Photocatalytic self-cleaning type water permeable brick and preparation method thereof

A photocatalytic and self-cleaning technology, which is applied to clay products, other household utensils, pavements paved with prefabricated blocks, etc., can solve the problems of waste, large titanium dioxide, and no photocatalysis, so as to reduce waste, Effects of cost saving and good environmental coordination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

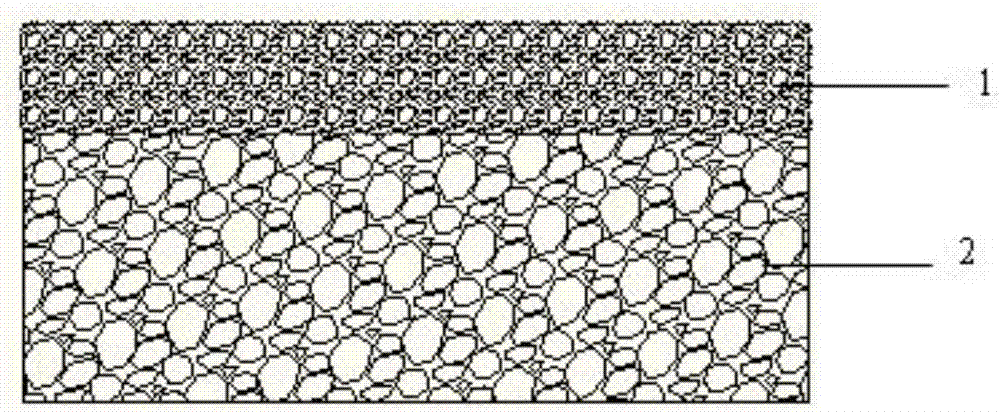

[0027] 1-2.5mm ceramic waste particles, natural vanadium-containing rutile powder, kaolin, potassium albite feldspar, and water glass solution with a mass concentration of 25%, and the ratio is 70:10:5:5:10 by weight and mixed evenly. Made into a photocatalytic surface layer compound.

[0028] 3-5mm ceramic waste particles, kaolin, potassium albite feldspar, and water glass solution with a mass concentration of 25% are mixed uniformly in a weight ratio of 80:5:5:10 to make a matrix layer mixture.

[0029] When the above-mentioned mixture is pressed into adobe, two times of distribution are used, and one time is pressed into shape, that is, the metal mold is first filled with a photocatalytic surface layer mixture of 8mm; Pressure 25MPa. The pressed bricks were dried at 150°C for 12 hours, then fired at 1100°C for 2 hours, and naturally cooled to obtain a natural mineral photocatalytic self-cleaning permeable brick with a pore gradient structure. The performance indicators of...

Embodiment 2

[0031] 1-2.5mm ceramic waste particles, natural vanadium-containing rutile powder, kaolin, potassium albite feldspar, water glass solution with a mass concentration of 25%, and the proportions are 70:12:4:4:10 by weight and mixed evenly. Made into a photocatalytic surface layer compound.

[0032] 3-5mm ceramic waste particles, kaolin, potassium albite feldspar, and water glass solution with a mass concentration of 25% are mixed uniformly in a weight ratio of 82:4:4:10 to make a matrix layer mixture.

[0033] When the above-mentioned mixture is pressed into adobe, two times of distribution are used, and one time is pressed to form, that is, the metal mold is first filled with a photocatalytic surface layer mixture of 5 mm; Pressure 20MPa. The pressed bricks were dried at 110°C for 8 hours, then fired at 900°C for 1 hour, and cooled naturally to obtain a natural mineral photocatalytic self-cleaning permeable brick with a pore gradient structure. The performance indicators of p...

Embodiment 3

[0035] 1-2.5mm refractory waste particles, natural vanadium-containing rutile powder, kaolin, potassium albite feldspar, and water glass solution with a mass concentration of 25%, the ratio is 70:10:5:5:10 by weight and mixed evenly , made of photocatalytic surface layer mixture.

[0036] 3-5mm refractory waste particles, kaolin, potassium albite feldspar, and water glass solution with a mass concentration of 25% are mixed uniformly in a weight ratio of 80:5:5:10 to make a matrix layer mixture.

[0037] When the above-mentioned mixture is pressed into brick adobe, two times of distribution are used, and one time is pressed to form, that is, the photocatalytic surface layer mixture is first filled in the metal mold 6mm; then the base layer mixture is filled on it, and then pressed and formed once Pressure 23MPa. After drying the pressed bricks at 120°C for 10 hours, they were fired at 1000°C for 1.5 hours, and naturally cooled to obtain a natural mineral photocatalytic self-cl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com