High-reliability and large power adjusting ratio diesel combustor

A reliable and high-power technology, which is applied in the heating burner and cooking fields, can solve the problem that the burner cannot meet high reliability and high power adjustment ratio at the same time, and achieve enhanced atomization effect, sufficient combustion, and good flame rigidity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

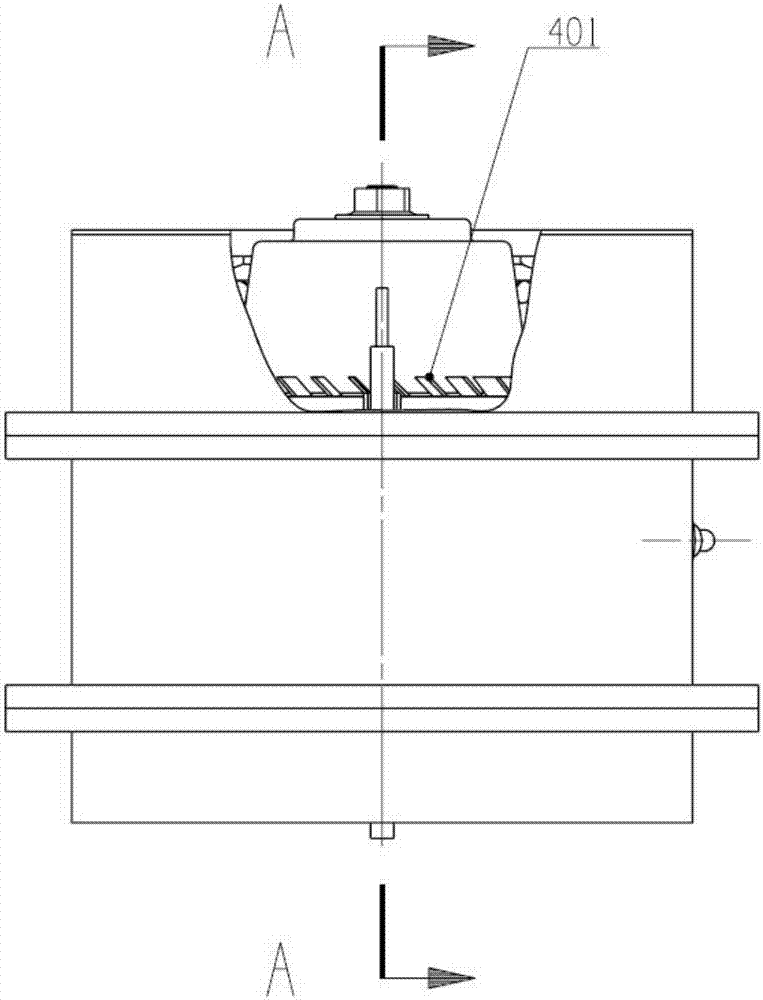

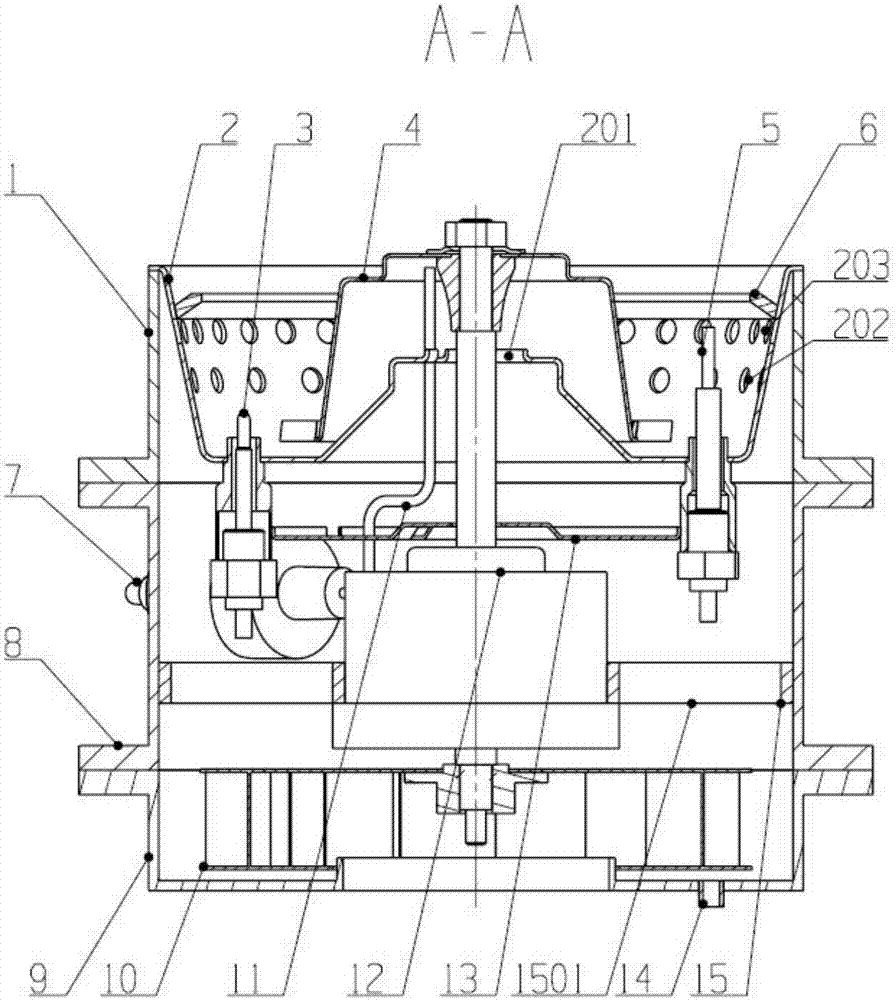

[0023] refer to figure 1 , figure 2 and image 3 , a diesel burner with high reliability and high power adjustment ratio, including outer wall 1, flame cup 2, beam flame ring 6, shell 8, base 9, rotor 4, oil pump 7, oil pipe 11, motor 12, motor support Frame 15, wind wheel 10, heat shield 13, igniter 3, fire detection sensor 5, oil drain pipe 14. The flame cup 2 opens upwards, the rotor 4 opens downwards, the rotor 4 is located in the flame cup 2, and the annular area between the flame cup 2 and the rotor 4 forms a combustion chamber; the motor 12 is arranged on the flame cup 2 through the motor support frame 15 Below, the rotor cup 4 and the wind wheel 10 are installed on the same output shaft of the motor 12, the rotor cup 4 is installed on the upper end of the output shaft of the motor 12, the wind wheel 10 is installed on the lower end of the output shaft of the motor 12, and the rotor 4 is used For atomized diesel oil, the wind wheel 10 is used to supply air for combu...

Embodiment 2

[0031] The structure of the present invention and its working process are the same as in Embodiment 1. In this example, two rings of air holes are arranged on the circumferential wall surface of the flame cup 2 from bottom to top, the lower ring of air holes 202, the air holes are evenly arranged in the circumferential direction, and the upper ring of air holes 203, the air holes are uniform Arrangement, the number of pores 203 in the upper circle is 1.5 to 2 times that of the pores 202 in the lower circle, and the diameter of each pore is 6 mm.

[0032] The flame beam ring 6 is arranged on the upper edge of the upper circle of air holes 203 or the upper edge of the lower circle of air holes 202 on the circumferential wall of the flame cup 2 .

Embodiment 3

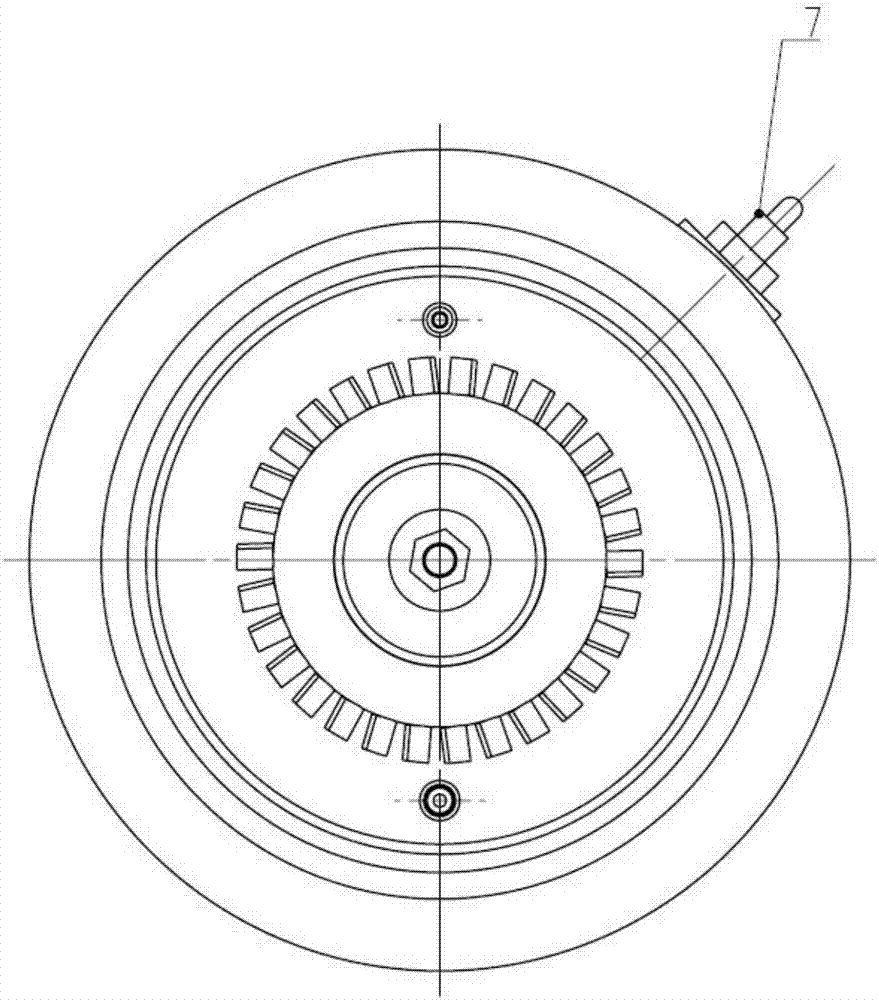

[0034] The structure and working process of the present invention are the same as in Embodiment 1. In this example, fins 401 are arranged on the lower edge of the tumbler, and the number of fins 401 is 30, which are evenly arranged in the circumferential direction. The fins 401 form a certain angle with the bottom plane of the flame cup 2. It is used to turbulence to strengthen the blending of diesel and air, and at the same time enhance the atomization effect of liquid diesel to form a liquid mist fan, which is conducive to ignition and complete combustion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com