Environmental-friendly and waterproof urea-formaldehyde resin adhesive and preparation method thereof

A urea-formaldehyde resin and adhesive technology, which is applied in the field of sheet metal processing, can solve the problems of poor water resistance and single effect, and achieve the effects of avoiding chemical pollution, excellent waterproof effect and simple process operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

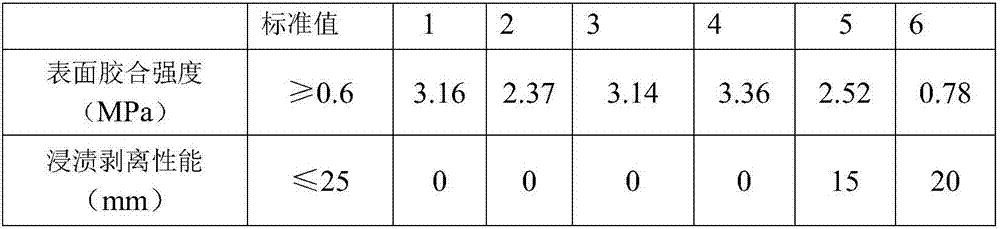

Examples

Embodiment 1

[0021] Environmental protection, waterproof urea-formaldehyde resin adhesive, including the following raw materials: high-gluten flour, sulfuric acid, urea-formaldehyde resin glue, pigment, coagulant.

[0022] Raw materials: 15 parts of high-gluten flour, 1 part of 75% sulfuric acid, 35 parts of urea-formaldehyde resin glue, 2 parts of pigment, 1 part of coagulant, set aside;

[0023] S1: Preparation of environmentally friendly and waterproof base glue

[0024] S1-1: Take high-gluten flour, mix it with water at a ratio of 1:10, stir, place in a constant temperature water bath at a temperature of 53°C, stir in one direction, slowly add sulfuric acid diluted to 56% at a rate of 0.05ml / 10s , after 3 minutes and 20 seconds, the dropwise addition is completed, and the mixture is fully mixed to obtain the floc;

[0025] S1-2: Take urea-formaldehyde resin glue, add the floc prepared in step S1-1, stir for 2 minutes, let stand for 4 minutes, and set aside;

[0026] S2: gelling

[0...

Embodiment 2

[0029] Environmental protection, waterproof urea-formaldehyde resin adhesive, including the following raw materials: high-gluten flour, sulfuric acid, urea-formaldehyde resin glue, pigment, coagulant.

[0030] Raw materials: 35 parts of high-gluten flour, 2 parts of 75% sulfuric acid, 40 parts of urea-formaldehyde resin glue, 3 parts of pigment, 2 parts of coagulant, set aside;

[0031] S1: Preparation of environmentally friendly and waterproof base glue

[0032] S1-1: Take high-gluten flour, mix it with water at a ratio of 1:10, stir, place in a constant temperature water bath at a temperature of 55°C, stir in one direction, slowly add sulfuric acid diluted to 53% at a rate of 0.08ml / 10s, After 4 minutes and 10 seconds, the dropwise addition is completed, and the mixture is fully mixed to obtain the floc;

[0033] S1-2: Take urea-formaldehyde resin glue, add the floc prepared in step S1-1, stir for 2 minutes, let stand for 5 minutes, and set aside;

[0034] S2: gelling

[...

Embodiment 3

[0037] Environmental protection, waterproof urea-formaldehyde resin adhesive, including the following raw materials: high-gluten flour, sulfuric acid, urea-formaldehyde resin glue, pigment, coagulant.

[0038] Take 20 parts of high-gluten flour, 1.5 parts of 75% sulfuric acid, 30 parts of urea-formaldehyde resin glue, 2.5 parts of pigment, and 1 part of coagulant accelerator as raw materials, and set aside;

[0039] S1: Preparation of environmentally friendly and waterproof base glue

[0040] S1-1: Take high-gluten flour, mix it with water at a ratio of 1:10, stir, place in a constant temperature water bath with a temperature range of 60°C, stir in one direction, and slowly add sulfuric acid diluted to 53% at a rate of 0.1ml / 11s , 2min45s dropwise is completed, fully mixed to obtain the floc;

[0041] S1-2: Take urea-formaldehyde resin glue, add the floc prepared in step S1-1, stir for 1 min, let stand for 3 min, and set aside;

[0042] S2: gelling

[0043] Lower the temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com