Prepreg band guide-in composite device and working method thereof

A composite device and working method technology, which is applied to other household appliances, tubular objects, household appliances, etc., can solve the problems of inability to make large pipe diameters, limited pipe diameters, and hollow pipe walls, etc., to achieve increased physical properties and increased friction , the effect of improving the composite strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

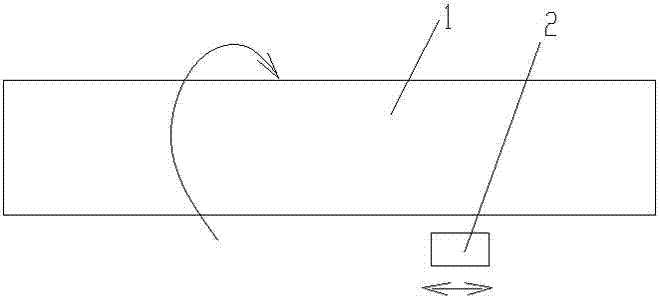

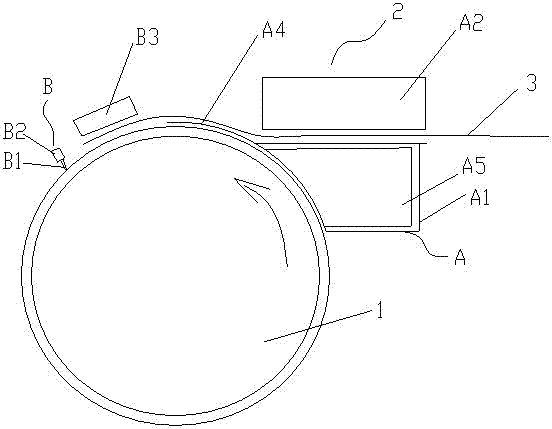

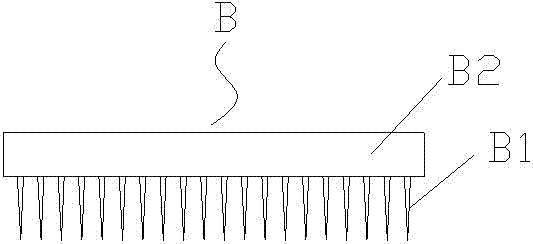

[0025] The composite device for introducing prepreg tape in the present invention includes a horizontally arranged and rotating mold core 1 and a frame 2 that reciprocates along the length direction of the mold core. Structure B, the plow-type iron structure A includes a stainless steel heat-conducting iron A1 close to the surface of the mold core and a heater A2 arranged above the stainless steel heat-conducting iron, and the stainless steel heat-conducting iron A1 and the heater A2 pass through There is a prepreg tape 3 that is continuously introduced and wound on the mold core. The stainless steel heat conduction iron A1 has an arc-shaped forward extension piece A4 that is attached to the surface of the mold core. The stainless steel heat conduction iron A1 is equipped with a second heating device A5; the needle comb type exhaust s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com