Halogen-free low-smoke flame-retardant cross-linked polyolefin insulated environmental protection cable

A low-smoke, flame-retardant, cross-linked technology, which is applied in the direction of insulated cables, insulated conductors, organic insulators, etc., can solve the problems of long-distance cable damage, reduce the contact area, ensure the water-blocking effect, and increase the flame-retardant effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

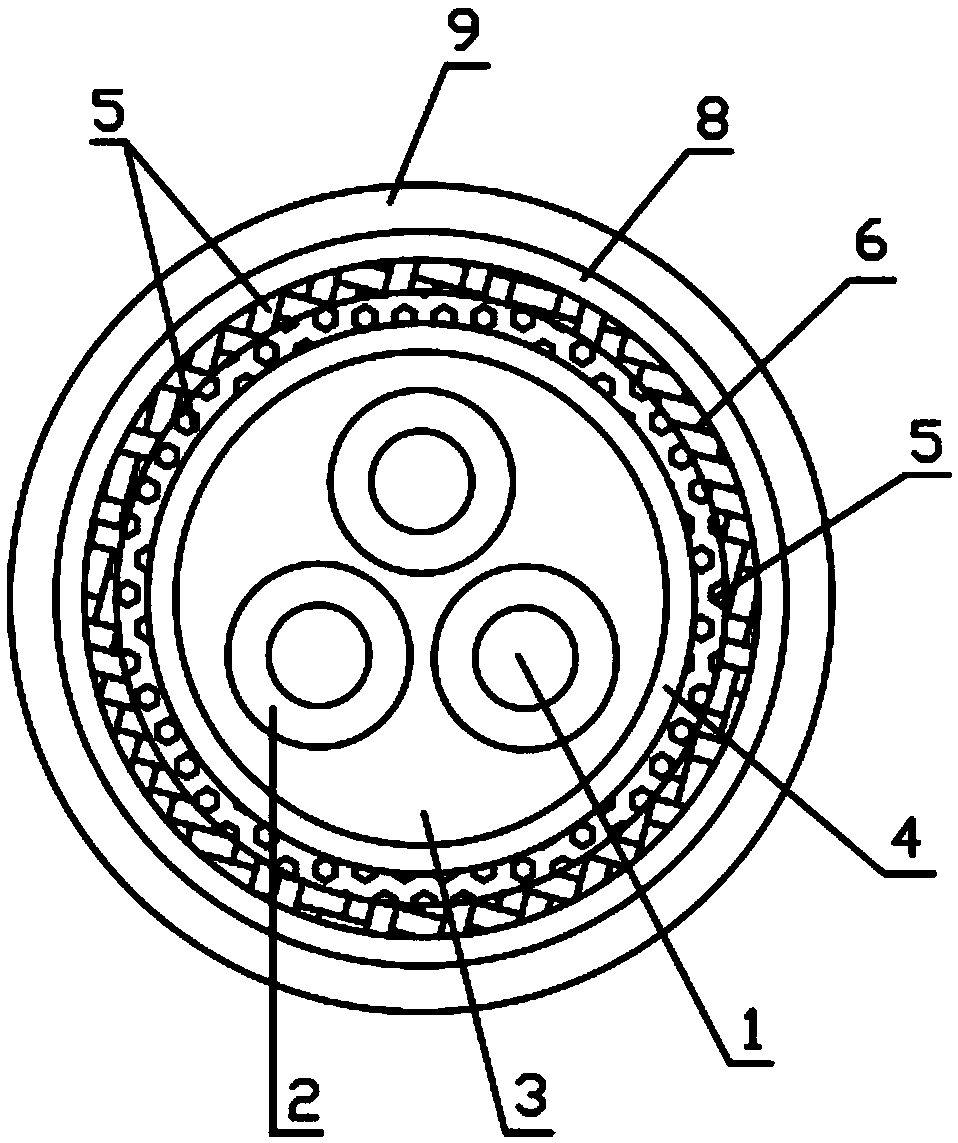

[0027] Such as figure 1 As shown, the halogen-free low-smoke flame-retardant cross-linked polyolefin insulated environmental protection cable of the present invention includes a three-phase cable core 1, an insulation layer 2 is provided outside the cable core 1, and a water blocking filling layer is sequentially provided outside the insulation layer 2 3. The tape 4 and inner sheath, and the water blocking filling layer 3 is filled with water blocking yarn. The inner sheath includes a first inner sheath 5, the first inner sheath 5 includes a first flame-retardant ring sleeve 51 and a first water-blocking ring sleeve 52, and the first flame-retardant ring sleeve 51 along the long axis of the cable And the first water blocking ring sleeve 52 alternately arranged and connected by glue

Embodiment 2

[0029] Further improved on the basis of Example 1, a halogen-free low-smoke flame-retardant cross-linked polyolefin insulated environmental protection cable, the inner sheath also includes a second inner sheath 6, the second inner sheath 6 is arranged in the first inner Outside the sheath 5, the second inner sheath 6 includes a second flame-retardant ring sleeve 61 and a second water blocking ring sleeve 62. The second flame-retardant ring sleeve 61 and the second water-blocking ring sleeve 62 are alternately arranged and connected along the long axis of the cable. The second flame-retardant ring sleeve 61 and the first flame-retardant ring sleeve 51 have the same axial length. The axial lengths of the water blocking ring sleeve 62 and the first water blocking ring sleeve 52 are equal; and in the radial direction of the cable, the second flame-retardant ring sleeve 61 is in contact and opposed to the first water blocking ring sleeve 52. The ring sleeve 62 is in contact and oppo...

Embodiment 3

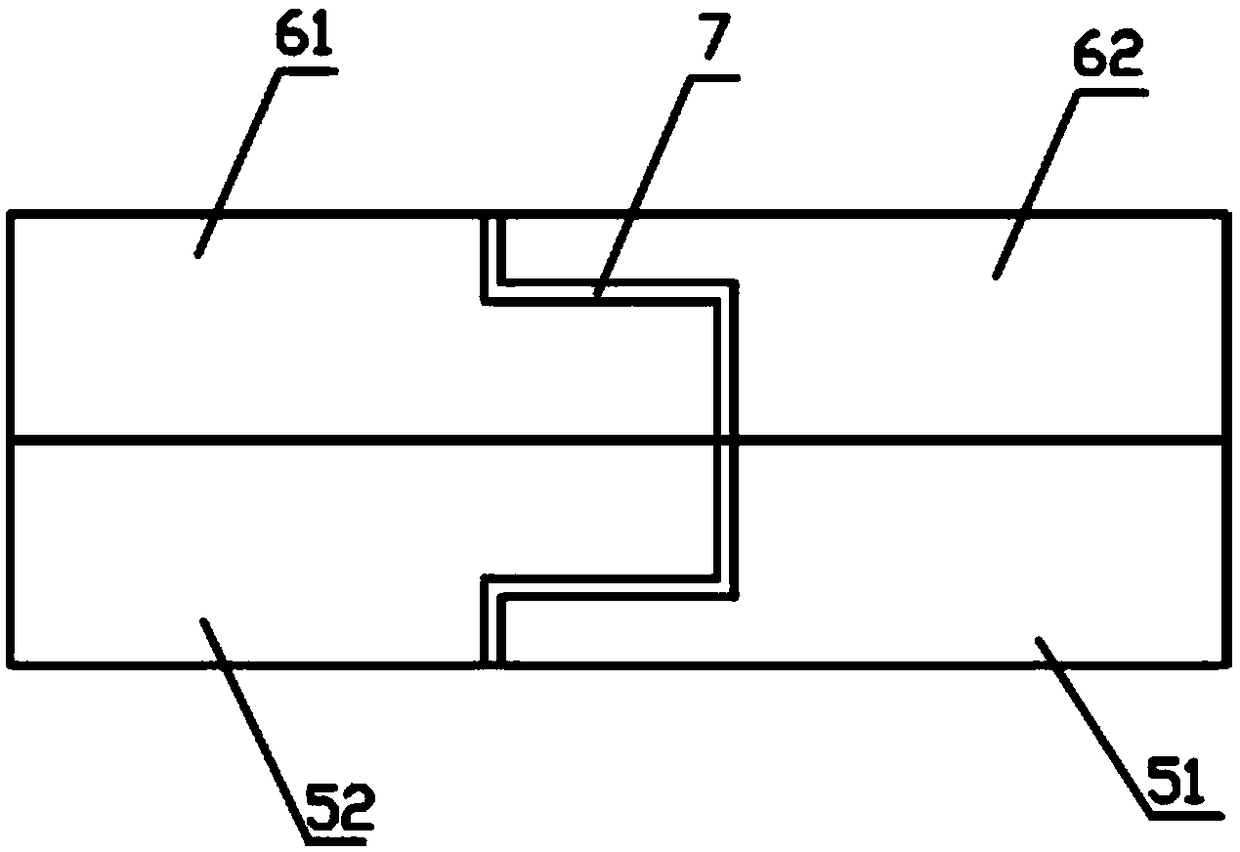

[0031] Such as figure 2 As shown, further improved on the basis of embodiment 2, a halogen-free low-smoke flame-retardant cross-linked polyolefin insulated environmental protection cable, the outer diameter of the interface end of the first flame-retardant ring sleeve 51 is smaller than that of the first flame-retardant ring sleeve 51 The outer diameter of the ring sleeve section, the inner diameter of the interface end of the first water blocking ring sleeve 52 is larger than the inner diameter of the main ring sleeve section of the first water blocking ring sleeve 52, and the interface end of the first water blocking ring sleeve 52 is sleeved on the first flame-retardant ring sleeve 51 is connected to the interface end; the outer diameter of the interface end of the second flame-retardant ring sleeve 61 is smaller than the outer diameter of the main ring sleeve section of the second flame-retardant ring sleeve 61, and the inner diameter of the interface end of the second wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com