Induction coil for high-frequency welding of large-diameter pipeline

A high-frequency welding and large-diameter tube technology, applied in the field of induction coils, can solve the problems of large welding area coverage, strict requirements for welding temperature and temperature, and unsatisfactory welding effect, so as to improve uniformity, ensure welding quality and Service life, the effect of increasing the welding temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

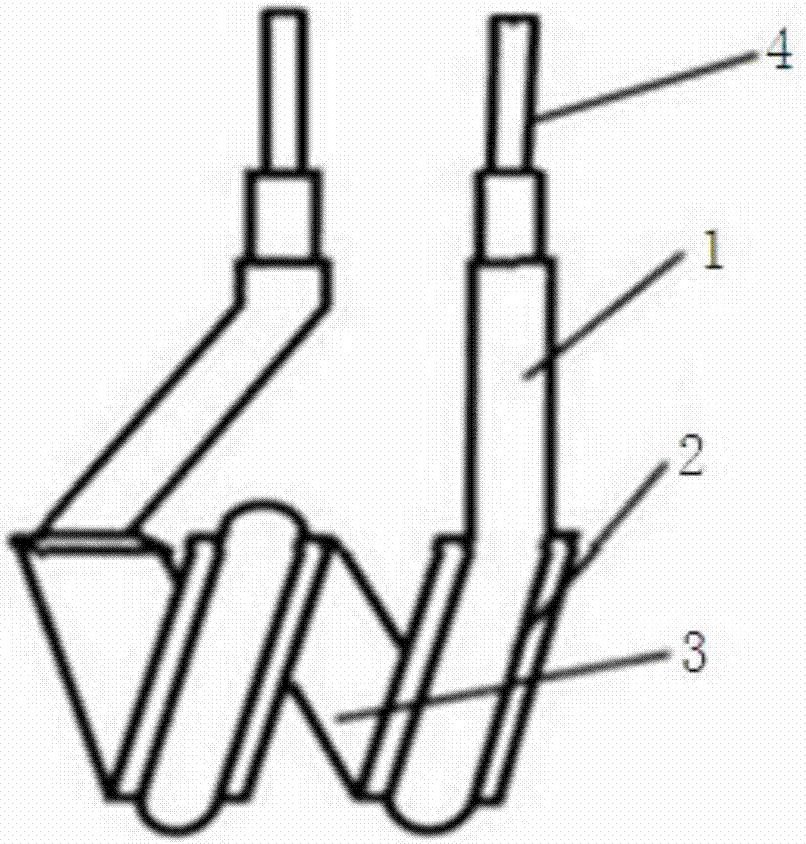

[0011] See attached figure 1 As shown, an induction coil for high-frequency welding of large-diameter pipelines includes a copper pipe 1, a copper strip 2 and an insulating tape 3. Firstly, the copper strip 2 is wound on a mold, and then the copper pipe 1 is wound on the On the copper strip 2 , the contact parts of the copper pipe 1 and the copper strip 2 are fully welded, and the insulating tape 3 is used to wrap the welded copper pipe 1 and copper strip 2 . The outer diameter of the mold is 15%-20% larger than the diameter of the large-diameter pipeline, and the number of winding circles is 1-3 circles. The processed induction coil can be used after being installed on the high-frequency welding. In order to ensure that the induction coil has the impedance of low voltage and high current and the uniformity of welding temperature, the diameter of the copper pipe 1 is 6.5-12.5 mm, and a cooling water pipe 4 is provided inside it, and the thickness of the copper strip 2 is 2-3m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com