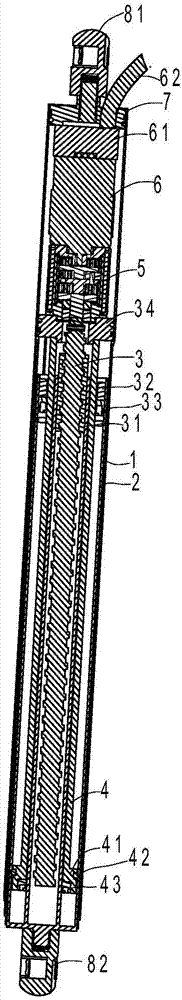

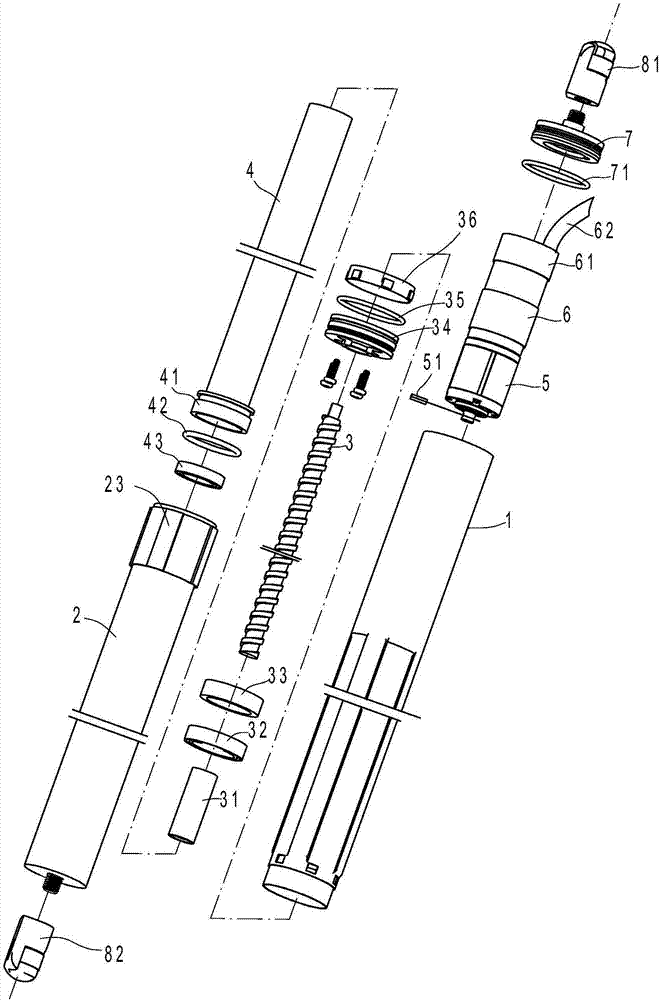

Smart motor driving air cylinder device

A technology for driving cylinders and cylinder devices, used in power control mechanisms, door/window fittings, buildings, etc., can solve the problems of poor stability, increased bearing capacity, and high noise of steel springs, prevent cylinder liner from rotating, reduce the overall Length, effect of reducing motor wattage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0050] Embodiment 2, the piston 41 in this embodiment is provided with a through hole 411, and the through hole 411 communicates the air chambers at the front and rear ends of the piston 41, so that when the piston rod 4 is in motion and a large pressure difference is generated, the compressed gas can flow through the through hole. The flow in the hole ensures balance, so that the piston 41 is kept basically stable under the force of the compressed gas, thereby achieving better performance than the steel spring. Refer to Example 1 for other structures.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com