High-gloss glass fiber reinforced modified nylon

A modified nylon and high-gloss technology, applied in the field of composite materials, can solve the problems of reducing fluidity and fatigue resistance of final products, affecting material mechanical properties, increasing production costs, etc., to achieve increased absorption and dissipation effects, high Glossy, not easy to tear off effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

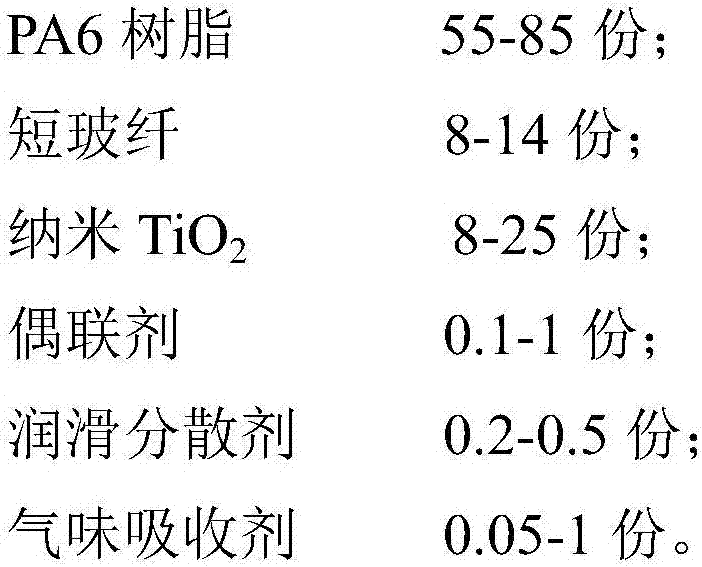

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions in the embodiments of the present invention will be described clearly and completely below. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art without creative work shall fall within the protection scope of the present invention.

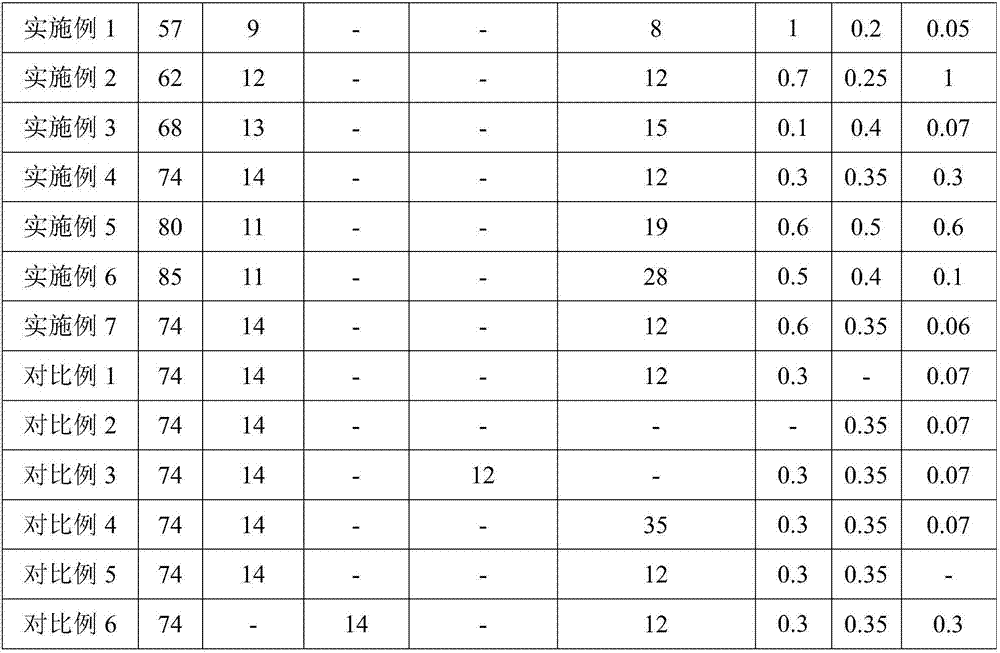

[0023] Weigh the raw materials according to the formula of each embodiment in Table 1 below, add the weighed sample into the high-mixer, rotate at 800 rpm, and mix for 20 minutes. After fully mixing, the premix is obtained. The mixture is transferred to the twin-screw extruder, the extrusion temperature of the twin-screw extruder is 190℃, the extrusion speed of the twin-screw extruder is 600 rpm, extrusion granulation, and high-gloss glass fiber reinforced Modified nylon.

[0024] Table 1 Parts by weight of high-gloss glass ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com