Concave natural rubber film-coated gasket and its production process

A technology of natural rubber and production process, applied in rubber layered products, metal processing, layered products, etc., can solve the problems of reagent mixing, inaccurate test results of reagents, and insufficient resilience, and achieve excellent self-sealing performance and ease of use. The effect of identifying the lamination surface and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

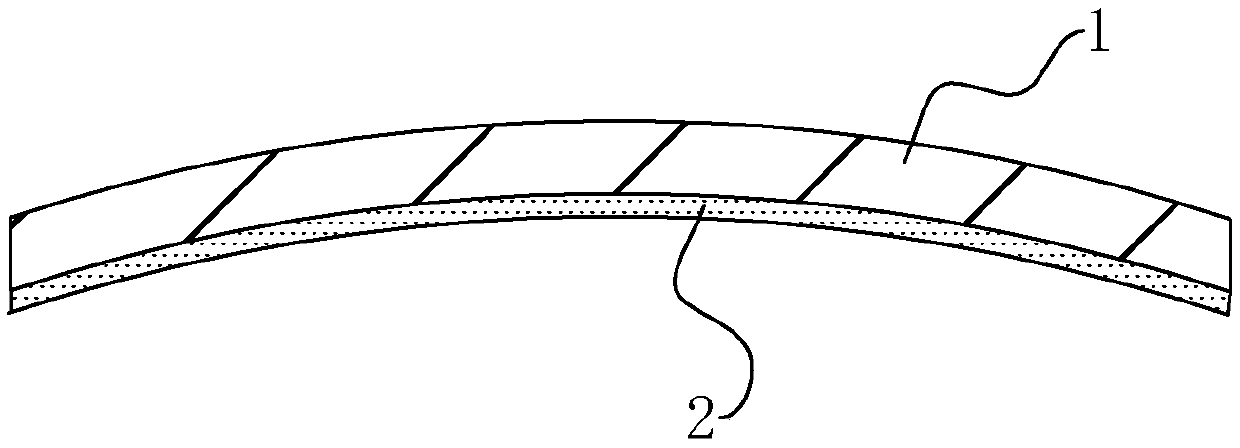

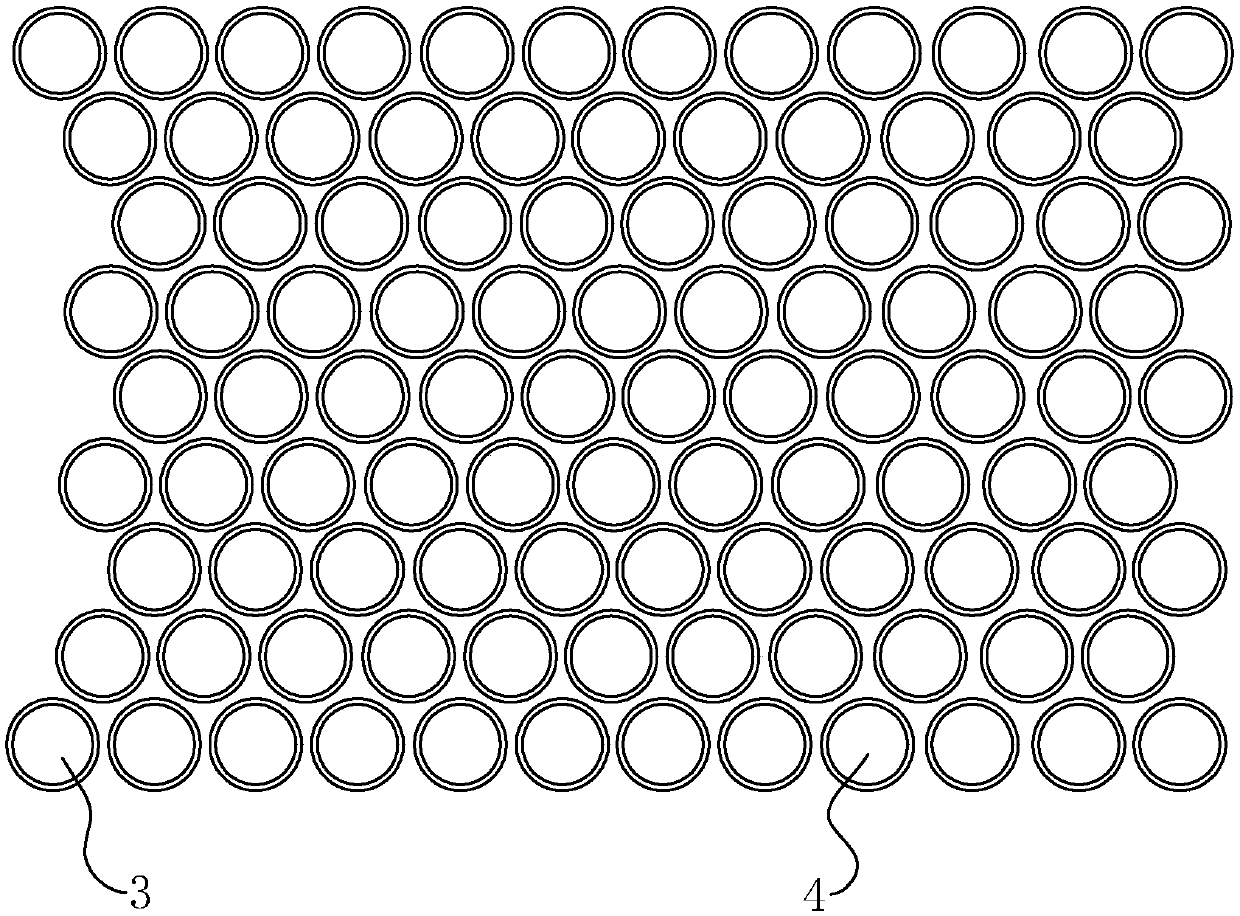

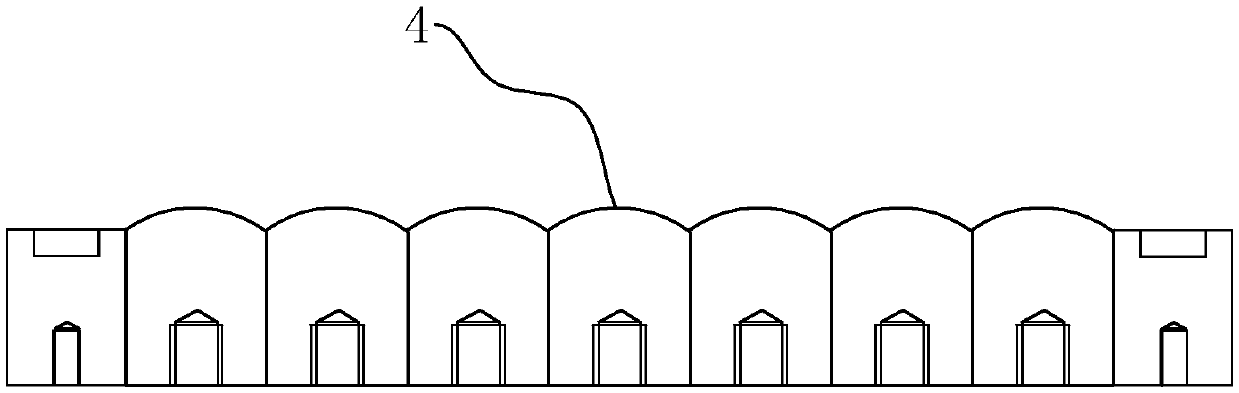

[0053] Embodiment 1: Concave natural rubber coated gasket, such as figure 1As shown, including the natural rubber layer 1 and the coating layer 2, the components and their corresponding parts by weight are shown in Table 1, and are prepared by the following steps:

[0054] S1, natural rubber layer 1 ingredient mixing, banburying: Weigh the natural rubber in the natural rubber layer 1 in corresponding parts by weight, and stearic acid, titanium dioxide, iron oxide red, anti-aging agent 264, vaseline in corresponding parts by weight, fully mixing to form the first mixture, and banburying the first mixture, during the banburying process, adding heavy calcium carbonate, accelerator and zinc oxide in corresponding parts by weight, fully banburying to form the second mixture;

[0055] S2, natural rubber layer 1 rubber mixing, sheet production: add the corresponding parts by weight of sulfur to the second mixture obtained in step S1 for mixing. And regular natural rubber film;

[0...

Embodiment 2-6

[0058] Embodiment 2-6: Concave natural rubber film-coated gasket. The difference from Embodiment 1 is that the components and their corresponding parts by weight are shown in Table 1.

[0059] Components and their corresponding parts by weight in Table 1 Embodiment 1-6

[0060]

Embodiment 7

[0061] Embodiment 7: Concave natural rubber film-coated gasket. The difference from Embodiment 1 is that all accelerators are accelerators TRA.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com