Edge folding and rope stringing welding machine and application method thereof

A side-threading and welding machine technology, which is applied in the field of edge-folding rope welding machines, can solve the problems of no cooling buffer equipment, unsatisfactory welding effect, single welding function, etc., and achieve good welding effect, simple structure, and convenient operation and use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

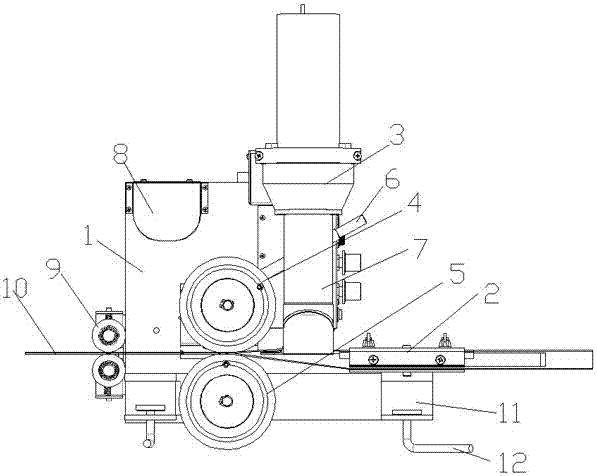

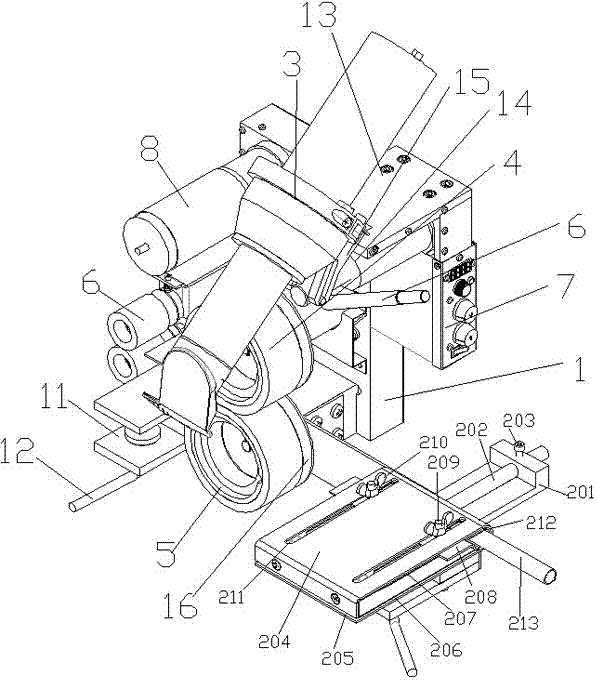

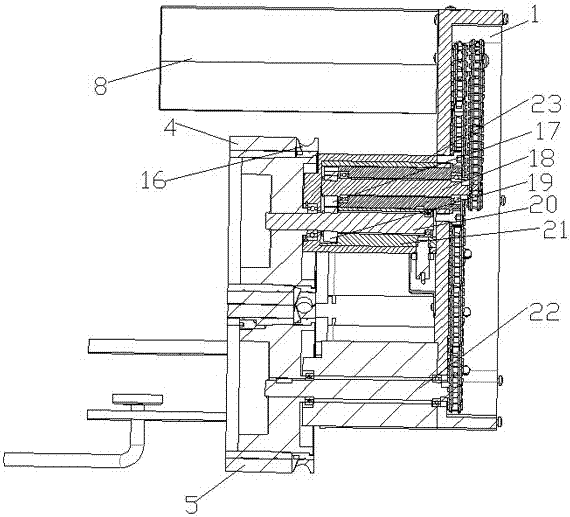

[0022] Such as Figure 1-4 As shown, a hemming rope welding machine includes a frame 1, on which a hemming rope guide 2, a heat gun 3, a hemming welding structure, and a cooling aid are sequentially arranged along the direction from input to output. Pressing roller 9, described crimp welding structure comprises the upper pressing wheel 4 that turns to opposite, lower pressing wheel 5, described frame 1 is provided with the speed regulating motor 8 that drives upper pressing wheel 4, lower pressing wheel 5 to rotate, so The lower pressing wheel 5 is installed on the front end of the lower rotating shaft 22, the rear end of the lower rotating shaft 22 is provided with a sprocket A, the upper pressing wheel 4 is installed on the front end of the upper rotating shaft 20, the upper rotating shaft 20 is provided with a reversing shaft 18, and the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com