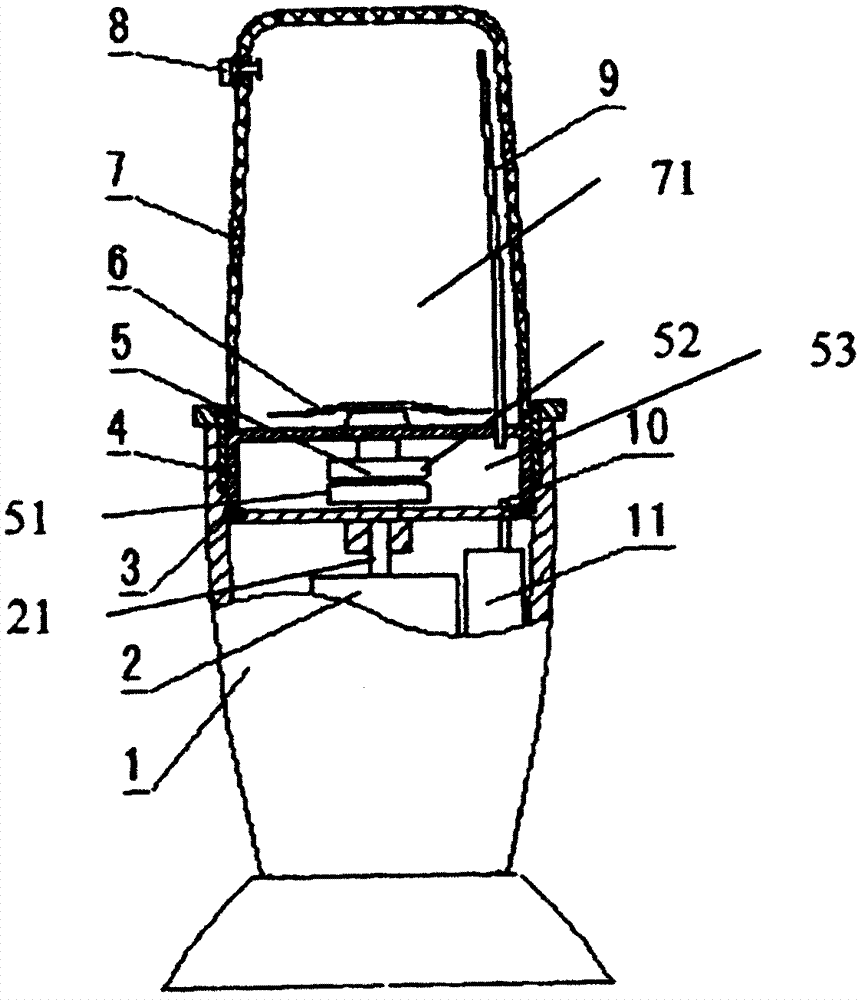

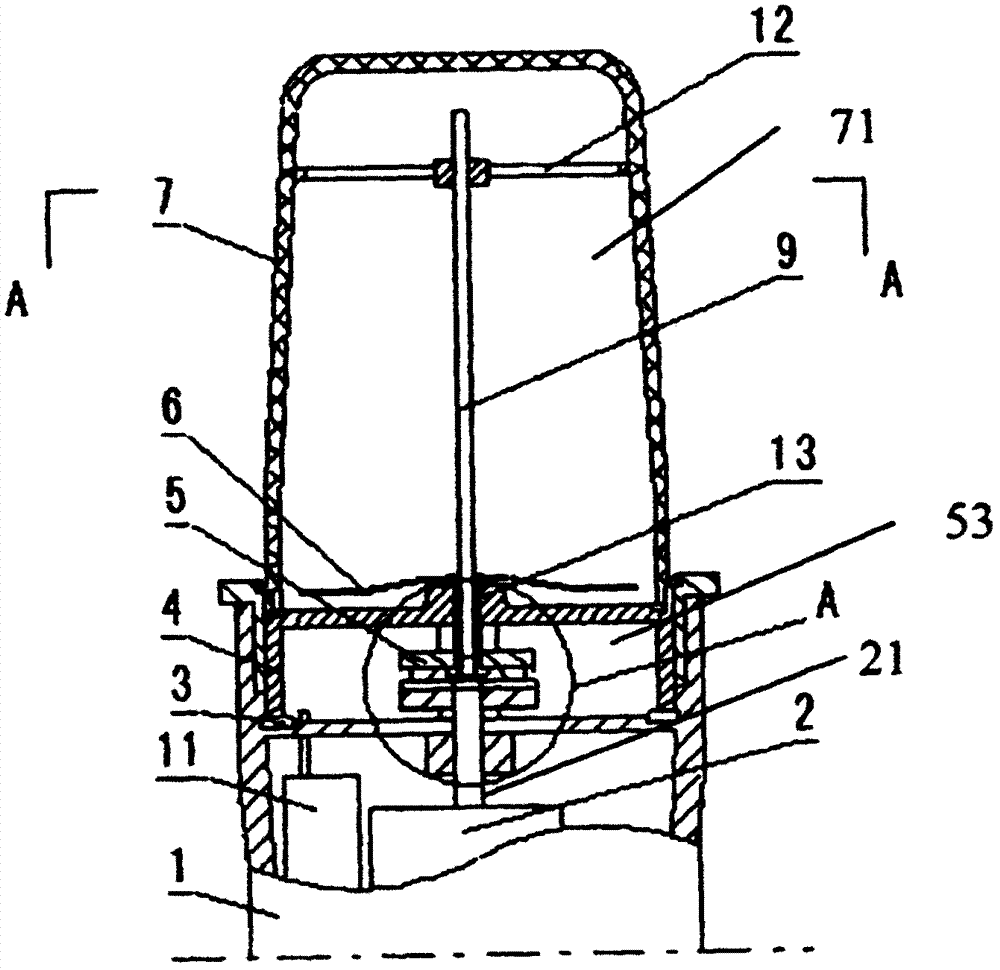

Vacuum food crushing and stirring machine

A blender and food technology, which is applied in household machinery for filtering food, household utensils, applications, etc., and can solve problems such as inconvenient cleaning and complicated structure of feeding cups

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

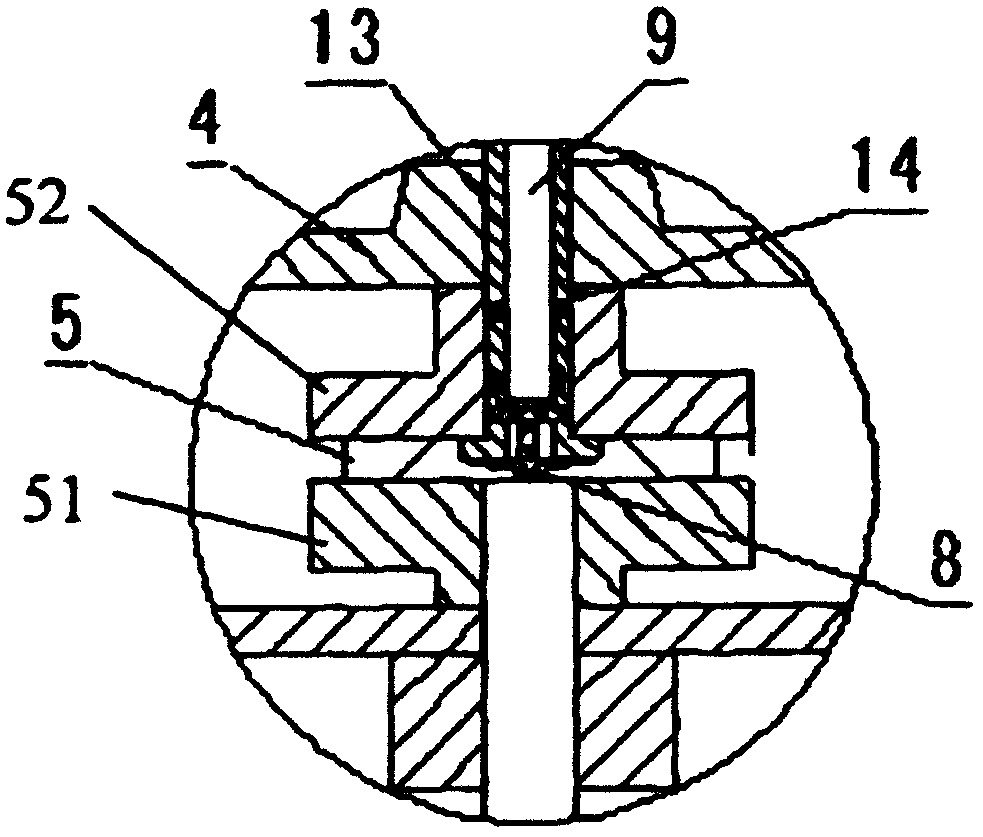

Method used

Image

Examples

Embodiment 3

[0128] The deflation valve of embodiment 3 can adopt figure 1 Example 1 or figure 2 The structure and installation position of embodiment 2. Or there is a through vent hole at the bottom of the coupling cavity (that is, the upper wall or top wall of the support), and the vent hole is provided with an electric control valve 8 ( Figure 5 Not shown. When the electric control valve 8 is set here, the space in the base 1 needs to be communicated with the outside atmosphere), and the electric control valve is electrically connected with the control circuit board. After vacuumizing and making juice, the control circuit board sends a control signal to make the electric control valve open and remove the vacuum in the shaft coupling cavity 53 .

[0129] Such as Image 6 In the shown embodiment 4, the cup body 7 has an upper end cover 15, and a sealing ring is provided between the skirt of the upper end cover (ie, sealing cover) 15 and the port of the cup body. The upper end cove...

Embodiment 1

[0137] The structural form of the vacuum pump and the control mechanisms of the motor and the vacuum pump in Embodiment 1 are also applicable to other embodiments.

[0138] The inverted cup and the upper open cup in the present invention can also adopt a double-layer structure cup wall and / or a double-layer structure cup bottom. The middle of the double-layer structure cup wall and / or the double-layer structure cup bottom is an air interlayer, vacuum or filled with other thermal insulation materials.

[0139] A detachable movable filter screen can also be arranged at the cup body port of the upper open cup in the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com