High weather-resistant spray-free metal-imitating ABS composite material

A composite material and spray-free technology, applied in the field of polymer materials, can solve the problems of weather resistance, easy yellowing, and affecting the mechanical properties of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The preparation method of described modified ABS is as follows:

[0043] Add ABS, 4-[2-(3,5-dihydroxyphenyl)vinyl]-1,2-benzenediol, and diacrylaldehyde pentaerythritol into the reactor according to the weight ratio, and raise the temperature to 80-90°C. Add the initiator in 3 batches successively, and react for 6-10 hours to obtain the modified ABS; the weight ratio of the ABS to the initiator is 1:0.002, and the initiator is azobisisobutyronitrile.

[0044] In the present invention, copolymerize ABS with 4-[2-(3,5-dihydroxyphenyl)vinyl]-1,2-benzenediol and diacrylaldehyde pentaerythritol to form modified ABS, 4-[ The introduction of phenolic hydroxyl groups in 2-(3,5-dihydroxyphenyl)vinyl]-1,2-benzenediol and the addition of diacrylaldehyde pentaerythritol can promote the weather resistance of ABS and improve the resistance of modified ABS and The degree of cross-linking of ABS.

[0045] The preparation method of described spray-free imitation metal masterbatch is as...

Embodiment 1

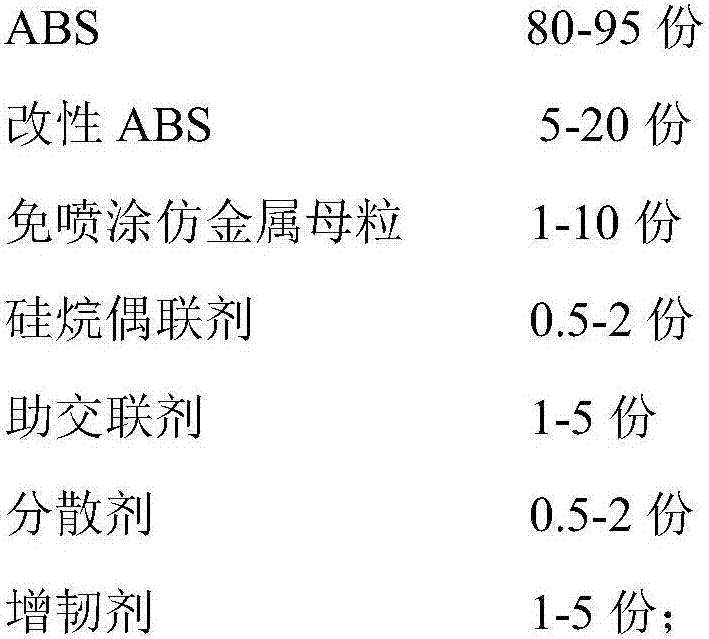

[0078] The high weather resistance spray-free metal-like ABS composite material, calculated by weight, includes the following raw materials:

[0079]

[0080] Wherein, the modified ABS is a copolymer of ABS and 4-[2-(3,5-dihydroxyphenyl)vinyl]-1,2-benzenediol and diacrylaldehyde pentaerythritol, and the ABS and the The weight ratio of said 4-[2-(3,5-dihydroxyphenyl)vinyl]-1,2-benzenediol and said diacrylaldehyde pentaerythritol is 1:0.8:0.16; said spray-free imitation Metal masterbatch is described modified ABS coated pearlescent metallic pigment; Described silane coupling agent is KH570; Described co-crosslinking agent is sulfonated octaphenyl-POSS, octa(aminophenyltrioxysilane); The weight ratio of the sulfonated octaphenyl-POSS to the octa(aminophenyltrioxysilane) is 1:0.6; the dispersant is vinylbisstearamide; the antioxidant is antioxidant 1010, Antioxidant 1035; the weight ratio of the antioxidant 1010 and the antioxidant 1035 in the antioxidant is 1:1.2; the light s...

Embodiment 2

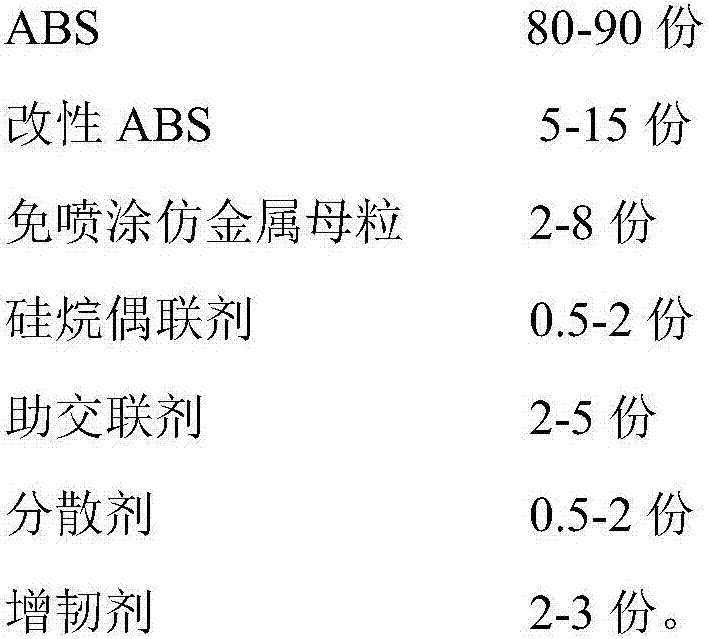

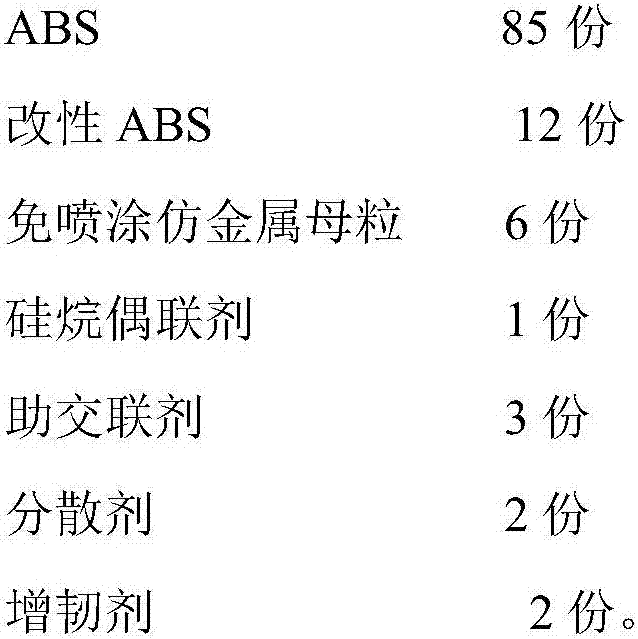

[0095] The high weather resistance spray-free metal-like ABS composite material, calculated by weight, includes the following raw materials:

[0096]

[0097]

[0098] Wherein, the modified ABS is a copolymer of ABS and 4-[2-(3,5-dihydroxyphenyl)vinyl]-1,2-benzenediol and diacrylaldehyde pentaerythritol, and the ABS and the The weight ratio of said 4-[2-(3,5-dihydroxyphenyl)vinyl]-1,2-benzenediol and said diacrylaldehyde pentaerythritol is 1:0.8:0.16; said spray-free imitation Metal masterbatch is described modified ABS coated pearlescent metallic pigment; Described silane coupling agent is KH570; Described co-crosslinking agent is sulfonated octaphenyl-POSS, octa(aminophenyltrioxysilane); The weight ratio of the sulfonated octaphenyl-POSS to the octa(aminophenyltrioxysilane) is 1:0.6; the dispersant is vinylbisstearamide; the antioxidant is antioxidant 1010, Antioxidant 1035; the weight ratio of the antioxidant 1010 and the antioxidant 1035 in the antioxidant is 1:1.2;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com