High-precision titration system for large-dose quantification of liquid

A quantitative liquid, high-dose technology, applied in the direction of control/regulation system, non-electric variable control, and simultaneous control of multiple variables, etc., can solve the problem of poor real-time acquisition of feedback, inability to eliminate or compensate, and inability to seek the best supplementary amount, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

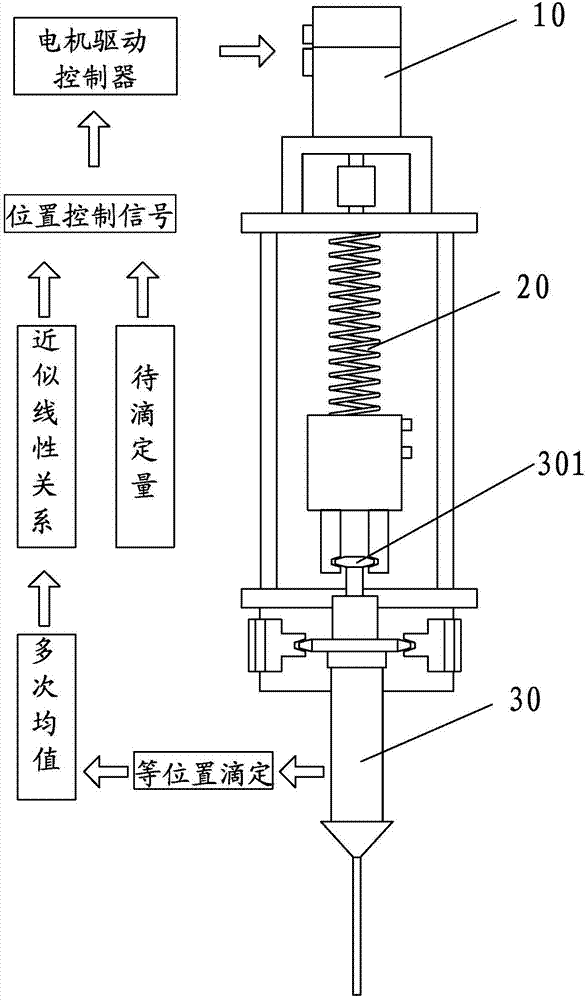

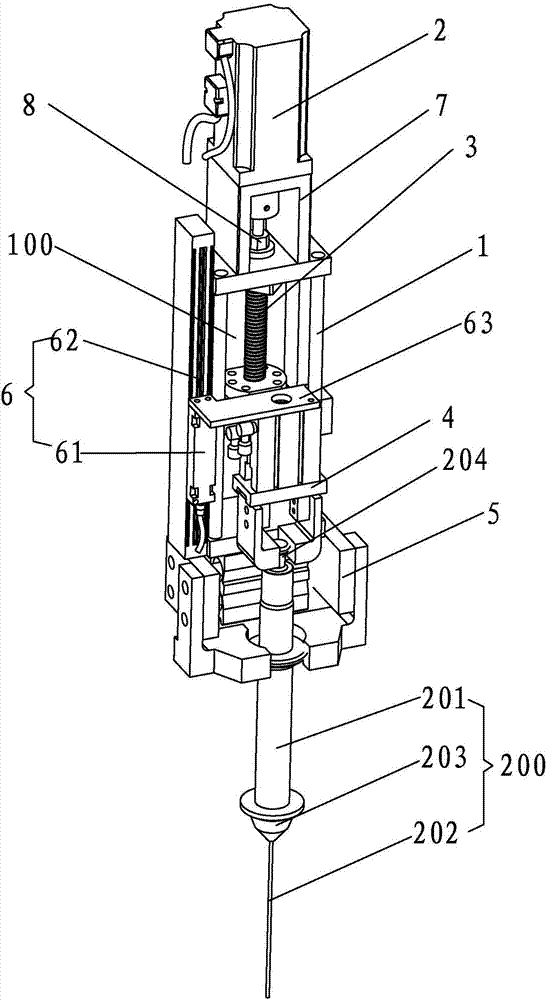

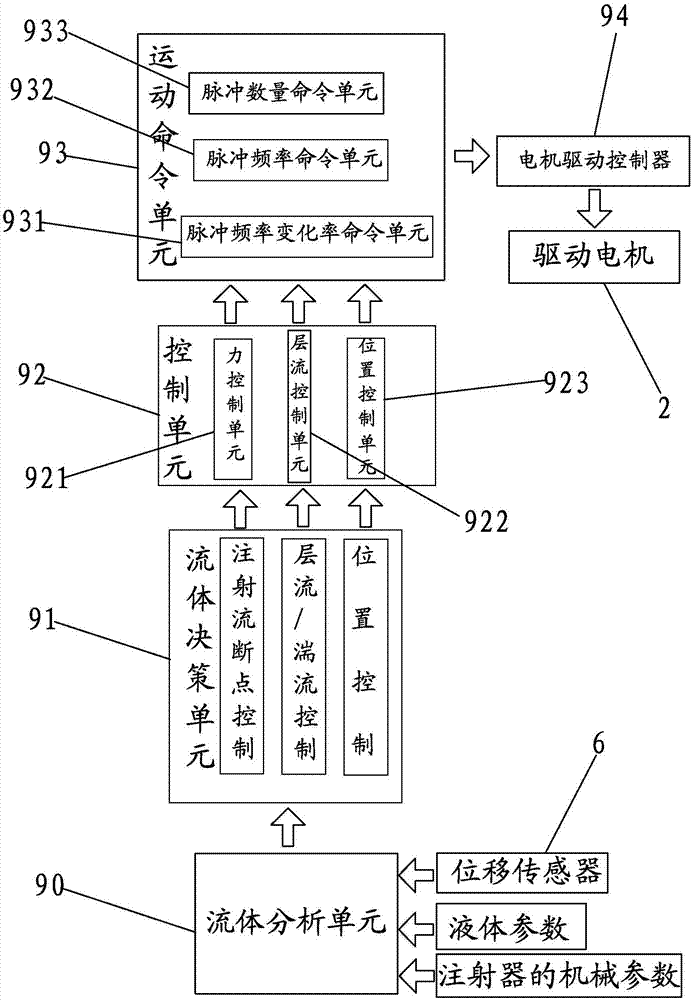

[0049] The high-precision titration system of the large-dose quantitative liquid of the present invention, such as figure 2 As shown, including the mechanical drive unit and the control system unit, where:

[0050] The mechanical drive unit includes titration system bracket 1, drive motor 2, transmission ball screw 3, syringe push handle holder 4, syringe holder 5 and displacement sensor 6, drive motor 2, transmission ball screw 3, syringe push handle The holder 4 and the syringe holder 5 are arranged sequentially from top to bottom. The top surface of the titration system support 1 is fixed with a drive motor support 7, and the drive motor 2 is erected and fixedly installed on the drive motor support 7, and the drive motor The support 7 is a hollow frame body, the output shaft of the drive motor 2 is set downwards, and extends into the hollo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com