A kind of foam well washing fluid and preparation method thereof

A well-flushing fluid and foam technology, which is applied in the field of foam well-flushing fluid, can solve the problems of not being able to meet the requirements of foam well-flushing construction, foam volume and foam stability, etc., achieve excellent oil washing ability, and reduce oil-water interfacial tension , the effect of excellent foaming performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

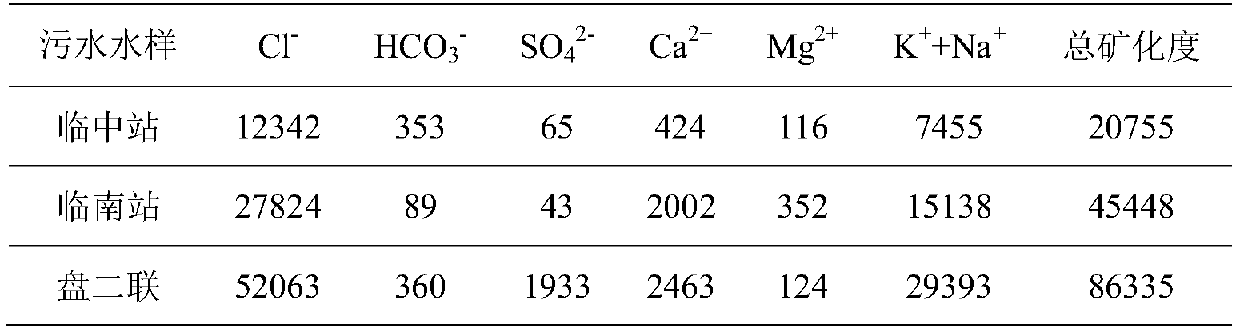

[0030] The present embodiment adopts the foam well-flushing fluid prepared from Linzhong station oilfield sewage, comprising the following components in weight percent: formaldehyde (bactericide) 0.25%, tetrasodium hydroxyethylidene diphosphonate (ion stabilizer) 0.03%, twelve Alkyl hydroxypropyl sulfobetaine (foaming agent) 0.1%, hydroxypropyl guar gum (thickener) 0.2%, sodium tetraborate (crosslinking agent) 0.025%, and the balance is Linzhong station oilfield sewage, The sum of the weight percentages of each component is 100%.

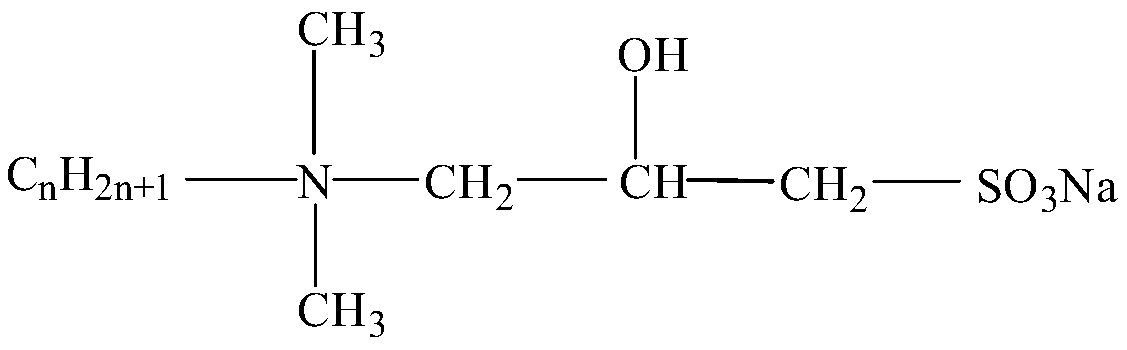

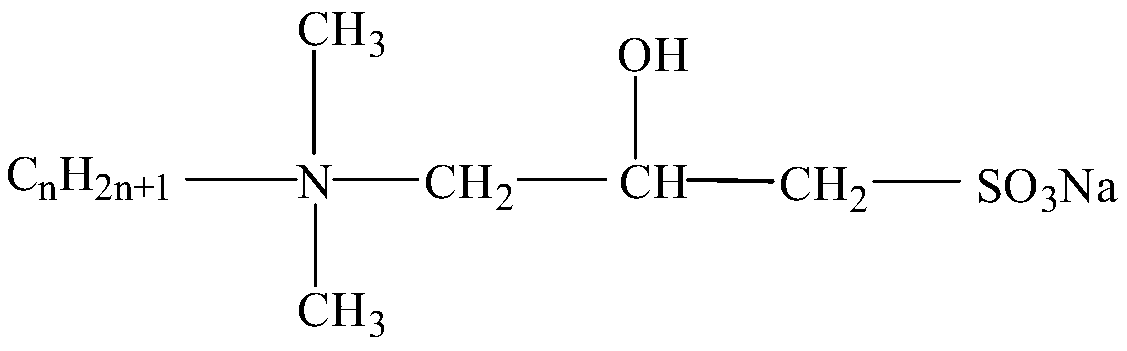

[0031] Wherein the foaming agent is lauryl hydroxypropyl sulfobetaine, and its molecular formula is:

[0032]

[0033] The molecular weight is 374.

[0034] The preparation method of above-mentioned foam well-washing fluid, comprises the following steps:

[0035] (1) Get the oilfield sewage and place it in the Wuyin mixer, under stirring conditions, add formaldehyde, tetrasodium hydroxyethylidene diphosphonate, dodecyl sulfobetaine, hydroxyprop...

Embodiment 2

[0038] The present embodiment adopts the foam well-flushing fluid prepared from Linnan station oilfield sewage, comprising the following components in weight percent: 0.45% glutaraldehyde (bactericide), pentasodium diethylenetriaminepentamethylenephosphonate (ion stabilizer) 0.035%, tetradecyl hydroxypropyl sulfobetaine (foaming agent) 0.15%, hydroxypropyl guar gum (thickener) 0.3%, sodium tetraborate (crosslinking agent) 0.035%, the balance is Lin For South Station oilfield sewage, the sum of the weight percentages of each component is 100%.

[0039] Wherein the foaming agent is tetradecyl hydroxypropyl sulfosulfobetaine, and its molecular formula is:

[0040]

[0041] The molecular weight is 402.

[0042] The preparation method of above-mentioned foam well-washing fluid, comprises the following steps:

[0043] (1) Take the oilfield sewage and put it in the Wuyin mixer. Under the stirring condition, add the glutaraldehyde, diethylenetriamine pentamethylene phosphonate pe...

Embodiment 3

[0046] The present embodiment adopts the foam well-washing fluid prepared from Panerian oilfield sewage, including the following components in weight percent: 0.5% glutaraldehyde (bactericide), 0.04% sodium ethylenediamine tetramethylene phosphonate (ion stabilizer) , cetyl hydroxypropyl sulfobetaine (foaming agent) 0.25%, carboxymethyl hydroxypropyl guar gum (thickener) 0.3%, sodium tetraborate (crosslinking agent) 0.045%, the balance is For Pan'erlian oilfield sewage, the sum of the weight percentages of each component is 100%.

[0047] Wherein the foaming agent is cetyl hydroxypropyl sulfosulfobetaine, and its molecular formula is:

[0048]

[0049] The molecular weight is 430.

[0050] The preparation method of above-mentioned foam well-washing fluid, comprises the following steps:

[0051] (1) Take Pan Erlian oilfield sewage and place it in the Wuyin mixer. Under stirring conditions, add glutaraldehyde, sodium ethylenediamine tetramethylene phosphonate, cetyl hydroxy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com