity theory, a systematic theoretical basis and completeness of manufacturing process failure are constructed Severity assessment dimension system, see figure 1 , Table 1, Table 2 and Table 3;

[0029] Table 1 Severity evaluation dimension X for product users 1

[0030]

[0031] Table 2 Severity assessment dimension X for product manufacturing management activities 2

[0032]

[0033] Table 3 Severity assessment dimension X for government laws and regul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com