Lithium battery containing current collector and preparation method thereof

A current collector, lithium battery technology, applied in battery electrodes, secondary batteries, electrode carriers/current collectors, etc., can solve the problems of reducing the service life of lithium ion batteries, copper/aluminum coating peeling, electrolyte corrosion, etc. The effect of copper/aluminum coating peeling, reducing peeling, and high compaction density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

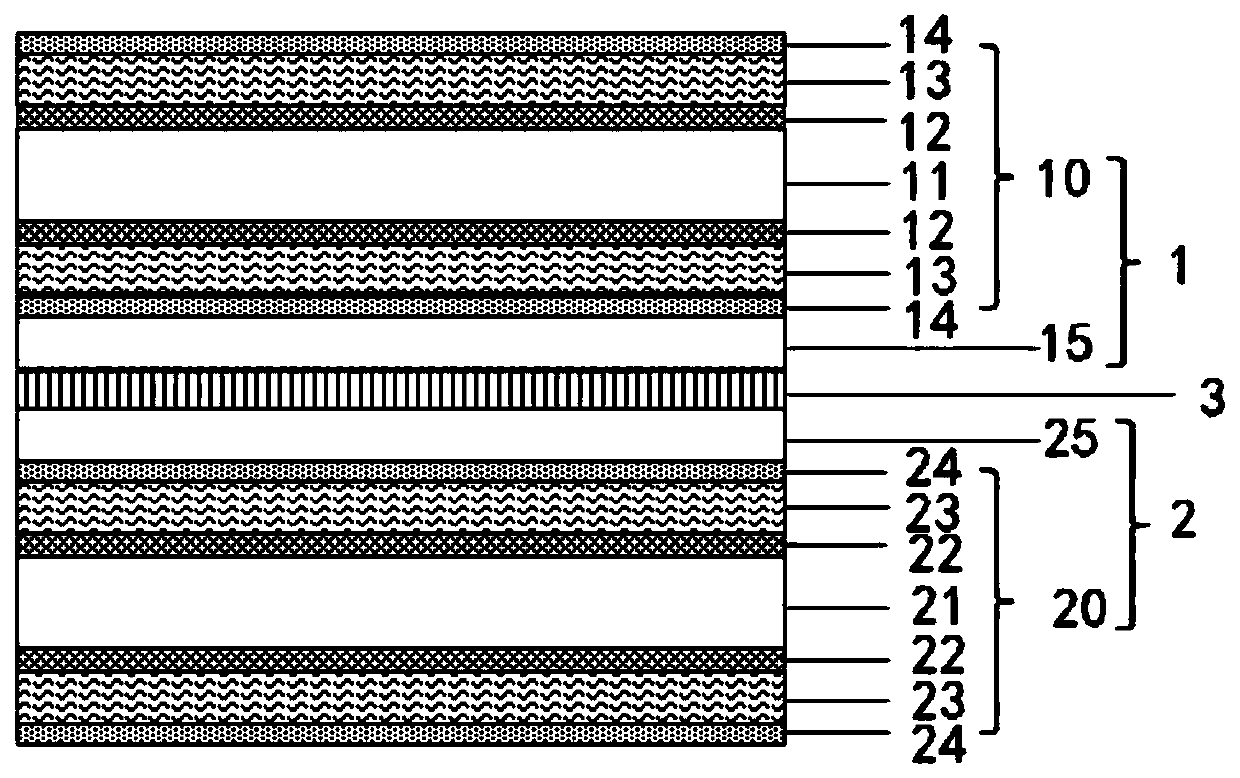

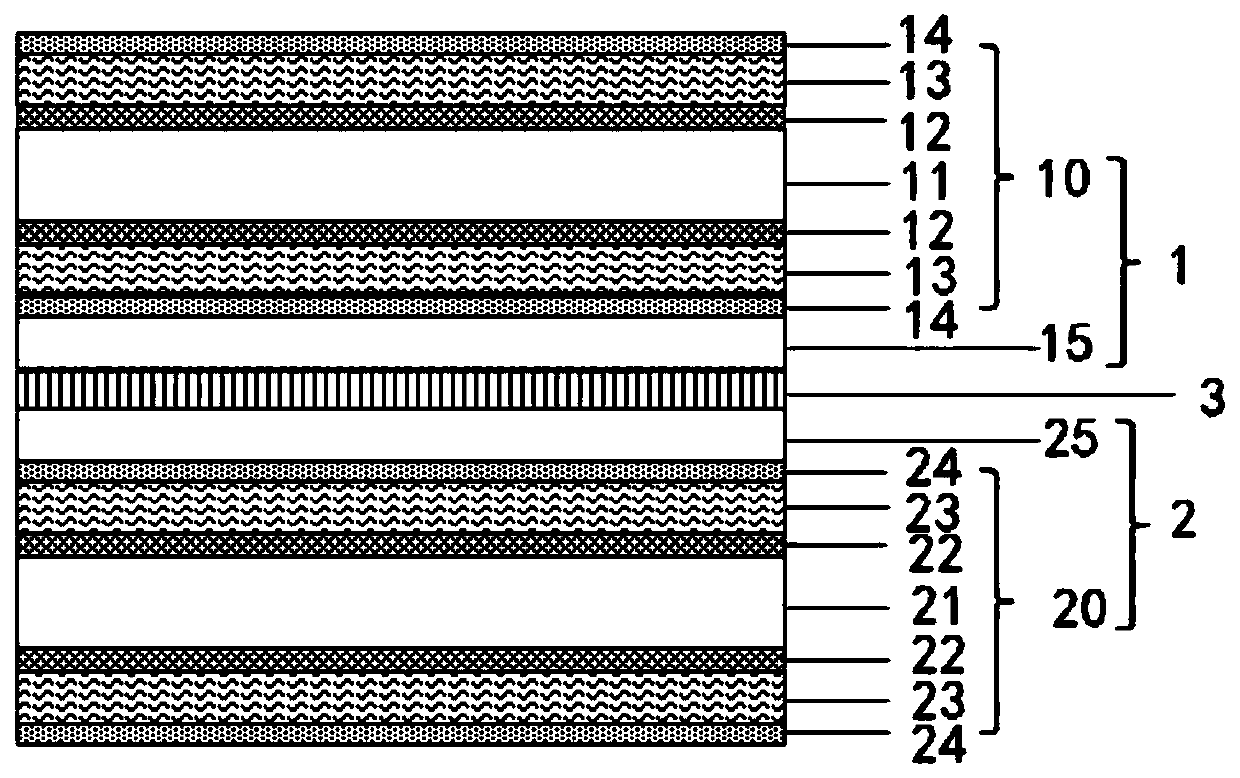

Image

Examples

preparation example Construction

[0037] A method for preparing a positive current collector, comprising the steps of:

[0038] S1. First, corona treatment is performed on the surface of the plastic film to be coated, and then the reel plastic film is placed in the vacuum chamber of the double-sided reciprocating electron beam evaporation coating machine, the vacuum chamber is sealed, and the vacuum is gradually evacuated until the vacuum degree reaches 3×10 -3 -6×10 -3 Pa, using electron gun to accelerate electron bombardment collision evaporation raw material Al 2 o 3 , adjust the unwinding speed, winding speed and evaporation, Al 2 o 3 Absorb heat and vaporize, forming a layer of Al on the surface of the moving film 2 o 3 Plating layer, that is, the adhesion enhancing layer;

[0039] S2. Al plating obtained in S1 2 o 3 The film is placed in the vacuum chamber of the double-sided reciprocating evaporation coating machine, the vacuum chamber is sealed, and the vacuum is vacuumed step by step until the...

Embodiment 1

[0055] A preparation method for a lithium battery containing a current collector, comprising the steps of:

[0056] S1. After the positive electrode current collector is prepared, the positive electrode slurry is coated on the positive electrode current collector, and the positive electrode sheet is obtained after vacuum drying; the positive electrode slurry is made of lithium iron phosphate (or lithium titanate, ternary material), Materials such as PVDF and C are added to the solvent N-methylpyrrolidone and mixed and stirred; among them, LiFePO 4 , The mass ratio of PVDF and C is 86%: 8%: 6%; the coating thickness of positive electrode slurry is 0.1-0.2mm;

[0057] S2. After the negative electrode collector is prepared, the negative electrode slurry is coated on the negative electrode collector, and the negative electrode sheet is obtained after vacuum drying; the negative electrode slurry is obtained by adding graphite, PVDF and VGCF to solvent water and mixing and stirring ...

Embodiment 2

[0061] Referring to Example 1, the difference from Example 1 is that in S1, the mass ratio of lithium iron phosphate (or lithium titanate, ternary material), PVDF and C is 88%: 7%: 5%; in S2, graphite The mass ratio of , PVDF and VGCF is 90%: 7%: 3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com