Anti-overturning steel bar support used for cantilever coping concrete pouring and installation method of steel bar support

An anti-overturning and concrete technology, which is applied in buildings, bridges, bridge construction, etc., can solve the problems of pile driving and pile pulling equipment with many labor resources, poor control of structural safety factor, poor economic benefits, etc., and achieves convenient and quick installation and disassembly , Improve operating efficiency and reduce labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The following non-limiting examples serve to illustrate the invention.

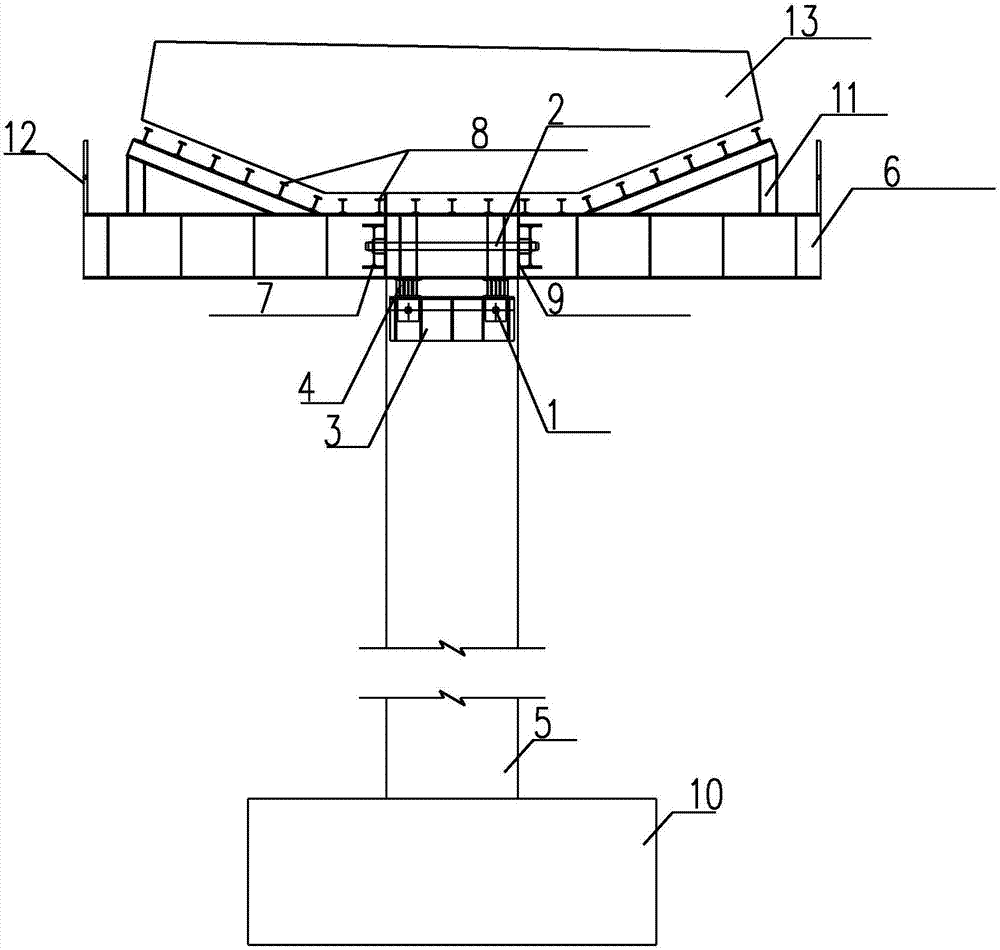

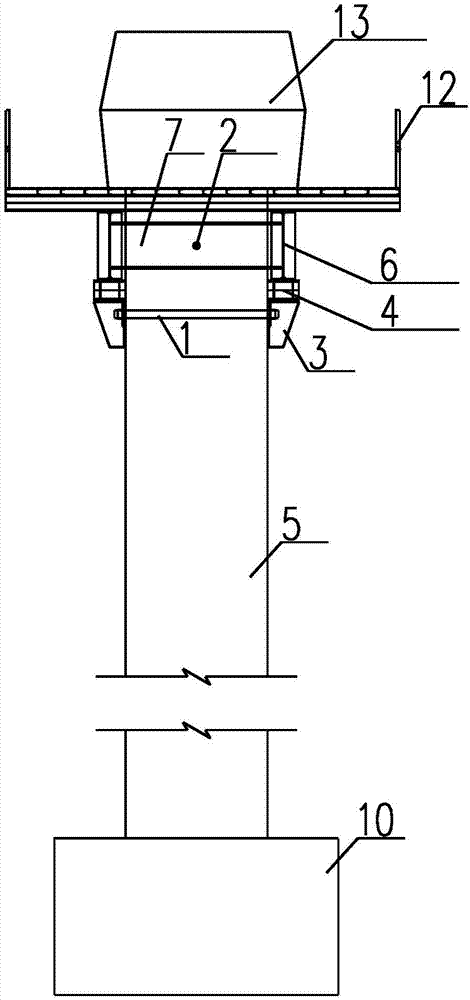

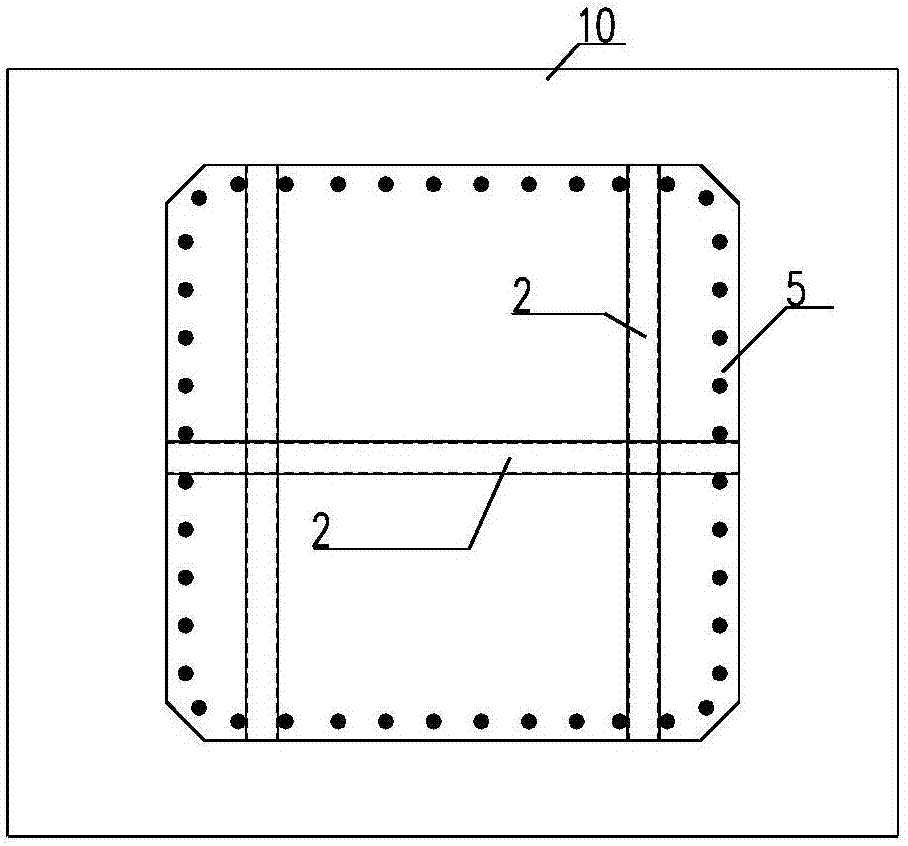

[0048] reference Figure 1 to 3 As shown, an anti-overturning steel bar support for cantilever cover beam concrete pouring is composed of six parts: load-bearing steel bar 1, anti-overturning steel bar 2, corbel 3, unloading block 4, support beam and formwork system. The pier body 5 is prefabricated with steel rod holes for the load-bearing steel rods 1 and the anti-overturning steel rods 2 to pass through. The load-bearing steel rods 1 are arranged horizontally along the longitudinal bridge direction at least 2 (as shown in the figure of this embodiment) , The anti-overturning steel rod 2 is horizontally arranged at least one along the transverse bridge direction, the load-bearing steel rod 1 also passes through the corbel 3 to fix the corbel 3 on the side of the pier 5, and the main beam 6 of the support beam is provided above the corbel 3, The main beam 6 is supported by the unloading block 4 arra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com