Hardware in-loop testing platform of electric vehicle whole-body layered control system and testing method thereof

A layered control system and electric vehicle technology, applied in the general control system, control/regulation system, test/monitoring control system, etc., can solve the problems of high voltage danger, high cost, narrow application range, etc., and achieve low cost , Occupy less resources, and the effect of convenient experimentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

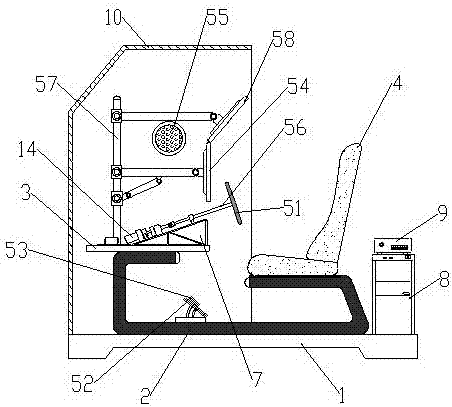

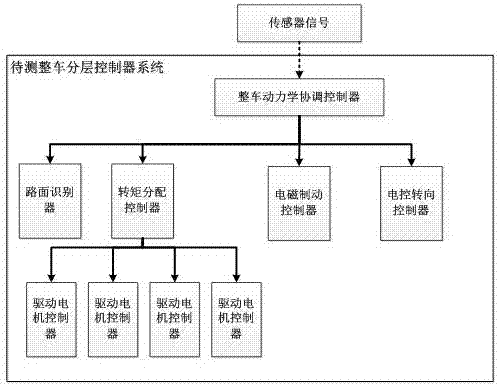

[0037]Example: see Figure 1 to Figure 4 , a hardware-in-the-loop test platform for electric vehicle controllers, including a bench base, a driving environment simulation system, a road sense feedback system, a host computer 8 (computer host), a target computer 9 (MicroAutoBox), a data acquisition card, and a whole to-be-tested Vehicle hierarchical control system.

[0038] Described stand matrix comprises base 1, is provided with a base frame 2 on base 1, is provided with a supporting platform 3 at the front end of base frame 2, is provided with seat 4 at the rear end of base frame 2; During specific implementation, seat Chair 4 is connected with underframe 2 by seat adjustment guide rail, can adjust driver's sitting posture by adjusting seat adjustment guide rail. An outer cover 10 is also provided at the front of the base 1, thereby reducing the influence of the outside world on the test process.

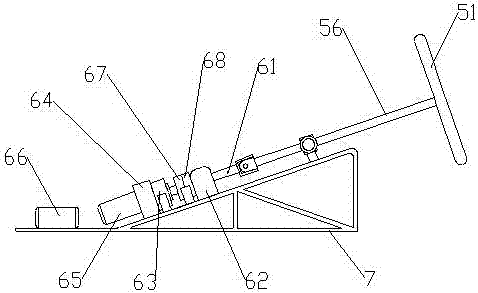

[0039] The driving environment simulation system includes a steering wheel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com