Health detecting system for composite board structure and work method thereof

A technology for health detection and composite board, which is applied in measurement devices, analysis of solids using sonic/ultrasonic/infrasonic waves, and material analysis using sonic/ultrasonic/infrasonic waves. , damage location, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

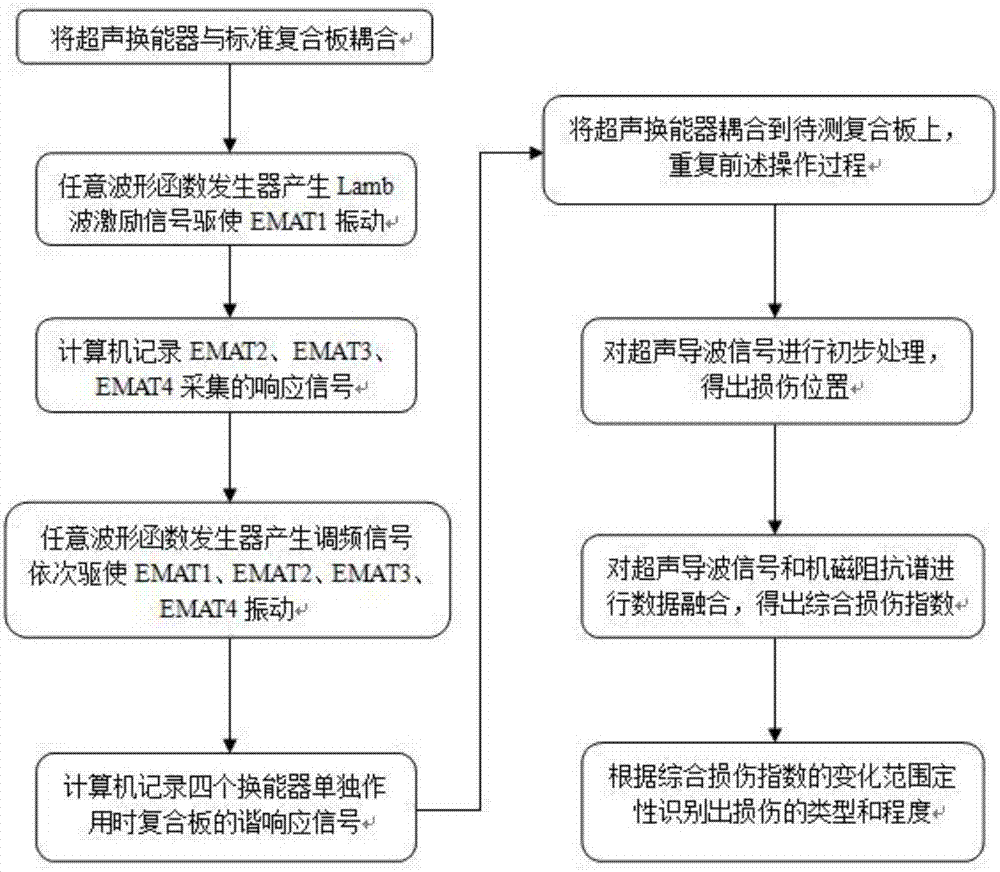

[0060] The present invention will be further described below with reference to the accompanying drawings.

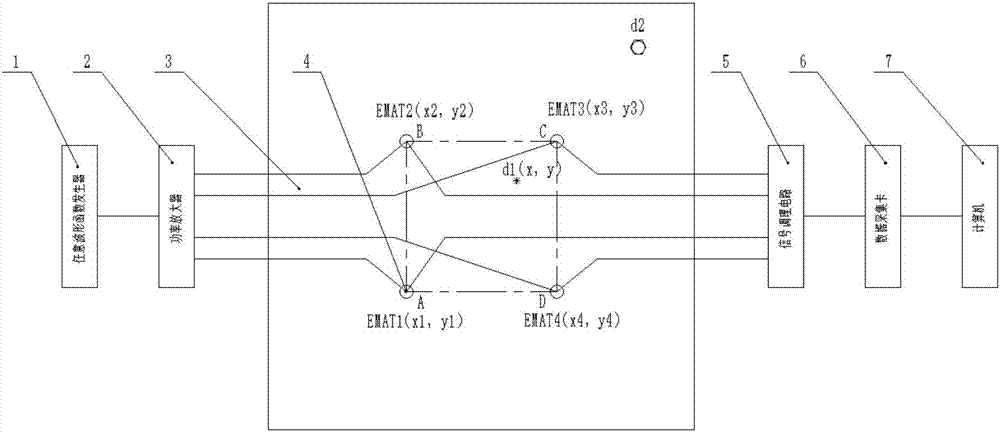

[0061] like figure 1 As shown, in the detection method of the present invention, an arbitrary waveform function generator 1, a power amplifier 2, four ultrasonic transducers 4 based on the magnetostrictive effect, a signal conditioning circuit 5, a data acquisition card 6 and a computer 7. In addition, there are two composite boards 3 used for inspection with the same material and size, one board is used as a reference standard without any damage and no defects such as loose screws, while the other board has a defect d1 and a loose screw d2.

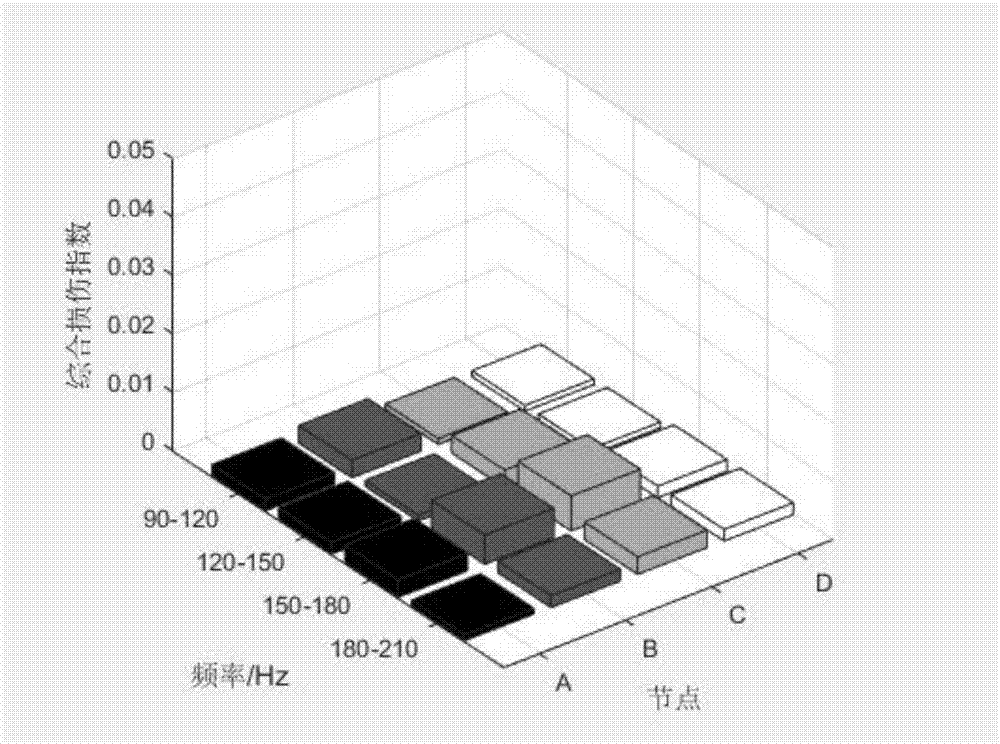

[0062] The size of the composite board 3 is 600mm×600mm×2mm. The excitation signal of the ultrasonic guided wave method is a sinusoidal signal of 5 to 20 cycles modulated by the Hanning window, and its center frequency is 100 to 300 kHz. The excitation signal of the machine magneto-impedance method is a sinusoidal frequency mod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com