Novel building material processing powder mixer

A new type of building material and mixer technology, applied in the direction of mixers, mixing methods, and solid-solid mixing, can solve the problems of powder accumulation at the bottom, fast powder outflow speed, unfavorable collection operation, etc., to reduce the outflow speed, The effect of improving production efficiency and slowing down the outflow speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

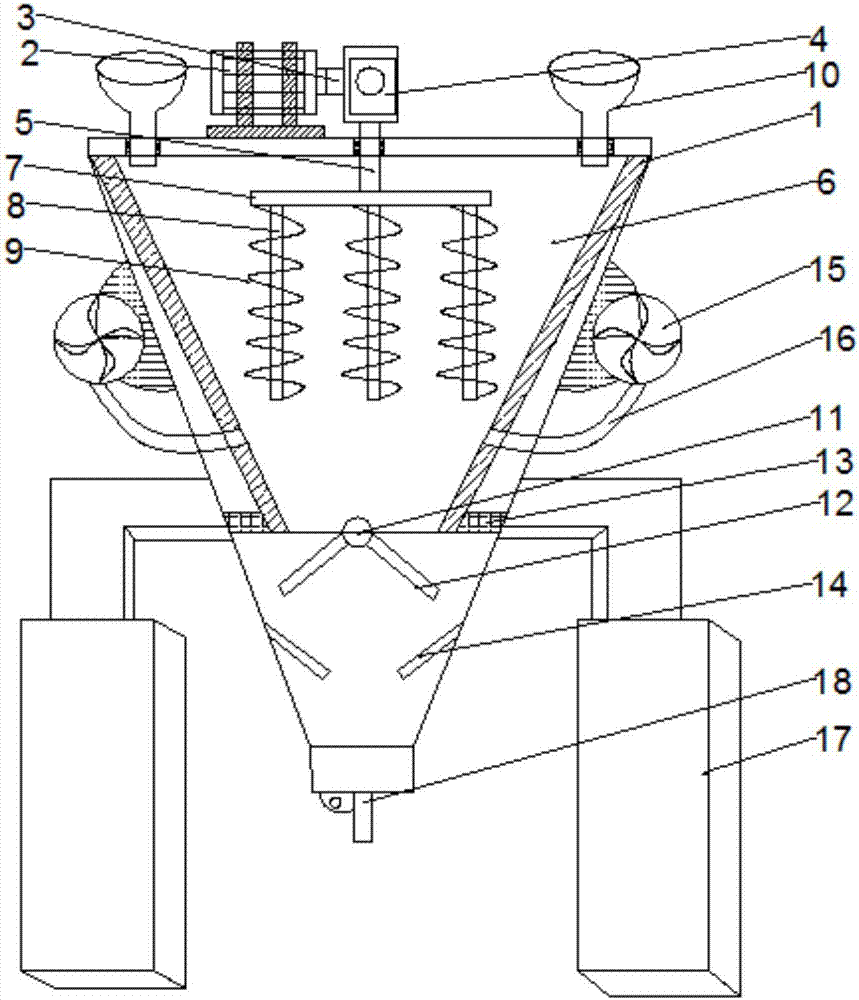

[0017] Such as figure 1 As shown, the present invention provides a new type of building material processing powder mixer, including a mixing body 1, the mixing body 1 is conical, which is conducive to more comprehensive mixing, and the top of the mixing body 1 is provided with a motor 2, so The electric motor 2 is connected with a differential 4 through a power rod 3, and the differential 4 is connected with the mixing inner cavity 6 of the mixing body 1 through a rotating shaft 5, which can drive the rotating shaft 5 to rotate, and the rotating shaft 5 passes through the rotating shaft 7 Three stirring rods 8 are connected, and a spiral plate 9 is arranged on a week of the three stirring rods 8, which can improve the efficiency of stirring. The top two ends of the mixing inner chamber 6 are provided with feeding funnels 10, and the mixing A hinge shaft 11 is arranged in the middle of the bottom of the inner chamber 6, and closing plates 12 are arranged on both sides of the hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com