Durable ultrathin asphalt skid-resistant surface layer pavement structure and construction method

A technology of pavement structure and asphalt pavement, which can be applied to cohesive pavement paved on site, roads, roads, etc., which can solve problems such as poor drainage and anti-skid performance, insufficient interlayer bonding ability, and loud vehicle driving noise. Achieve good durability, good road smoothness, and good skid resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions of the present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

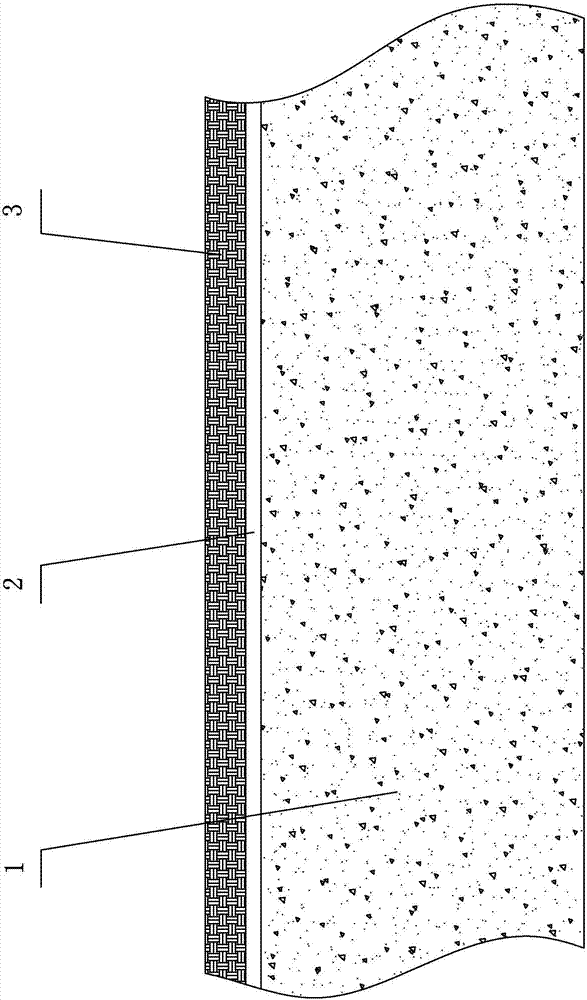

[0024] The technical scheme of the durable ultra-thin asphalt anti-skid surface pavement structure of the present invention comprises the concrete pavement base 1 or the asphalt pavement base, the non-stick wheel interlayer sticky layer 2 of the middle layer and the ultra-thin asphalt anti-skid surface 3 of the upper layer, such as figure 1 shown.

[0025] The interlayer adhesive layer 2 of the non-stick wheel is coated on the concrete pavement base 1 or the asphalt pavement base, and the coating material adopts hot-melt modified asphalt, and the coating amount of the hot-melt modified asphalt adopts 0.1kg / m 2 ~1kg / m 2 , non-stick wheel hardening time is less than 3 minutes, such as figure 1 shown.

[0026] The ultra-thin asphalt anti-skid surface layer 3 is spread on the non-stick wheel interlayer sticky layer 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com