A protective structure for slip-form construction of exhaust chimney in painting workshop

A technology of exhaust chimney and protective structure, which is applied in the direction of housing structure support, housing structure support, and scaffolding supported by housing structure, etc., can solve the problems of increasing the probability of safety accidents, achieve green construction, improve safety factor, and maintain buffering effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

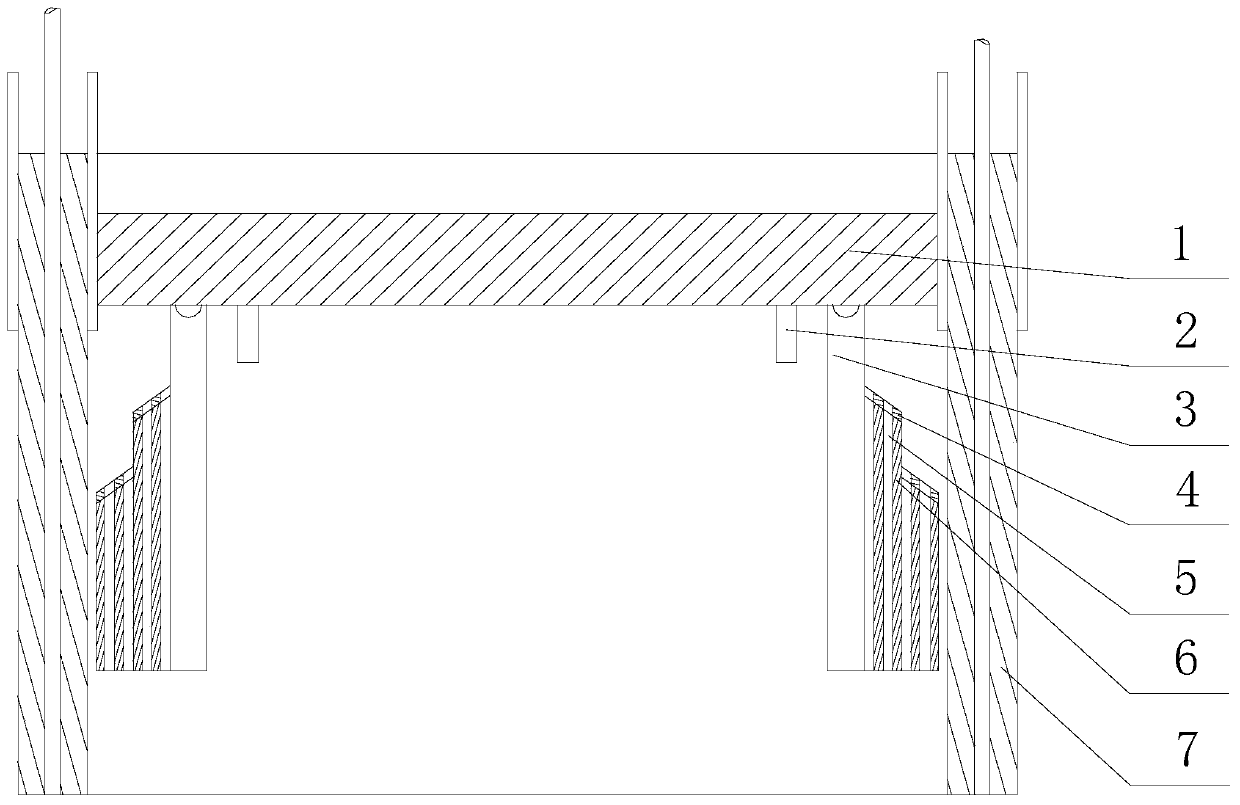

[0022] Such as figure 1As shown, this embodiment includes a rectangular support platform 1, four baffles 3 are hingedly arranged on the lower surface of the support platform 1 along the outline edge of the support platform 1, and on the outside of each of the baffles 3 At least two guide blocks 6 are arranged on the wall, and there is a rebound surface on the upper end surface of each guide block 6, and the rebound surface is inclined in a direction away from the support platform 1 along the horizontal direction, A flow passage 5 penetrating through the guide block 6 is opened on the guide block 6 along the vertical direction. In view of the prior art, when the support platform 1 cleans the concrete block, there is a gap between each end surface of the support platform 1 and the inner wall of the exhaust chimney 7, and the concrete block moves from top to bottom along the gap, and the falling process The concrete block will constantly collide with the inner wall of the exhaus...

Embodiment 2

[0027] Such as figure 1 As shown, in this embodiment, on the basis of Embodiment 1, a plurality of limiting plates 2 are provided on the lower surface of the support platform 1 , and the limiting plates 2 are facing the inner sidewall of the baffle plate 3 . When the large-diameter concrete block falls from the gap to contact with the guide block 6, the instantaneous impact force received by the guide block 6 is relatively large, and the impact force will drive the baffle plate 3 and the guide block 6 around the baffle plate 3. The hinge point makes a relatively large swing. At this time, before the baffle plate 3 and the guide block 6 return to their original positions, there is no blocking unit in the area below the gap to buffer the falling trend of the remaining concrete blocks, which causes the support platform 1 The protective structure below fails, and the applicant has provided a limit plate 2 corresponding to the baffle 3 on the lower surface of the support platform 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com