A sequential solidification process device and method used in vacuum smelting equipment

A technology of vacuum melting and sequential solidification, applied in the field of casting equipment, can solve the problems of reducing the solid-liquid interface angle, reducing the total solidification time, and the expansion of the solid-liquid interface angle is not helpful, so as to increase the longitudinal solidification speed and reduce the solid-liquid interface angle. The effect of increasing the interface angle and ensuring the feeding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

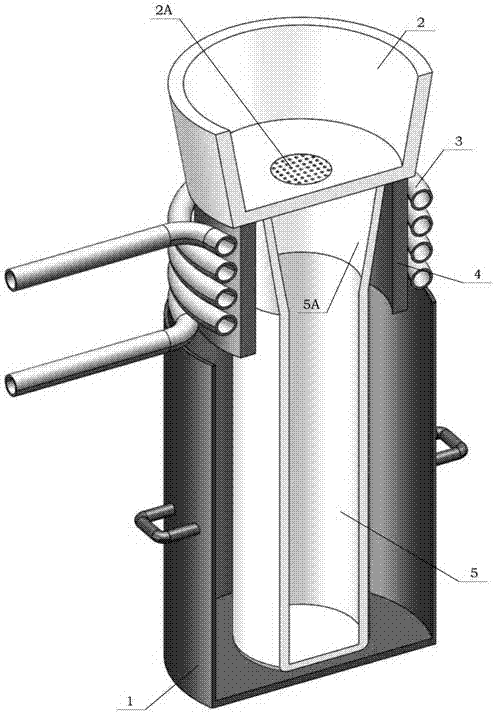

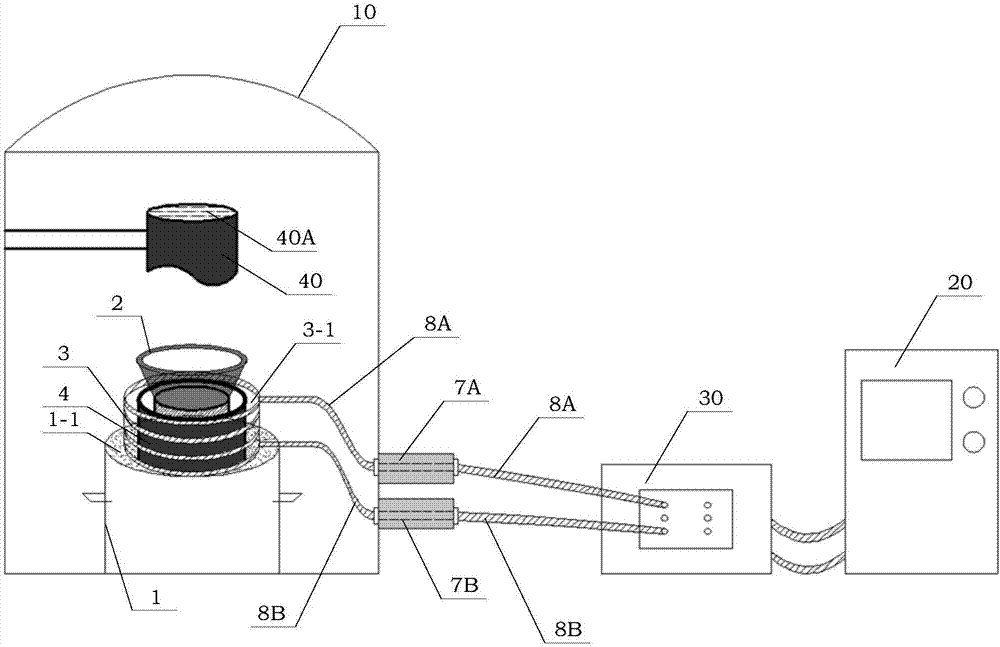

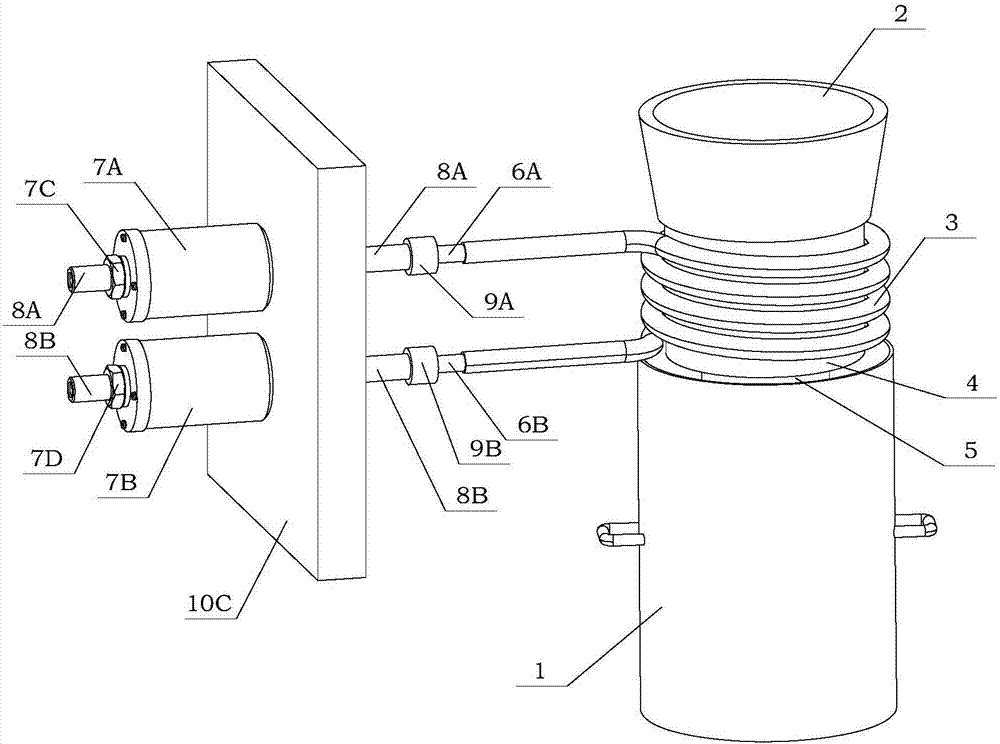

[0076] Such as figure 1 The improved vacuum smelting equipment of the present invention shown in the present invention adopts vacuum induction furnace to smelt nickel-based superalloy, and casts it in an yttrium oxide ingot mold. The specific method is as follows:

[0077] Step 1: Before closing the furnace cover and vacuuming, set the water-cooled copper plate as the cooling device and place it in the vacuum induction furnace. The upper surface area of the water-cooled copper plate is 40% of the cross-sectional area of the cast rod. Water inlet and outlet, and cooling water channels are set in the copper plate; the yttrium oxide ceramic ingot mold is preheated to 900°C and placed in the base. The segment inner diameter is 100 mm. Place the base and the ingot mold on the water-cooled copper plate, and make the center of the water-cooled copper plate coincide with the center of the ingot mold, and place the induction heating coil outside the riser. The inner diameter of the ...

Embodiment 2

[0083] Such as figure 1 The improved vacuum smelting equipment of the present invention shown in the present invention adopts vacuum induction furnace to smelt nickel-based superalloy, and casts it in a magnesium oxide ingot mould. The specific method is as follows:

[0084] Step 1: Before closing the furnace cover and vacuuming, set the water-cooled copper plate as the cooling device and place it in the vacuum induction furnace. Water inlet and outlet, and cooling water channels are set in the copper plate; the magnesium oxide ceramic ingot mold is preheated to 420°C and placed in the base. The maximum inner diameter of the riser section of the ingot mold is 110mm, the minimum inner diameter is 90mm, The segment inner diameter is 90mm. Place the base and the ingot mold on the water-cooled copper plate, and make the center of the water-cooled copper plate coincide with the center of the ingot mold, and place the induction heating coil outside the riser. The inner diameter of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com