Device, method and 3D printing system for preparing metal powder by ultrasonic vibration atomization

A metal powder, ultrasonic vibration technology, applied in the field of metal 3D printing, can solve the problems of difficult continuous powder milling, consumption of large inert gas, harsh powder shape and particle size, etc., to simplify equipment structure, reduce powder storage and transportation, and narrow particle size distribution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention is described in detail below in conjunction with accompanying drawing:

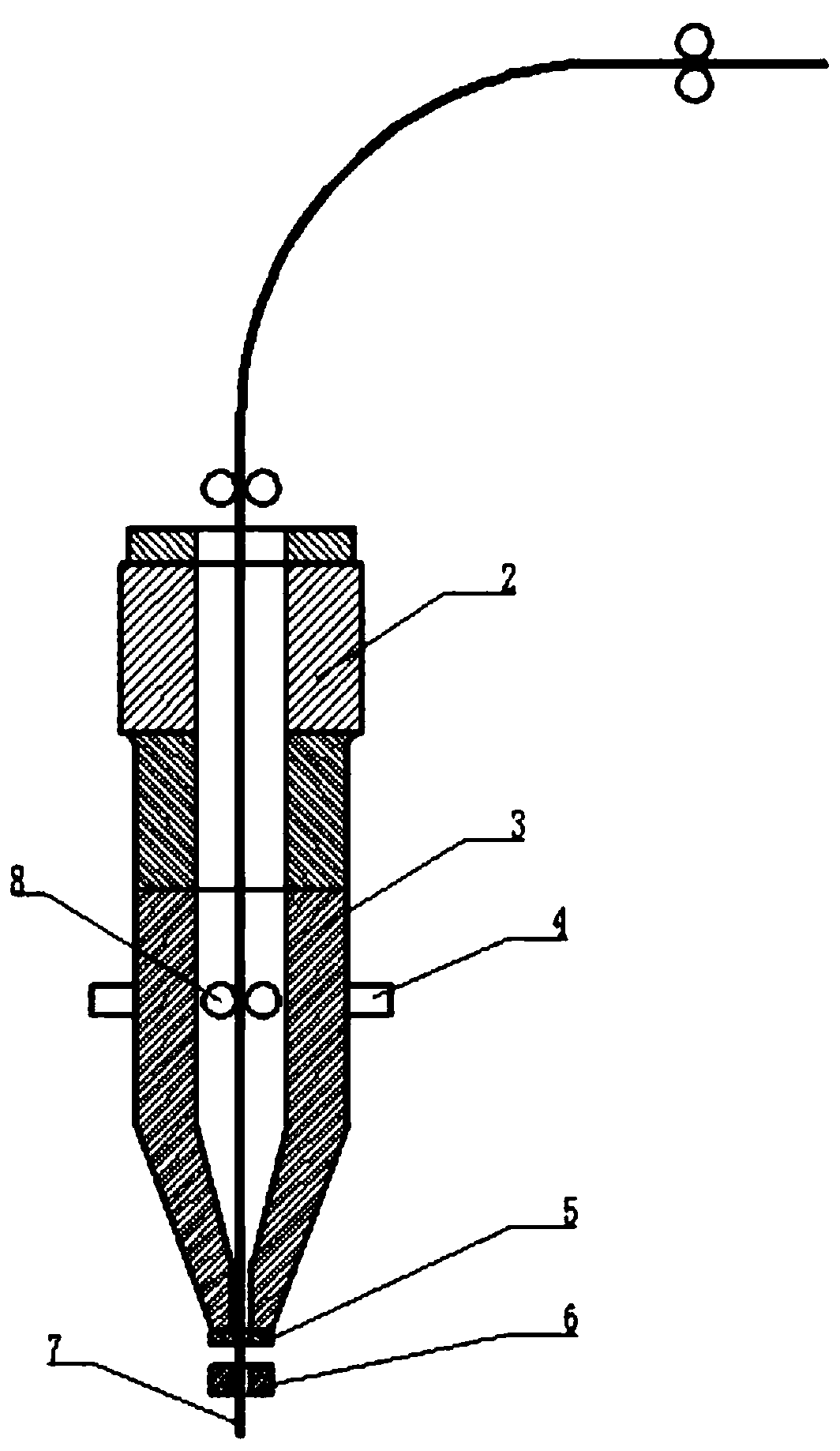

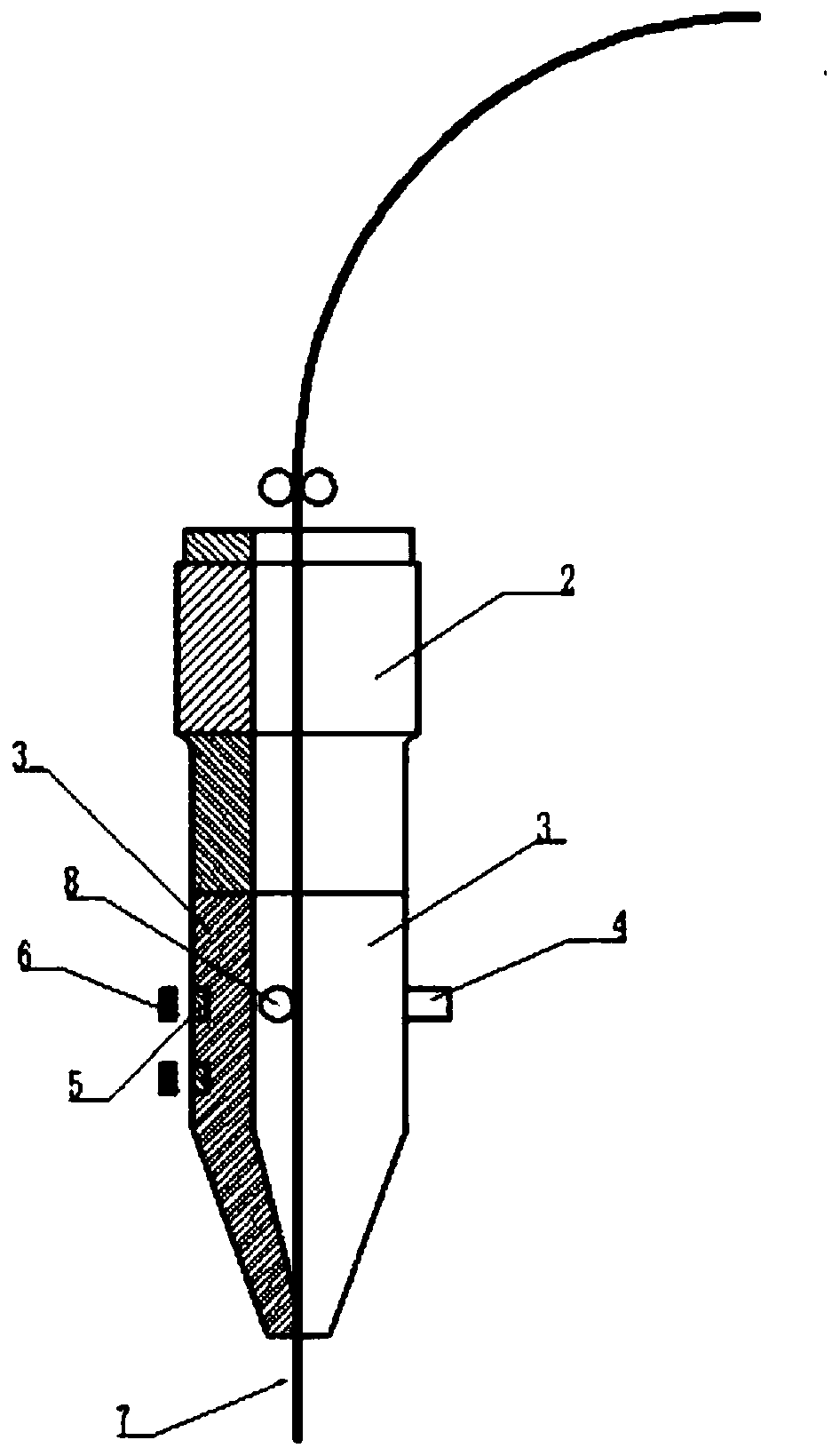

[0050] On the one hand, the present invention discloses a device for preparing metal powder by ultrasonic vibration atomization, including: an ultrasonic vibration system, an ultrasonic amplitude device, a metal wire 7, a locking system, a wire feeding system, and a heat source;

[0051] Among them, the ultrasonic vibration system includes an ultrasonic generator, a transducer 2, etc., to generate ultrasonic waves and convert energy; the ultrasonic horn device adopts a horn 3;

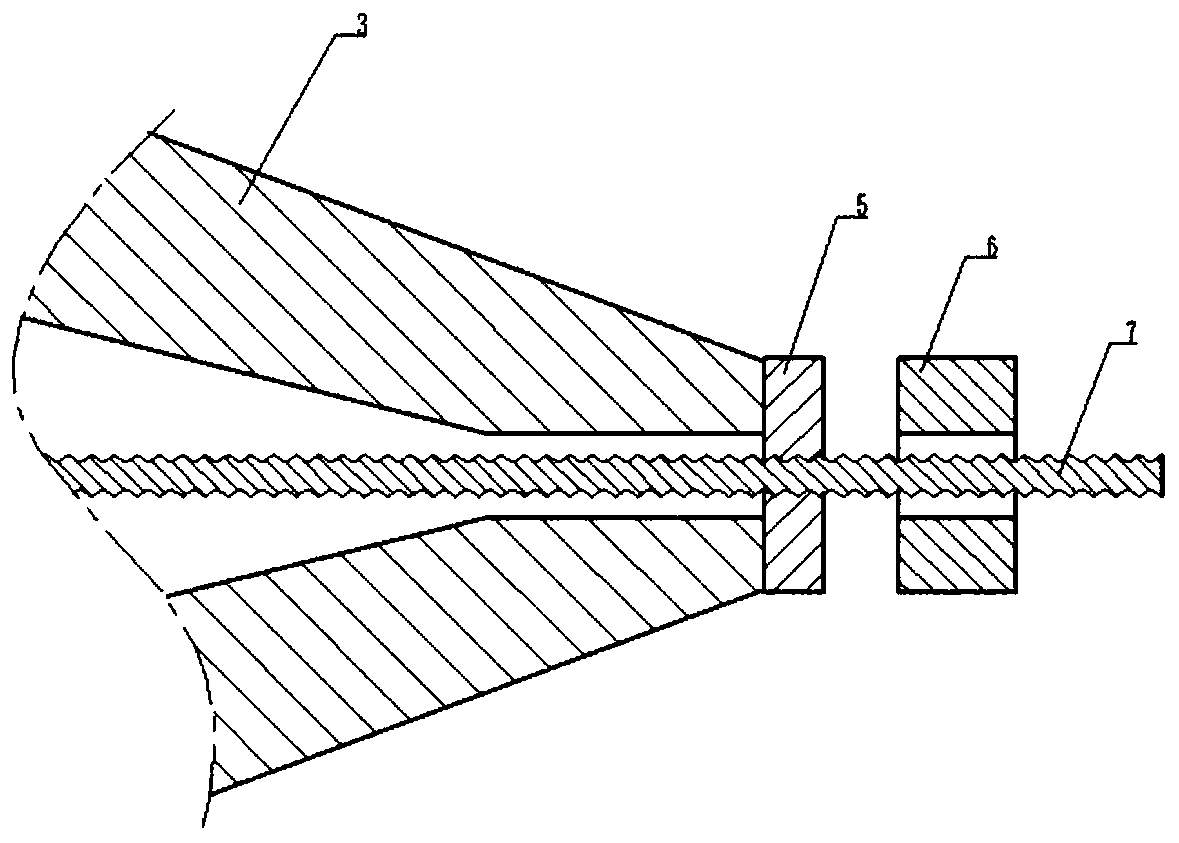

[0052]A locking device 5 is arranged on the horn 3 , and the locking device 5 becomes a part of the horn 3 . The force applicator 6 exerts an external force on the locking device 5 to change its inner diameter.

[0053] The front part of the wire 7 is locked by the locking device 5 , and the rear part is bent to change direction. In this way, a section of the wire 7 is locked as the load of the horn 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com