A pyrolysis furnace for electronic waste

A technology of electronic waste and pyrolysis furnace, which is applied in the field of pyrolysis furnace and electronic waste pyrolysis furnace, which can solve the problems of unsealed pyrolysis furnace, low working efficiency of kiln and long pyrolysis cycle, etc., and achieves The effect of ensuring the atmosphere in the furnace, improving the production capacity of the device, and reasonable temperature distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

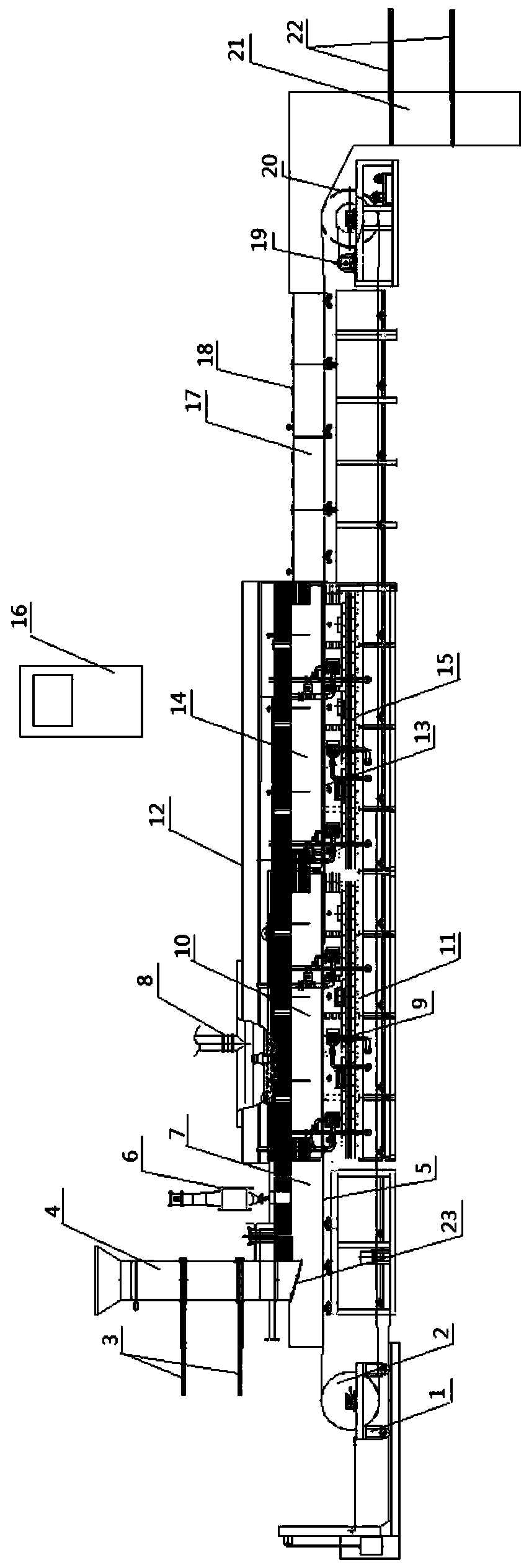

[0035] The structure of the electronic waste pyrolysis furnace of the present invention is as follows: figure 1 As shown: the main body of the electronic waste pyrolysis furnace includes a pyrolysis furnace body 12 , a combustion system, a transmission system and an electrical control system 16 . The furnace body of the pyrolysis furnace is a horizontal type, the furnace head of the pyrolysis furnace body is provided with a feed inlet 4, and the furnace tail is provided with a discharge port 21, and the area between the furnace head and the furnace tail is divided into preheating furnaces successively. Section 7, pyrolysis section 10, heat preservation section 14 and cooling section 17. The feed port of the burner is provided with a double-layer feed slide valve 3 and a feed platform, and the feed port is also provided with a distribution device 23 (such as a perforated plate). The preheating section area of the pyrolysis furnace body is provided with a pyrolysis gas outlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com