Ultrathin asphalt mixture, and preparation method and application thereof

An asphalt mixture, an ultra-thin technology, is used in roads, on-site coagulating pavements, roads, etc., which can solve the problems of difficulty in reaching the fatigue performance, energy waste, and high cost, and achieve good anti-scattering performance, low cost, and high cost. Use performance-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

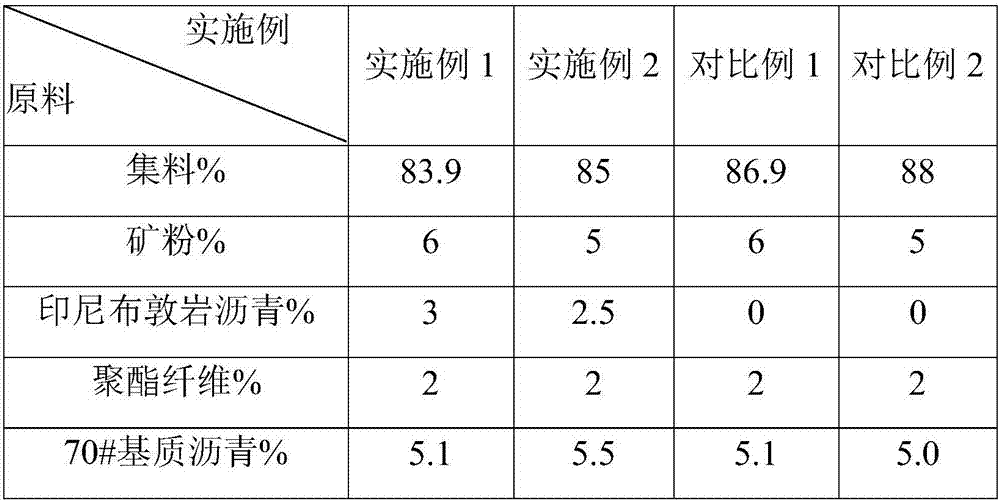

[0044] The raw material components of this example are as described in Table 2, and the following percentages are the mass percentages of each component relative to the total amount of raw materials.

[0045] Table 2

[0046]

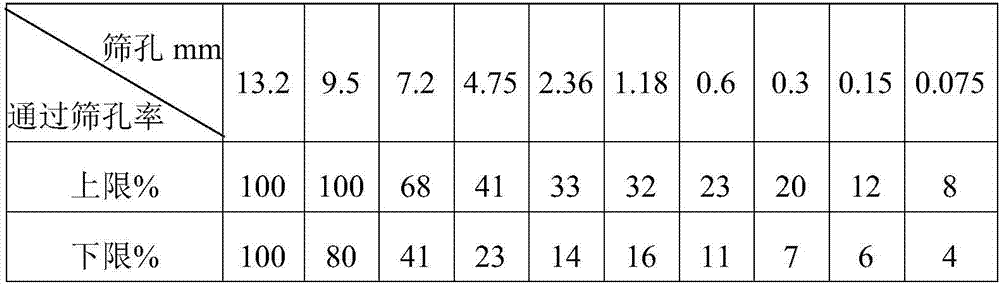

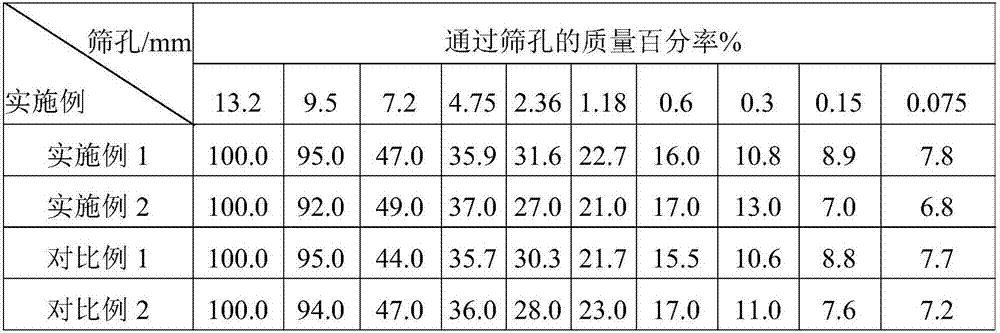

[0047] The gradation type of the ultra-thin asphalt mixture in this example is improved ECA-10, and the specific gradation composition is shown in Table 3.

[0048] table 3

[0049]

[0050] The preparation method of the ultra-thin asphalt mixture of the present embodiment comprises the following steps:

[0051] (1) Add aggregates at 180°C, polyester fiber and Indonesian Buton rock asphalt into the mixing pot, and mix at 180°C for 45 seconds to obtain mixture A;

[0052] (2) Mix mixture A and 70# base asphalt at 150°C for 15 seconds at 180°C to obtain mixture B;

[0053] (3) Mix mixture B with mineral powder for 5 seconds to obtain ultra-thin asphalt mixture.

Embodiment 2

[0055] The raw material components of this embodiment are as described in Table 2.

[0056] The gradation type of the ultra-thin asphalt mixture in this example is improved ECA-10, and the specific gradation composition is shown in Table 3.

[0057] The preparation method of the ultra-thin asphalt mixture of the present embodiment comprises the following steps:

[0058] (1) Add aggregates at 190°C, polyester fiber and Indonesian Buton rock asphalt into the mixing pot, and mix at 175°C for 50 seconds to obtain mixture A;

[0059] (2) Mix mixture A and 70# base asphalt at 160°C for 13 seconds at 175°C to obtain mixture B;

[0060] (3) Mix mixture B with mineral powder for 8 seconds to obtain ultra-thin asphalt mixture.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com